2 Darts

A-body Addicted

I know there are mostly ¼ mile junkies here. There was a time when MOPAR was interested in lap times, too. I am thinking of something that might be raced today. Kind of stops thoughts of the NASCAR attempt that was so owned by hyper-pack Valiants in 1960 & 1961 that the series was dropped.

Back in 65 and 66 there was Team Starfish running Barracudas and Group 44 running Darts in the A/Sedan class of the SCCA on the amateur level, called TransAm for the pros. I am interested in running a MOPAR in the SRVA. Unfortunately the only engine available back in 65 & 66 was the trusty rusty 273. The cars are allowed a 5 liter engine without penalty. The 318 block can be used, but it carries a weight penalty. I might be able to make a case for running a 340 block, however coming up with a Keith Black crank to bring it down to 305 CID is going to be cost prohibitive if not impossible. *

I have read the rules for the class. I have posted a link so you can too. Barracuda / Valiant / Dodge Dart (64-66)

However, a 273 cut .030 over and fitted with a 360 small journal crankshaft yields 301.xx cubic inches. Very much allowed by the rules. I have a few ideas about how to outfit the engine beyond just getting to the 301 CID mark. To be competitive, the engine needs at least 450 hp at the crank, on a single 4 barrel carburetor. I will assume an operating range of 3000-8000 rpm **. Cylinder heads can be any year and roller cams are possible, as is dry sump lubrication piggy-backed on a wet sump.

I'd like to see what the collected wisdom of FABO has to offer as suggestions on building a MOPAR to specs.

Questions I have are:

Has anyone established a go-to person for finding solid 273 blocks?

Are high compression pistons available in the after market? Forded or cast?

Is the piston speed going to be a limiting factor on how tight the engine can be run?

Can 1.88/1.60 valves be installed on 308 heads with some machine work, of course?

Is there enough meat on the cylinder heads to let the seats for the 1.88/1.60 valves be installed on the engine?

Can the RHS/Indy heads be used without notching the block?

Magnum cylinder heads?

Intake can be aluminum, so should it be dual or single plane? Recommendations?

Thinking of using an an Accusump along with a Windage tray (for the 360) and a road race oil pan?

DUI or Mopar electronic distribiutor?

What kind of headers would you install and route through the left side notch in the cross member into a NASCAR type of outlet?

Notes:

* Keith Black was the prime contractor for the factory AAR and TransAM cars MOPAR teams fielded in the 1970 season. I read somewhere that depleted uranium was used in the crankshaft counterweights.

** Boss 302 Mustangs will turn up to 9000 rpm routinely. I don't think piston speed will let that happen with a 3.58 crank stroke.

It is kind of late. But I will leave with a few visions dancing in my head.

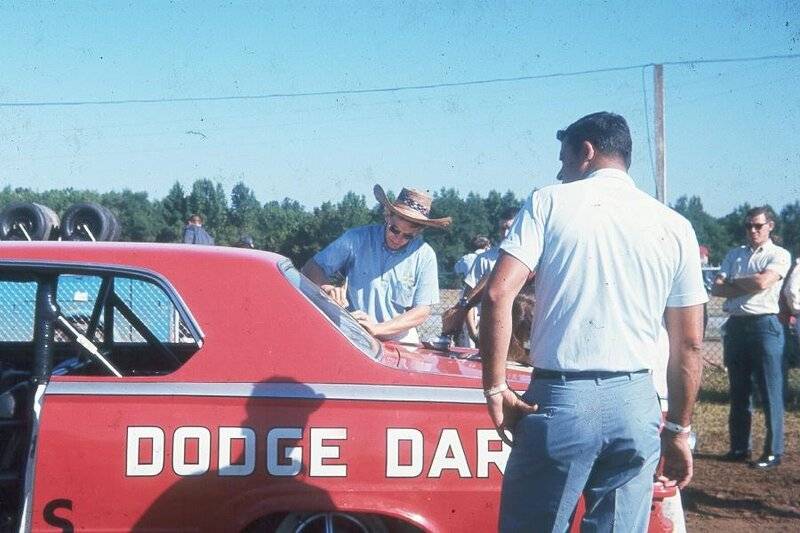

The fellow with his back to the camera was the driver of this car. Do you know who he is?

The fellow with his back to the camera was the driver of this car. Do you know who he is?

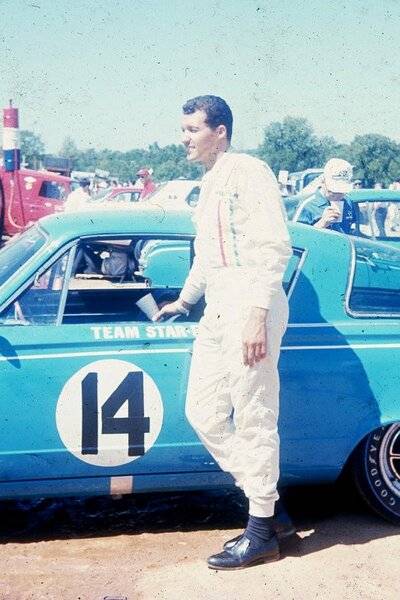

Recognize this fellow?

Back in 65 and 66 there was Team Starfish running Barracudas and Group 44 running Darts in the A/Sedan class of the SCCA on the amateur level, called TransAm for the pros. I am interested in running a MOPAR in the SRVA. Unfortunately the only engine available back in 65 & 66 was the trusty rusty 273. The cars are allowed a 5 liter engine without penalty. The 318 block can be used, but it carries a weight penalty. I might be able to make a case for running a 340 block, however coming up with a Keith Black crank to bring it down to 305 CID is going to be cost prohibitive if not impossible. *

I have read the rules for the class. I have posted a link so you can too. Barracuda / Valiant / Dodge Dart (64-66)

However, a 273 cut .030 over and fitted with a 360 small journal crankshaft yields 301.xx cubic inches. Very much allowed by the rules. I have a few ideas about how to outfit the engine beyond just getting to the 301 CID mark. To be competitive, the engine needs at least 450 hp at the crank, on a single 4 barrel carburetor. I will assume an operating range of 3000-8000 rpm **. Cylinder heads can be any year and roller cams are possible, as is dry sump lubrication piggy-backed on a wet sump.

I'd like to see what the collected wisdom of FABO has to offer as suggestions on building a MOPAR to specs.

Questions I have are:

Has anyone established a go-to person for finding solid 273 blocks?

Are high compression pistons available in the after market? Forded or cast?

Is the piston speed going to be a limiting factor on how tight the engine can be run?

Can 1.88/1.60 valves be installed on 308 heads with some machine work, of course?

Is there enough meat on the cylinder heads to let the seats for the 1.88/1.60 valves be installed on the engine?

Can the RHS/Indy heads be used without notching the block?

Magnum cylinder heads?

Intake can be aluminum, so should it be dual or single plane? Recommendations?

Thinking of using an an Accusump along with a Windage tray (for the 360) and a road race oil pan?

DUI or Mopar electronic distribiutor?

What kind of headers would you install and route through the left side notch in the cross member into a NASCAR type of outlet?

Notes:

* Keith Black was the prime contractor for the factory AAR and TransAM cars MOPAR teams fielded in the 1970 season. I read somewhere that depleted uranium was used in the crankshaft counterweights.

** Boss 302 Mustangs will turn up to 9000 rpm routinely. I don't think piston speed will let that happen with a 3.58 crank stroke.

It is kind of late. But I will leave with a few visions dancing in my head.

Recognize this fellow?

Last edited: