stock stamped steel gaskets were ~.020

Are your pistons flat tops?

With valve reliefs?

What year is that engine?

Ima guessing those are already aftermarket pistons. And 3cc for 4 eyebrows is not gonna be enough.

And unmachined early 360 heads are closer to 72/74 ccs

IMO, if you put a cam into this combo, with a later closing intake angle, you are heading straight for disappointment.

If you want pep with a smogger-teen, start with a 2800TC, and gears of 3.23 or more. Cheapest pep you can get.

360 heads with the factory cam are as good as no WOT power improvement, but are accompanied by a less-peppy bottom end.

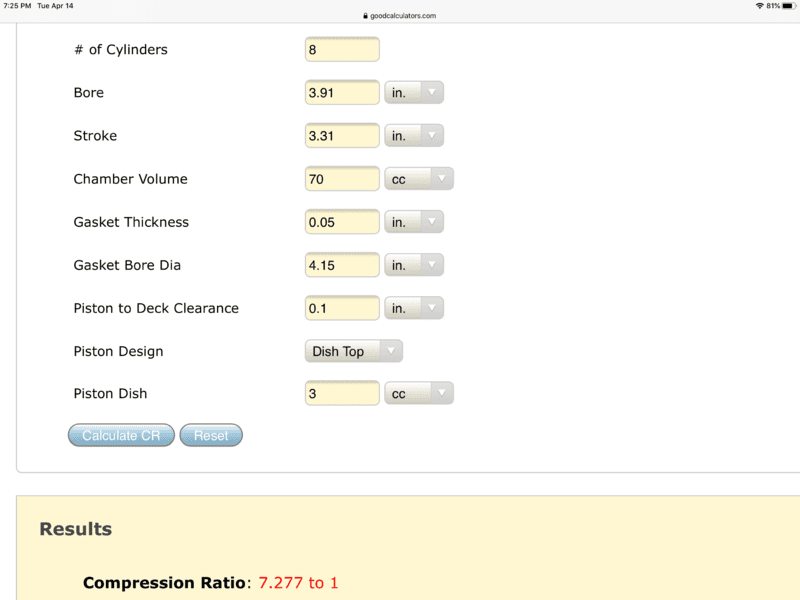

Your numbers add up to 11.3(gasket) + 19.8(deck) +3(eyebrows) +70(heads)= 104cc total chamber volume.

and at .020 overbore, your swept is 651.3, and so

(659+104)/104=7.33Scr

But, those 4 reliefs are probably closer to 6 per set, and a swap to .028(6.3cc) composition headgaskets, and uncut J heads at 73cc, comes to

6.3+19.8+6+73=105.1, so Scr comes to 7.27; close enough.

I gotta tell ya, there is no way I would screw this together like this.

If you have to keep those pistons, Then I would be looking for some/any closed chamber heads. Say you found a set of old 318 hi-swirls at 60cc, then

6.3+19.8+6+60=92.1 and Scr comes to 8.16, which IMO will still suck. Between 7.3 and 8.16 you will not feel any WOT power difference. My chart says less than 2% ..... At Part Throttle, maybe, but you will need to be very familiar with the old cylinder pressure.

What you need to do is to get rid of those 19.8cc below the decks! With the lightly milled 70cc heads this then makes 82.3cc and Scr=9.00

With the stock cam's Ica of ~48*, this will make ~160psi@500 ft elevation.

Now yer cooking

But at 140 psi before teardown, I wouldda spent the money on a TC first, and if you have 2.76 rear gears , those gotta go.

The 2800 would allow the engine to wind up to close to peak torque, which could be 100 or more footpounds higher than the stocker. This calculates to 100x2800/5250= Plus 53hp at the crank . You can't touch that with compression.

3.23 rear gears over 2.76s, is an improvement of 3.23/2.76=plus 17% in torque multiplication, making your teener feel 17% bigger. If your engine makes 280 ftlbs at 2800rpm, these new gears will make it feel 48 ftlbs bigger, about half of what the TC did. Together this adds up to 150 ftlbs or 150/280=~54% more torque, on the launchpad. You'll need a supercharger on the 7.5 engine to equal that, at factory stall.

Happy HotRodding