oldmoparsrule

Well-Known Member

I have been waiting for a while to start this portion of my project. I already have the '73 Disk brakes on the front, so this is the next step in the evolution.

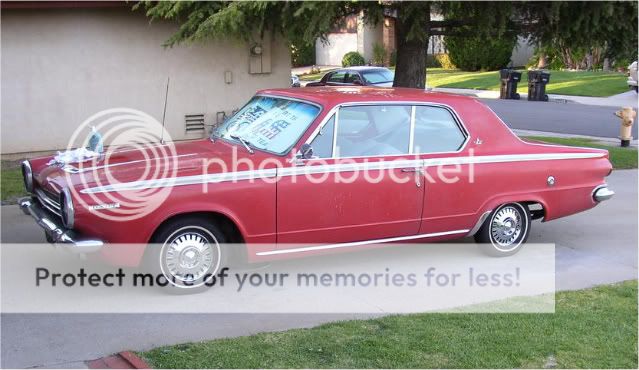

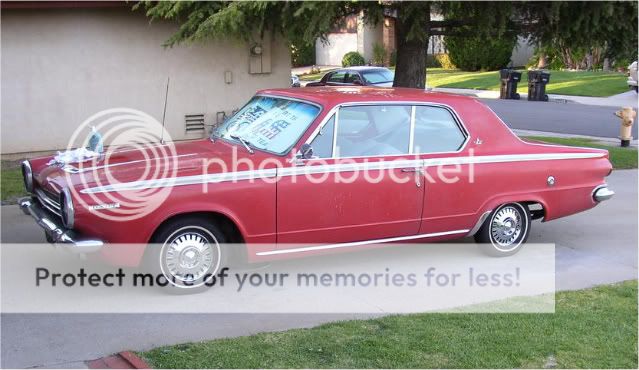

Here is what my car looked like the day I brought her home, before the disk brakes, etc...It is a 225/auto, GT, Red with Red interior. I bought it from an older lady in Santa Monica.

Here is the original tire on the right, and the new tire on the left. I am going from 13's to the 315x60x15 Mickey Thompson Drag Radial, on Weld 15x10's with 5 inches of backspacing.

The first step was the get the old 7 1/4 out of the way. We removed it with the leaf springs, etc...at the same time.

With the little axle out of the way, we wanted to see how the new tires would fit in the uncut wheel well...Sorry about the blurry pictures, I must have been shaking with excitement...or caffeine.

You can see that the wheel is hitting in a few places. The original ride height was about 21.5 inches at the lip of the fender. In these pictures, the fender is at about 27 inches. I thing the final ride height will be about 1.5 inches lower in the back. It definitely sits up high in the back, but I think it looks pretty cool.

The next step was the removal of the gas tank, and the associated hardware...

Here are a few shots after cutting the inside of the wheel well.

Here are a few final shots after we finally removed the metal in the original wheel tub...so that it is flush with the frame. This is probably real close to there the wheel will sit, although the car will probably be 1.5 to 2 inches lower. I am running a set of Mancini Super Stock springs, which coupled with the tall tire will give it so much height in the rear. The first shot included my Dad who was an incredible help with this. Honestly, this is most of the reason I do these projects...to hang out with my dad.

Yes, that is the trunk, hood and seats all stacked on the top of the car...I have to be able to get my wife's Pilot into the garage...or I am busted 8)

I still have a lot of work to do to finish the one wheel tub...then to move on to the other side. I imagine we spent about 4 hours getting everything removed, then another 4 to 5 hours getting the one side ready to begin welding in the filler pieces.

This has been a great day.

Thank You!

OldMoparsRule

Here is what my car looked like the day I brought her home, before the disk brakes, etc...It is a 225/auto, GT, Red with Red interior. I bought it from an older lady in Santa Monica.

Here is the original tire on the right, and the new tire on the left. I am going from 13's to the 315x60x15 Mickey Thompson Drag Radial, on Weld 15x10's with 5 inches of backspacing.

The first step was the get the old 7 1/4 out of the way. We removed it with the leaf springs, etc...at the same time.

With the little axle out of the way, we wanted to see how the new tires would fit in the uncut wheel well...Sorry about the blurry pictures, I must have been shaking with excitement...or caffeine.

You can see that the wheel is hitting in a few places. The original ride height was about 21.5 inches at the lip of the fender. In these pictures, the fender is at about 27 inches. I thing the final ride height will be about 1.5 inches lower in the back. It definitely sits up high in the back, but I think it looks pretty cool.

The next step was the removal of the gas tank, and the associated hardware...

Here are a few shots after cutting the inside of the wheel well.

Here are a few final shots after we finally removed the metal in the original wheel tub...so that it is flush with the frame. This is probably real close to there the wheel will sit, although the car will probably be 1.5 to 2 inches lower. I am running a set of Mancini Super Stock springs, which coupled with the tall tire will give it so much height in the rear. The first shot included my Dad who was an incredible help with this. Honestly, this is most of the reason I do these projects...to hang out with my dad.

Yes, that is the trunk, hood and seats all stacked on the top of the car...I have to be able to get my wife's Pilot into the garage...or I am busted 8)

I still have a lot of work to do to finish the one wheel tub...then to move on to the other side. I imagine we spent about 4 hours getting everything removed, then another 4 to 5 hours getting the one side ready to begin welding in the filler pieces.

This has been a great day.

Thank You!

OldMoparsRule