You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

340 TA Heads....

- Thread starter Woodie

- Start date

-

72Dart6pack

Harder Better Faster Stronger.

They flow horrible. Quick. Sell them to me & cut your losses. Lol

pishta

I know I'm right....

No better than 340/360 heads, because they are the same....

They flow horrible. Quick. Sell them to me & cut your losses. Lol

You silly guy! Lol

replicaracer43

Grumpy Old Man

- Joined

- Oct 10, 2008

- Messages

- 6,051

- Reaction score

- 7,867

Exactly the same as any 2:02 J head, you could sell them for enough to put a much better head on your engine.

They look like they have been gasket matched. Along with them I picked up a Port-O-Sonic Iffy.No better than 340/360 heads, because they are the same....

I just might post them up on the E body site.Exactly the same as any 2:02 J head, you could sell them for enough to put a much better head on your engine.

pishta

I know I'm right....

port-o-sonic is a great intake too. nice score. Flip them to a T/A guy and buy some AL Commandos.

replicaracer43

Grumpy Old Man

- Joined

- Oct 10, 2008

- Messages

- 6,051

- Reaction score

- 7,867

Using a solid roller cam might require some machine work on the heads also, for the required springs.

Alaskan_TA

Well-Known Member

The heads are easier to find than a full set of rockers so they by themselves are typically worth more than the heads.

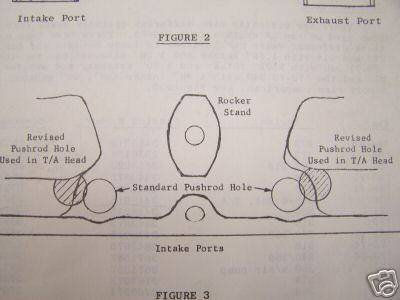

The magic of these heads happens when you port them out. The moved pushrod hole is the key.

pishta

I know I'm right....

you can make any 340 head a T/A design, just fill the original pushrod hole and drill a new one. Its the rockers that are T/A, then you can port the bejeezers out the intake.

If I knew back in 1986 that the T/A heads I bought (without rockers) were no better than the stock 2.02's my 340 came with I wouldn't have spent 3 days trying to get W2 rockers to work, we did it in the end but the car ran no quicker and it wasn't 100% successful.

port-o-sonic is a great intake too. nice score. Flip them to a T/A guy and buy some AL Commandos.

The magic of these heads happens when you port them out. The moved pushrod hole is the key.

Crappy pic... Hard to tell if the port is stock. They look to be cleaned up, they fit a Felpro gasket like a glove.

Last edited:

Locomotion

Well-Known Member

Note that the casting number is the same as early 360 heads - 915. Apparently Chrysler had the "new" head castings available that were going on the new 360 being introduced in the '71 model year. (360 blocks started to be cast in 1970.) So they machined the raw head castings for the respective applications - 340-6. 340-4 and 360-2. (i.e.: pushrod location and valve size) The rest of the casting, including ports, remained the same.

To me it looks like the chambers may have been polished a bit too, and valves look like aftermarket stainless. Probably "nail-head", which is better for the intakes than OEM "tulip" style.

To me it looks like the chambers may have been polished a bit too, and valves look like aftermarket stainless. Probably "nail-head", which is better for the intakes than OEM "tulip" style.

Last edited:

Thanks for the input.Note that the casting number is the same as early 360 heads - 915. Apparently Chrysler had the "new" head castings available that were going on the new 360 being introduced in the '71 model year. (360 blocks started to be cast in 1970.) So they machined the raw head castings for the respective applications - 340-6. 340-4 and 360-2. (i.e.: pushrod location and valve size) The rest of the casting, including ports, remained the same.

To me it looks like the chambers may have been polished a bit too, and valves look like aftermarket stainless. Probably "nail-head", which is better for the intakes than OEM "tulip" style.

the port o sonic is not a great intake it is fair at best .

port-o-sonic is a great intake too. nice score. Flip them to a T/A guy and buy some AL Commandos.

Marcohotrod

Well-Known Member

the 3418915 head was used on 1970 340, 1970 340 six, 1971 340 and 1971 360. stock on a six it was the same size intake port as a four barrel, but with the pushrod passage moved over, the intake ports could be ground wider for about 10% more flow. back in the day the upgrade of intake was the ld340, then the portosonic, then the victor

Marcohotrod

Well-Known Member

more pushrod bump can be ground out, for a little more flowCrappy pic... Hard to tell if the port is stock. They look to be cleaned up, they fit a Felpro gasket like a glove.

View attachment 1715178388

Marcohotrod

Well-Known Member

how do u suggest to "just fill the pushrod hole and drill a new one" in my backyard?you can make any 340 head a T/A design, just fill the original pushrod hole and drill a new one. Its the rockers that are T/A, then you can port the bejeezers out the intake.

Locomotion

Well-Known Member

Not sure how the Port-O-Sonic compared to the others when using a Holley carb, but it was suppose to be better than the LD340 in Super Stock when the "popsicle stick" mod was used to help fuel distribution with a Thermoquad. The Holley Strip Dominator superseded that when it was introduced.

While it's not a "backyard" project, machining the original pushrod holes to allow a press-fit of a metal slug and redrilling them to the T/A location was the usual procedure. Using a metal slug that was a different color/shade would help you see where you were in the porting process.

While it's not a "backyard" project, machining the original pushrod holes to allow a press-fit of a metal slug and redrilling them to the T/A location was the usual procedure. Using a metal slug that was a different color/shade would help you see where you were in the porting process.

pishta

I know I'm right....

At home? Your brave! Put some automotive epoxy on a 2.5 x .500 steel rod and drive it in. Use a grinder to even everything out if it if it matters to you as its under the valve cover anyway. Get your best 1/2 inch carbide drill and drill the new hole using measurements . Start porting your intake and when you get close to breaking through the original hole, your iron will turn 50 shades of blue. if you keep going you'll just start grinding into the metal rod, no harm as its a permanent part of the head now. Now all of this can be done at a machine shop too. Loco beat me too it.

Last edited:

Not according to the MP book!the port o sonic is not a great intake it is fair at best .

Also do realize that is also from the point of view of “Racing” and not on the street.

for racing the victor beats it hands down . on the street the offy performs good for a single plane . we found the offy did well up to 6000 or a little more but the victor would pull to 7000 easily .

jmo.

jmo.

-