what did I win ? 5 dollar coupon? lolYou win, your right....

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

318 build #2 "cost minded" for the '74 Duster

- Thread starter 318willrun

- Start date

-

Page 11, just trying to keep the current parts list on every page so those joining late can quickly view where we are at.

* '94 5.2 magnum engine

* 20-745-9 Comp Cam Roller

* Hughes Spring Kit with 1110 springs (springs/locks/retainers)

* Weiand Stealth Intake 8022

Also, we have torn the top half of the 5.2 down. Cylinder walls still have factory hone marks and rocker assembly were not rusty, but a little gunky. Onward!

* '94 5.2 magnum engine

* 20-745-9 Comp Cam Roller

* Hughes Spring Kit with 1110 springs (springs/locks/retainers)

* Weiand Stealth Intake 8022

Also, we have torn the top half of the 5.2 down. Cylinder walls still have factory hone marks and rocker assembly were not rusty, but a little gunky. Onward!

Be interesting to see how well the 5.2 magnum respond to basic hot rodding sure will surprise a few.Page 11, just trying to keep the current parts list on every page so those joining late can quickly view where we are at.

* '94 5.2 magnum engine

* 20-745-9 Comp Cam Roller

* Hughes Spring Kit with 1110 springs (springs/locks/retainers)

* Weiand Stealth Intake 8022

Also, we have torn the top half of the 5.2 down. Cylinder walls still have factory hone marks and rocker assembly were not rusty, but a little gunky. Onward!

j par

Well-hung Member

You win the discussion. I'm just tired of trying to go back and forth. It's just not worth my time anymore. It's obvious you know much more about drag racing and mopars than I do by the fact alone that you have a Youboob channel .what did I win ? 5 dollar coupon? lol

The best of luck on your build and I'll be watching..

Hughes engines has lots of flow data on small and big block heads.Where do you get your information frim?

I'm building a 5.2, and that is what I've been posting in this thread. You think I'm building a channel in this thread .You win the discussion. I'm just tired of trying to go back and forth. It's just not worth my time anymore. It's obvious you know much more about drag racing and mopars than I do by the fact alone that you have a Youboob channel ..

The best of luck on your build and I'll be watching..

Anyways, back to the 5.2 build.

Last edited:

j par

Well-hung Member

Your rightI'm building a 5.2, and that is what I've been posting in this thread. You think I'm building a channel in this thread .Truth is, I really don't think of my channel when I'm on FABO unless video footage coverage is on point to topic.

Anyways, back to the 5.2 build.

....

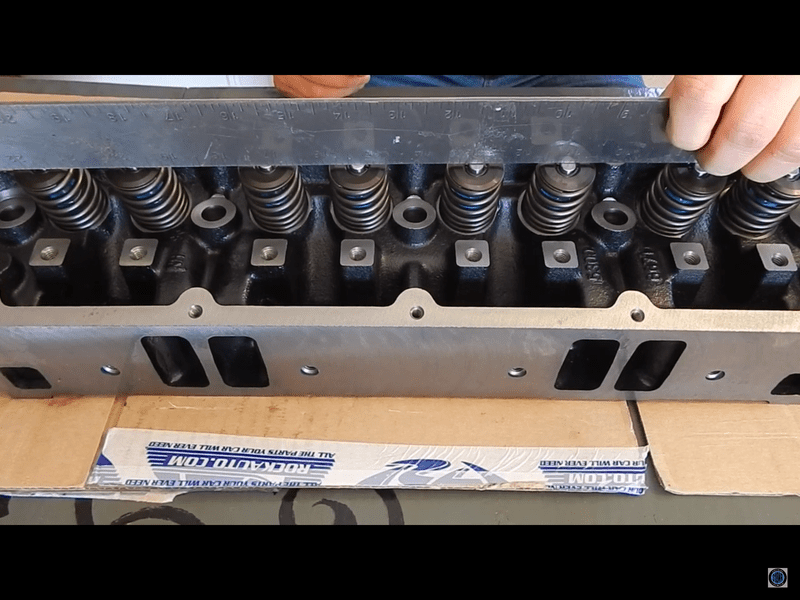

....Here are the heads that we settled on for the 5.2 Magnum build. THESE COULD HAVE DESTROYED THE ENGINE!! ALWAYS INSPECT "OOTB" HEADS!!!

