Stoked to hear that. Most of my big track stuff has all been motorcycles. We have lots of options in so.cal. Have been getting more into Kart racing past few years. However, with a son who is faster than me.. we may be in a Miata pretty soon to play at the real tracks. You are familiar with the Green Brick Valiant?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

69 Dart 340 Swinger Street/Road Race build

- Thread starter black954

- Start date

-

black954

Well-Known Member

Man, that sounds awesome to be able to race with your son. My son races motocross and is only 9, but has just about surpassed my lap times lol. I envy you’re weather and track situation for sure. Those Miatas are easily turned into track weapons so that would be a great next step. I’m going to set up one of my sons bikes as a supermoto to get him started into road courses. I road raced a lot of different sport bikes and supermoto so it would be cool to get him into that.Stoked to hear that. Most of my big track stuff has all been motorcycles. We have lots of options in so.cal. Have been getting more into Kart racing past few years. However, with a son who is faster than me.. we may be in a Miata pretty soon to play at the real tracks. You are familiar with the Green Brick Valiant?

abdywgn

dismantler

let us know when you go so we can cheer you on!

black954

Well-Known Member

A little progress on the drivetrain. I picked up the trans and a bunch of other related parts from my dads house so I could degrease and power wash them. Then I was able to bead blast the timing cover and get some parts painted. I’ve been cleaning a lot of hardware and small parts lately so they’re all ready to go when the engine goes back together.

Monday I should be able to drop the flywheel and balancer off at the machine shop so they can balance the rotating assembly. I’m crossing my fingers that I should be able to assemble the bottom end by the end of next week.

Monday I should be able to drop the flywheel and balancer off at the machine shop so they can balance the rotating assembly. I’m crossing my fingers that I should be able to assemble the bottom end by the end of next week.

black954

Well-Known Member

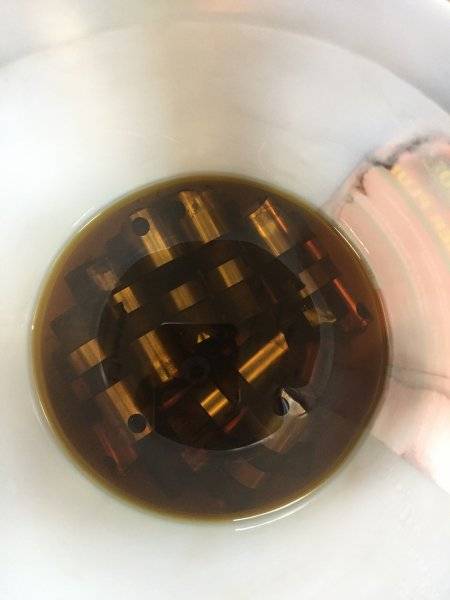

It’s a heated ultrasonic cleaning tank. If it’s all steel parts, I use 5 gallons of water and about a quart of Purple Power degreaser. If there’s aluminum parts, I use a special ultrasonic cleaner solvent by Two2Cool at a much lower ratio. I have some locking stainless mesh baskets I put small parts in so I don’t lose them. It works good, but if the parts have heavy grease you still have to brush them off after they’ve gone through a 90min cycle.

black954

Well-Known Member

Few parts painted

black954

Well-Known Member

This morning I removed the heater box to see how the core looked. I was greeted with a mouse nest and a corroded original brass core lol. Luckily there’s a shop near me that still recores radiators and heater cores so I dropped it off to have them recore it. Then I ordered all the seals and clips from Detroit Speed to recondition the heater box. I think my blower motor will be fine to reuse. It spins very freely and seems to be in good shape.

My flywheel from American Powertrain showed up so I was able to bring it with the harmonic balancer to the machine shop so they can finally balance my rotating assembly. He said it should be ready to pick up tomorrow, so I might actually be able to assemble the short block this week. Also, my intake shipped on Saturday so I should have that this week and I’m crossing my fingers IMM ships my heads today.

Lastly, I ordered a black cut pile carpet kit with mass backing from ACC on Friday. I also ordered a vehicle wiring harness from Ron Francis. Both should ship out in 2 weeks or so.

My flywheel from American Powertrain showed up so I was able to bring it with the harmonic balancer to the machine shop so they can finally balance my rotating assembly. He said it should be ready to pick up tomorrow, so I might actually be able to assemble the short block this week. Also, my intake shipped on Saturday so I should have that this week and I’m crossing my fingers IMM ships my heads today.

Lastly, I ordered a black cut pile carpet kit with mass backing from ACC on Friday. I also ordered a vehicle wiring harness from Ron Francis. Both should ship out in 2 weeks or so.

