Minnesota Muscle

Well-Known Member

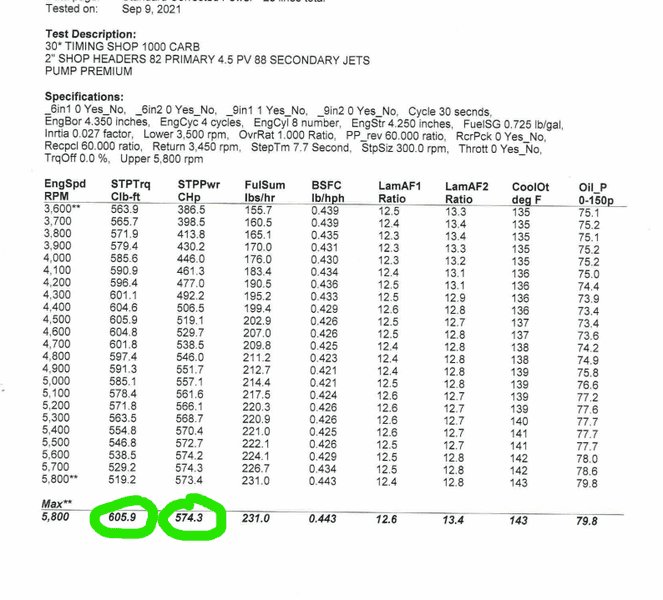

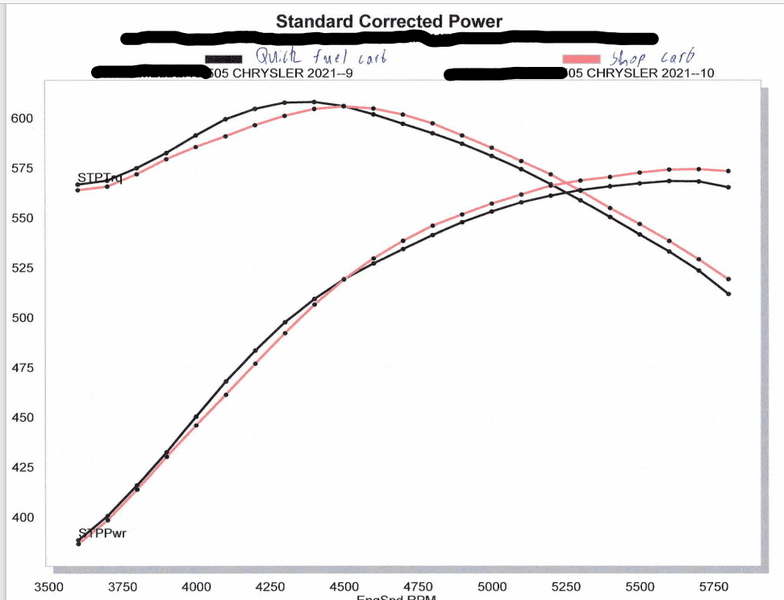

So there's the question. This is the first stroker build for me. After comparing notes with very similar builds it seems to be missing 50-75 horse easy. Even the owner of the engine shop/dyno felt it was lacking greatly. It fired right up and break-in was flawless, runs smooth after ten pulls this dyno sheet below was the best we could do, and that's with their 1000cfm carb and a 2" spacer. 574hp and 605tq is all it had. Changing from the 950 quickfuel to their 1000 holley gained it only a couple HP difference, hardly noticeable. Engine liked 30deg of timing the best. At 32deg, it lost 4hp and 2tq and kept loosing power with any increase in timing. This is a very reputable shop that does many big HP engines, so I trust their equipment. The shop owner could only speculate that I was somehow given the wrong pistons and have something like 9:0.1 compression, which is a piston 440 source offers as an option. I will be calling 440 source on Monday to see if there was any chance this could be the case.

-1978 440 block bored .30 over

Lined honed and deck just cleaned up. Bearing clearance at .00275-.003

-440 source 512 stroker kit with 78cc pistons for a com ratio of 10.6:1

- 440 source stud girdle

- ARP studs on mains and everywhere else in engine

-Untouched Trickflow 240 heads

- .040 MLS head gasket

-Cam is a custom grind Howards Solid FT

Lift .599in .620ex 110 lobe sep

Duration @ .50 254/262

Lash set to .016 cold as it calls for .018 hot

-Rocker arms are PRW 1.5 ratio steel roller with B3 racing spacers for correct geometry which caused me to loose about .025 lift which puts me closer to .574in / .595ex

-Smith Bros 3/8" dia push rods

-Headers 2"

-Victor intake

-Carb Quickfuel 950

-All MSD ignition

-6qt pam

-Melling high volume pump

-Brad Pen 30weight break in oil

-1978 440 block bored .30 over

Lined honed and deck just cleaned up. Bearing clearance at .00275-.003

-440 source 512 stroker kit with 78cc pistons for a com ratio of 10.6:1

- 440 source stud girdle

- ARP studs on mains and everywhere else in engine

-Untouched Trickflow 240 heads

- .040 MLS head gasket

-Cam is a custom grind Howards Solid FT

Lift .599in .620ex 110 lobe sep

Duration @ .50 254/262

Lash set to .016 cold as it calls for .018 hot

-Rocker arms are PRW 1.5 ratio steel roller with B3 racing spacers for correct geometry which caused me to loose about .025 lift which puts me closer to .574in / .595ex

-Smith Bros 3/8" dia push rods

-Headers 2"

-Victor intake

-Carb Quickfuel 950

-All MSD ignition

-6qt pam

-Melling high volume pump

-Brad Pen 30weight break in oil

Last edited: