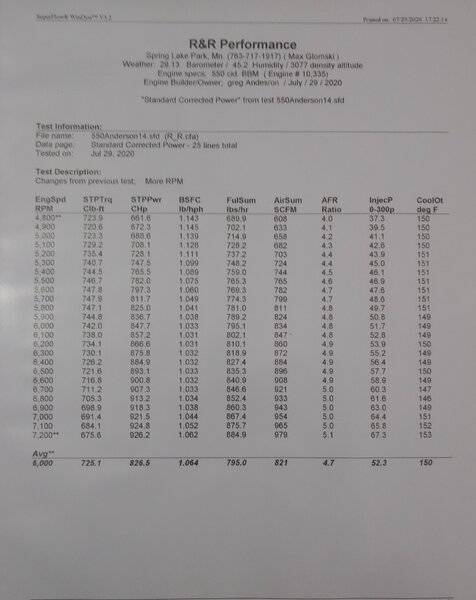

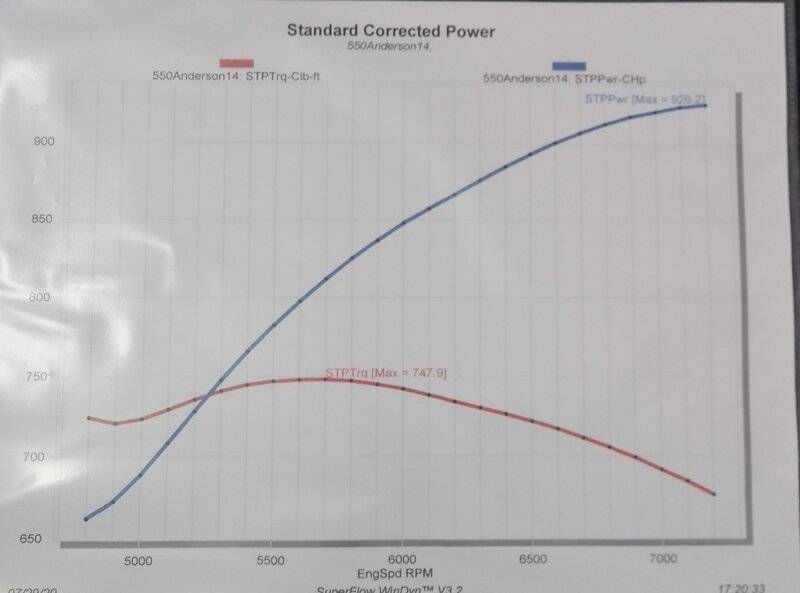

I finally got my race motor dyno'd.

4.5043 bore. 4.315 stroke. 2.2 rod bearings 6.86 molner h beams, CP pistons coated by line 2line to make up the overbore of .0043 from 4.5000. Megablock. Charlies SS style pan. Cam is a Jones Cams inverted flank roller with 284/296/114 @ .050 duration. .510 intake lobes .480 exhaust lobes. 1.7 Jesel rockers for .867 intake lift and .816 exhaust lift. .019 in lash .020 ex lash. 15.0 compression.

Heads are 440-1 fully ported with 2.30 intakes, 1.78 exhausts. Heads flow 390 at .900 on the intakes. 3x Indy intake manifold. Rons Terminater alcohol injection , methanol fuel. Headers are 2 1/8 x 30 x4 inch collecters. Dyno headers were 2 1/4 tubes. I was hoping for 880 to 900. So i am pretty happy! We tested with my aircleaner, lost 4 hp. My race 2 1/8 headers lost 1 hp! So the motor should be within 5 hp of dyno numbers in the dart.

4.5043 bore. 4.315 stroke. 2.2 rod bearings 6.86 molner h beams, CP pistons coated by line 2line to make up the overbore of .0043 from 4.5000. Megablock. Charlies SS style pan. Cam is a Jones Cams inverted flank roller with 284/296/114 @ .050 duration. .510 intake lobes .480 exhaust lobes. 1.7 Jesel rockers for .867 intake lift and .816 exhaust lift. .019 in lash .020 ex lash. 15.0 compression.

Heads are 440-1 fully ported with 2.30 intakes, 1.78 exhausts. Heads flow 390 at .900 on the intakes. 3x Indy intake manifold. Rons Terminater alcohol injection , methanol fuel. Headers are 2 1/8 x 30 x4 inch collecters. Dyno headers were 2 1/4 tubes. I was hoping for 880 to 900. So i am pretty happy! We tested with my aircleaner, lost 4 hp. My race 2 1/8 headers lost 1 hp! So the motor should be within 5 hp of dyno numbers in the dart.