Picked up a 99 explorer rear for $75.00. It has disk brakes and 3.27 gear/open diff. The 3.27 would be just right for my car with the specs seen in my signature. I'm trying to do this on the cheap. I will drill out the 3 slug welds then use a hydraulic ram to press out the driver side tube. Cut off the 27/8" from the end and press it back in. Weld the tubes to the housing and be done. I seen these trick spring perches that im willing to try so that I can center my axle under the car and set pinion angle. I would like to add new EPSO HD springs and the 1/2" offset shackles from doctor diff to complement the install. Not sure how long this will take me and I know this has been done plenty of times. However, Ill do my best to document it as I go along.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

67 Fastback getting 8.8 rear

- Thread starter 67/6barracuda

- Start date

-

Best of luck...Those spring hanger " loops", are interesting....

Princess Valiant

A.K.A. Rainy Day Auto

I am watching this ...planning to do the same in my valiant.

just cant see spending a thousand dollars for a rear when there are plenty of capable ones at the pick a part for my slant six car.

just cant see spending a thousand dollars for a rear when there are plenty of capable ones at the pick a part for my slant six car.

Jlcaptain24

Well-Known Member

8.8 with 3.27 gears w/traction lock behind my 440 dart. You won't regret the swap!!

Tinbasher

Well-Known Member

Hi curious as to your source for the novel spring perches ? Seems it would prevent

warping the housing from welding If they don't rotate, but a short weld

should solve any problem I would guess

warping the housing from welding If they don't rotate, but a short weld

should solve any problem I would guess

TINBASHER,Hi curious as to your source for the novel spring perches ? Seems it would prevent

warping the housing from welding If they don't rotate, but a short weld

should solve any problem I would guess

Sorry for the late response both Summit and Speedway have them. However, im not going to use them because the 8.8 rear is 3.25"dia not 3"...probably wont fit. Ill just use the cheaper standard size 3.25dia ones off ebay.

Folks,TINBASHER,

Sorry for the late response both Summit and Speedway have them. However, im not going to use them because the 8.8 rear is 3.25"dia not 3"...probably wont fit. Ill just use the cheaper standard size 3.25dia ones off ebay.

View attachment 1715087591

View attachment 1715087593

I made a little bit of progress. I drilled out the 3 plug welds which is a complete pain in the *** mainly because I could not for the life of me find the right metal bits. Started with a 1/16th pilot and worked up to a 5/8" bit which i finally found at TSC. I was was dead on lined up with the first plug. The other 2 plugs not so much.