And for those that wish to see more than just the photos above, and see how we discovered the heads contaminants, here is the video.

And for those that wish to see more than just the photos above, and see how we discovered the heads contaminants, here is the video.

Here are the heads that we settled on for the 5.2 Magnum build. THESE COULD HAVE DESTROYED THE ENGINE!! ALWAYS INSPECT "OOTB" HEADS!!!

View attachment 1716007944

View attachment 1716007946

And for those that wish to see more than just the photos above, and see how we discovered the heads contaminants, here is the video.

I just watched your video. Unbelievable! Please start a new thread with the video attached. This info needs to get out there. Thanks

Folks need to know, I'll do as you suggest.I just watched your video. Unbelievable! Please start a new thread with the video attached. This info needs to get out there. Thanks

Thanks. Yes they need to know.Folks need to know, I'll do as you suggest.

Besides the distraction of what we found...

We do believe these heads are going to fit our build perfectly and help us meet our goals from the 5.2. We'll show any touch ups that we do to them and the completed heads

We do believe these heads are going to fit our build perfectly and help us meet our goals from the 5.2. We'll show any touch ups that we do to them and the completed heads

Scrub-a-dub dub, with a toothbrush in a cleaning vat tub!

Moparofficial has a good video on youtube about these heads and some mods to help them.Besides the distraction of what we found...

We do believe these heads are going to fit our build perfectly and help us meet our goals from the 5.2. We'll show any touch ups that we do to them and the completed heads

At a minimum I would do a chamber relief between the intake valve and edge of the chamber, and make sure there isn't a lip above the valve job to hurt flow. 15 degree top angle cut on the valve job would likely help both issues.

Wouldn't cost much to do a back cut on the intake valves while you have the heads

apart to clean them.

Last edited:

Normally I would do my home touch up - inspection to the heads and move forward without batting an eye. However, just for the viewer, I'm thinking on taking these to the machinist to get a "professional" opinion on the valve job, valve guides, and stem heights. This will give a "higher qualified" opinion on the quality of the machine work on the heads. I plan to "touch up" some edges I don't like with my dremel.

Been a bit, but today we cleaned the decks on the block, removed the cam, lifters, and distributor intermediate shaft. The lifters fought us like a wisdom tooth in a horse. Cam had a couple of lobes with "metal missing". Nothing showed on the rollers. Overall, it looks good to this point. Onward .......

P.S. - I don't have pictures, but the video is up on my youtube channel.

P.S. - I don't have pictures, but the video is up on my youtube channel.

j par

Well-hung Member

P.S. - I don't have pictures, but the video is up on my youtube channel.

Oh, I also measured the how far the pistons were down the hole. I got .042 and I only checked one.

j par

Well-hung Member

You can round that off to a half inch....Oh, I also measured the how far the pistons were down the hole. I got .042 and I only checked one.

I missed it ......You can round that off to a half inch....

??

??Mopar44134

Well-Known Member

@318willrun two questions

Can the cam be used as a core, to be reground?

Are you going to reuse the lifters? After seeing the cam, im surprised they showed no signs of damage.

Can the cam be used as a core, to be reground?

Are you going to reuse the lifters? After seeing the cam, im surprised they showed no signs of damage.

Maybe on the cam, but I wouldn't start with it. Seems that is not all that uncommon on the magnums. Maybe the factory just let it go means it a roller. Lifters I'll have to clean and inspect. I have other lifters if I cannot use them.@318willrun two questions

Can the cam be used as a core, to be reground?

Are you going to reuse the lifters? After seeing the cam, im surprised they showed no signs of damage.

How were the cam bearings? I have a cam to swap into my 150k? 5.9 that’s in my Duster. Sure hope the bearings still look good in it, as I plan to just swap the cam and heads in the car.

cam bearings showed wear, but looked better than I thought they would. Seems the magnums will eat at least one cam bearing. Haven't decided if I'll use them or not, I'll have to look closer.How were the cam bearings? I have a cam to swap into my 150k? 5.9 that’s in my Duster. Sure hope the bearings still look good in it, as I plan to just swap the cam and heads in the car.

-