1wild&crazyguy

Banned

There are folks who would like to get started on porting heads themselves along with those who might be curious as to what this or that will yield 'cfm wise'.... This thread is for them.

So it go's without saying that most of the time when the question of.. ''can i port my own heads?'' comes up ..most responses are.. ''just smooth the angles in the bowl and call it good'' ...well, i will do just that and then some as the thread go's on, so stay tuned...

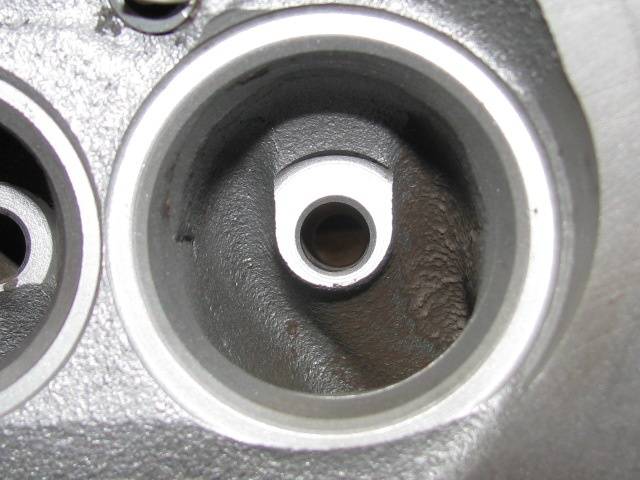

1st up is a regular old 675 casting 1.78/1.50 head that i flowed as cast 'intakes for now' and then with nothing but the ''smoothed/rounded angles approach'' so we can see what actual improvement there may be.

*I had numbers from another int port on this head, but to keep it real..i started fresh and flowed the actual port that im working on*

as cast cfm@lift

.100--46

.200--108.6

.300--158

.400--169

.500--171

.550--173

.600--175

-------176\/

So it go's without saying that most of the time when the question of.. ''can i port my own heads?'' comes up ..most responses are.. ''just smooth the angles in the bowl and call it good'' ...well, i will do just that and then some as the thread go's on, so stay tuned...

1st up is a regular old 675 casting 1.78/1.50 head that i flowed as cast 'intakes for now' and then with nothing but the ''smoothed/rounded angles approach'' so we can see what actual improvement there may be.

*I had numbers from another int port on this head, but to keep it real..i started fresh and flowed the actual port that im working on*

as cast cfm@lift

.100--46

.200--108.6

.300--158

.400--169

.500--171

.550--173

.600--175

-------176\/

Last edited by a moderator: