Babyblue66

Cool dude

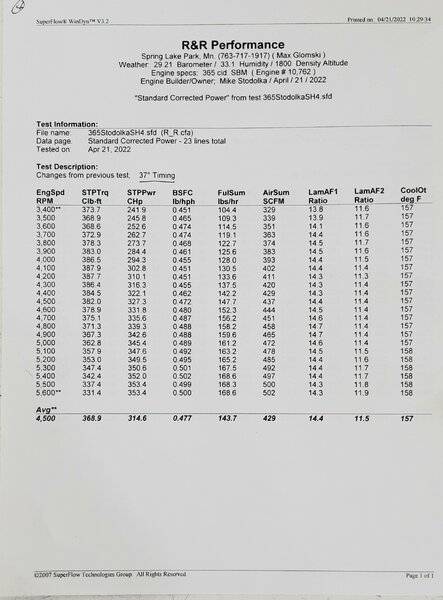

I built this for a lady's 71 Duster. Her old 360 was a turd. She also requested it "sounds good".

8.8 to 1 using speed pro H405CP pistons

2.02 1.60 stainless valves

Stock replacement rockers, shafts, and pushrods

J heads with a little pocket porting

Hughes 2336 Whiplash cam

Performer intake

Recurved old Mopar Performance distributor

Milodon windage tray

9 keyway timing chain degreed per cam card

With my 750 Holley HP it made

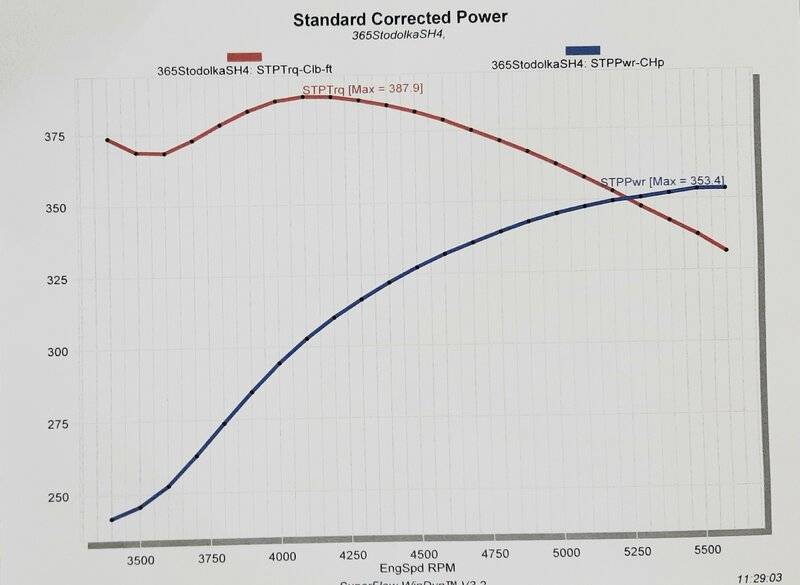

353 hp

388 ft lbs

Using her 600 Edelbrock it lost about 10hp and torque.

Ignore that little curve at the beginning of the pull. It has something to do with loading the dyno.

8.8 to 1 using speed pro H405CP pistons

2.02 1.60 stainless valves

Stock replacement rockers, shafts, and pushrods

J heads with a little pocket porting

Hughes 2336 Whiplash cam

Performer intake

Recurved old Mopar Performance distributor

Milodon windage tray

9 keyway timing chain degreed per cam card

With my 750 Holley HP it made

353 hp

388 ft lbs

Using her 600 Edelbrock it lost about 10hp and torque.

Ignore that little curve at the beginning of the pull. It has something to do with loading the dyno.

Last edited: