RAMM

Well-Known Member

Yes I know it's not exactly a small block or a Gen 1 354 but it is a Mopar and it does make some decent power.

2005 5.7 Block 3.947" bore x 3.625" stroke (offset ground 6.1L crank HRJ)

Arrow 6.200" .866" 1.89" Honda Rod Journal Piston guided

Custom JE domed slugs Comp 11-1 .043"/043" 3 mm TS AP rings

ARP studs/Head Bolts

Custom Cam .630" 111 LSA 240's @ .050"

Early 5.7 Heads with 6.1 intake port/filled floors (300 cfm @ .500-.600")

Manley 2.04"/1.57"

Cascar intake

Holley XP 650 dbl

MSD HEMI programmable timing

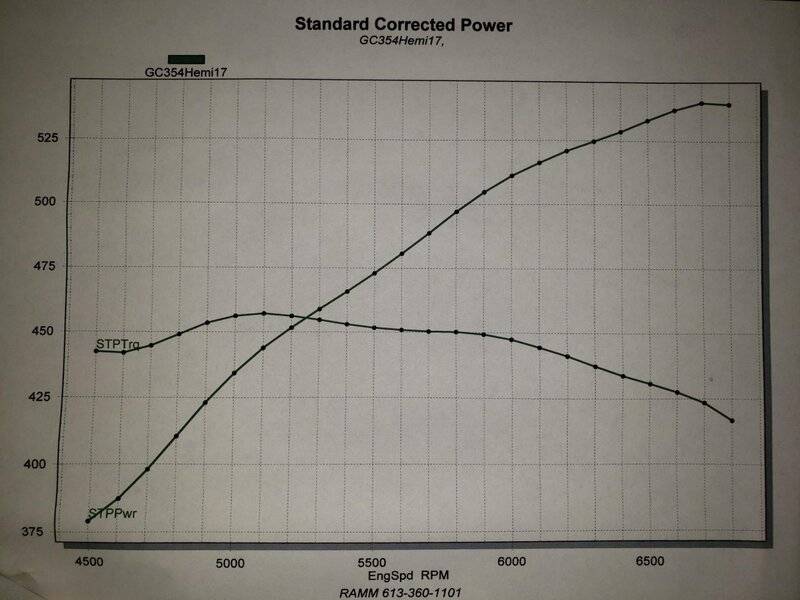

Made 542hp @ 6900-7000 457 tq @ 5100 rpm with the Jone Racing setup and small PaceSetter headers for a 300C. Pretty decent small cube build I think. It's going in a 70 Cuda with a 4spd--should be fun. J.Rob

p.s. Mods feel free to move this thread to wherever it belongs.

2005 5.7 Block 3.947" bore x 3.625" stroke (offset ground 6.1L crank HRJ)

Arrow 6.200" .866" 1.89" Honda Rod Journal Piston guided

Custom JE domed slugs Comp 11-1 .043"/043" 3 mm TS AP rings

ARP studs/Head Bolts

Custom Cam .630" 111 LSA 240's @ .050"

Early 5.7 Heads with 6.1 intake port/filled floors (300 cfm @ .500-.600")

Manley 2.04"/1.57"

Cascar intake

Holley XP 650 dbl

MSD HEMI programmable timing

Made 542hp @ 6900-7000 457 tq @ 5100 rpm with the Jone Racing setup and small PaceSetter headers for a 300C. Pretty decent small cube build I think. It's going in a 70 Cuda with a 4spd--should be fun. J.Rob

p.s. Mods feel free to move this thread to wherever it belongs.