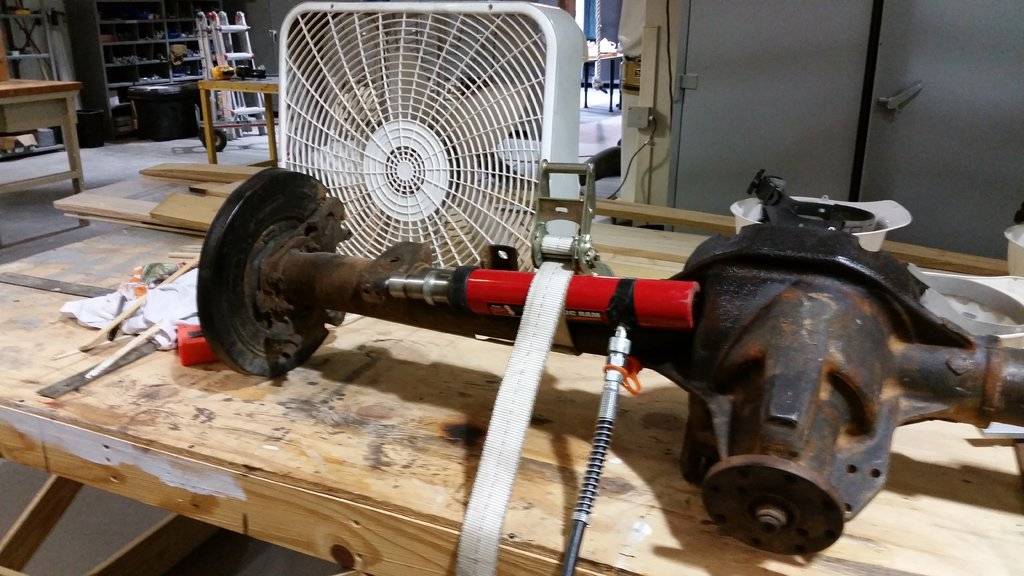

The second course of action was making a couple reference marks on the axle tube. I scribed a line on the tube right next to the housing. This will let me know how far the tube was pressed in originally. The second reference line will be used to keep the correct orientation of the tube as it is being pressed back in. You can't see the reference marks in the photos but hopefully you get what i mean. I then used my coworkers hydraulic ram. Which i believe he said he got at harbor freight for like 30.00 bucks. I ratchet strapped it down and it pressed it out nice and easy. You can see in the picture I have it in between the spring perch and the housing. I was a little scared of braking the housing or bending the axle tube but it punched it out no problem. Tomorrow Ill make my cut on the tube and take it from there.

I completed cutting 27/8" off the drivers side axle tube with a jet band saw. Then beveled the edge a little with a angle grinder to help when pressing it back in.

I received my Dr. Diff 1/2" offset Shackles and spring perches as well. They seem to be quality pieces with black powder coating. I opted for the 5/8" bolts over the 1/2" bolts. When I order my springs from EPSO ill order the larger 5/8" bushing. You can see in the photo how the Dr. Diff bolt heads are beveled and the brackets are recessed. There is no need to drill a hole in the frame rail like most brands.

Last edited:

That's where it's going to get interesting. I'm going to build a wooden jig for the axle housing and tube to sit in. Then place everything in between two heavy trucks. Using the trucks as back stops I'm going to use a 20ton bottle jack turn it side ways up against the two trucks and press the tube in. I'll be sure to take pictures.Curious about the method you will use to press the axle tube back in

I went a different route pressing the tube back in using a 20ton bottle jack. I placed everything in a bobcat bucket and pressed it in. It kept lifting up on me as I applied pressure. The fix was to wedge the wood blocks between the bucket top, bottom, left and right. It took a lot of time resetting the jack as it only pressed about a 16th at a time then readjusting while adding more blocking. May look crazy but it worked.

hoosierdaddy

Well-Known Member

Now thats real car guy **** . I love it when you have to get creative .

Now thats real car guy **** . I love it when you have to get creative .

Made a little progress. A friend helped stick weld with -5* down on the pinion angle. Its probably wrong but I had to pick a number and go with it. I may have to shim it later. I didn't do the preferred method of getting it under the car and adjusting the pinion angle like I wanted to. The welding was a free limited resource, so I had to take advantage of the situation and get it done. Plan is to weld the axle tube to the housing as well. Possibly have it all done tomorrow. So far so good spring perches set at 42"O.C. for my DocDiff offset shackles.

Guys its been long enough I gotta get motivated. I was able to remove my rear 7.25 and springs. I tell you doing it all laying on the concrete builds some character for sure.

all new brake hardware probably has less than 500 miles on it what a waste. Problem is I can't leave well enough alone.

Last edited:

Whats interesting is the stock 7.25" spring perches are set at positive 7 degrees. Measured by leveling the perch and putting the angle finder on the pinion flange. I mounted my perches on the 8.8 at 5 degrees negative so im way off ill have to cut them off. My trans angle is 2 degrees negative so ill weld the new perches probably 2 degrees positive to parallel the drive-line angles.

A comparison of the Moroso's part#85090 and the DoctorDiff's perches. The Moroso's have the correct 1/2" locator pin hole. The Doctordiff's are 5/8" also 1/4" taller. I wasted money on 3 sets of perches but the Moroso's are the the ones Ill weld back on. View attachment 1715125661 View attachment 1715125662

Last edited:

Cut off the spring perches for the second time and ground everything smooth again. Also, cut off the ears of the reluctor wheel sensor just because they're goofy.

Another member had a great idea of cutting off the tab that connects on the fords emergency brake cable and welding them onto the original Mopar brake cables. This is the route im going, but i also cut off the original Mopar return spring to use the bigger and correct length ford spring for the return. I will have to drill the the opening just a tad on the ford housing bracket in order for the Mopar cables to fit right.

Grnwinger

Active Member

Nice to see a welder grounding as close as possible to the weld

Got the the Plymouth e-brake cables fitted to the Ford e-brakes today. Laura from Springs&Things should be sending out my +1 6 leafs this week, I can't wait.

Final fit and finish of the e-Brake cable. I had to cut about and inch off the spring to prevent over binding. I think this will serve its purpose. I plan to abuse my car from time to time. l will see how it holds up when I pull the e-brake to flip her around then come out of it burning the tires off.

-