black954

Well-Known Member

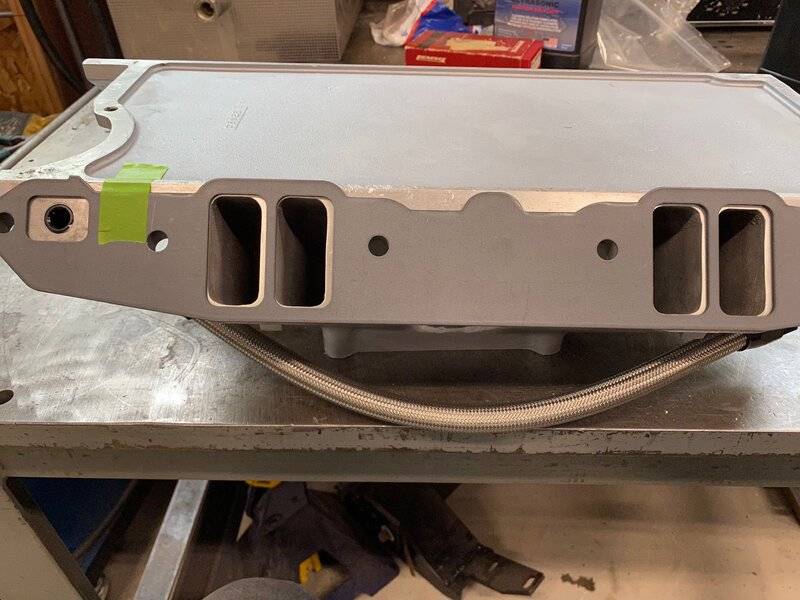

Small update. I scrubbed and cleaned the heater box. There was still a hint of mouse piss, so I painted the areas the nest was in with oil based paint. So far, no more smell. Then I cleaned all the roller lifters so they’re ready to go. Also, my M1 intake showed up this morning. I’m overly happy with the condition of it. I was figuring I’d have to bead blast it and seal or paint it, but it’s so nice, I’ll lightly clean it and run it as is. Just waiting on the machine shop now......

black954

Well-Known Member

Got some good news from the machine shop so I went and picked up my parts this afternoon. I was feeling ambitious so after dinner I was able to file fit the rings, check bearing clearances, and assembled the rotating assembly.

black954

Well-Known Member

Can you guess what I’m still waiting on?!?!?

The waiting is the hardest part. I can't believe how much youve got done in just a few month. Impressive.

black954

Well-Known Member

Well thank you. I guess this is not typical for me. My last build was a frame off Jeep CJ-7 and that took me the better part of 5 years to complete. I also have an 81' Bronco that I was supposed to start a long travel sand truck build on, but that was put on the back burner. I've been looking at this Dart the the past 40 years in my parents garage dreaming of driving it. Basically out of the blue this past summer, my dad tells me that he'll never get to rebuilding the car and he knew that I would actually get it going so he gave it to me. I was completely shocked and of course excited, but I wasn't prepared for a build like this at that time. So, I took care of a bunch of things at home and sold a motorcycle and some other stuff to prepare for when I pick up the Dart. I knew that i'd have to get it running/driving in 6 months or so or it would turn into another long term build, which I just couldn't do again. So I picked the car up in late December and was able to dive into it right away. I'm not gonna lie, this virus crap has allowed me hours and hours of extra time on the car I wouldn't have had if things were normal. I'm still hoping to be driving and enjoying the car by July/August if things go well, maybe sooner.The waiting is the hardest part. I can't believe how much youve got done in just a few month. Impressive.

I don't see anything standing in your way!

itchy666

Well-Known Member

Spring perches relocated and final welding complete on the housing.

View attachment 1715463668

youre obviously a Welder by trade?

View attachment 1715463669

View attachment 1715463670

View attachment 1715463671

black954

Well-Known Member

Yes, I’m a Union Boilermaker for the past 21 years. I’m not a perfect shop welder, but a high pressure vessel welder. I’m trying to get up to the level of all these badass Instagram shop welders, but that takes time LOL

black954

Well-Known Member

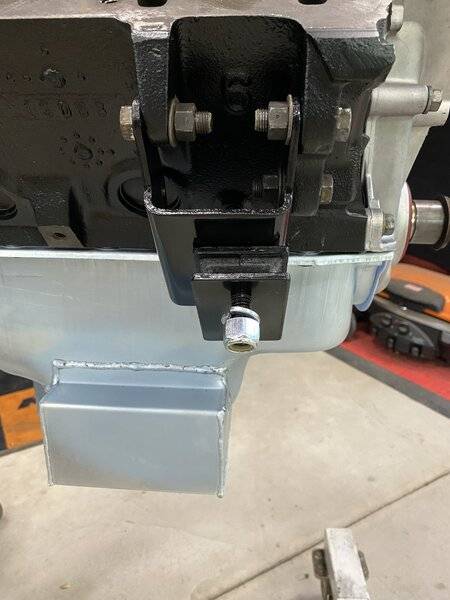

I made some progress on the intake going from a spread bore to square bore. I still have to touch up the corners and radius the transition into the runners. Also, the motor mounts and distributor came in and I cleaned up the original shifter boot. Still waiting on my heads......

black954

Well-Known Member

A few updates. I decided to have my cam degreed in so I build a stand to transport the short block back to the machine shop to have them do it. I also scored a nice set of Doug’s headers. I’ll sand blast them and paint them with Cerakote Tungsten high temp ceramic paint. I’m sure it will hold up much better than whatever Doug’s uses.

abdywgn

dismantler

I like the simplistic engine transport stand! Do you add caster for the garage?

black954

Well-Known Member

Lol I did not. That’s a great suggestion though, I’m going to have to add them now.I like the simplistic engine transport stand! Do you add caster for the garage?

black954

Well-Known Member

3” stainless self aligning V-bands added to the collectors. I’ve never liked the 3 bolt collectors

black954

Well-Known Member

All finished up

black954

Well-Known Member

I dropped off the short block at Opel Engineering on Thursday to have the cam degreed in. Unfortunately I got a call saying the Mopar Performance 3 way adjustable timing set didn’t have enough adjustment to get the timing right. So I ordered a 9 way adjustable timing set from Hughes and it arrived the next day. Opel called and I was able to pick it back up Friday afternoon. Pretty fantastic turnaround if you ask me. Then I was able to continue assembling the engine. Next I will measure for pushrods so I can finish the engine and get it installed.

black954

Well-Known Member

I assembled the coolant crossover lines today. I gasket matched the intake runners as well. I’ll post some pics after I get the intake all cleaned out and washed up.

-

Similar threads

- Locked

- Replies

- 0

- Views

- 2K

- Locked

- Replies

- 4

- Views

- 613

- Locked

- Replies

- 1

- Views

- 278

- Replies

- 9

- Views

- 548

- Replies

- 0

- Views

- 590