yellow rose

Overnight Sensation

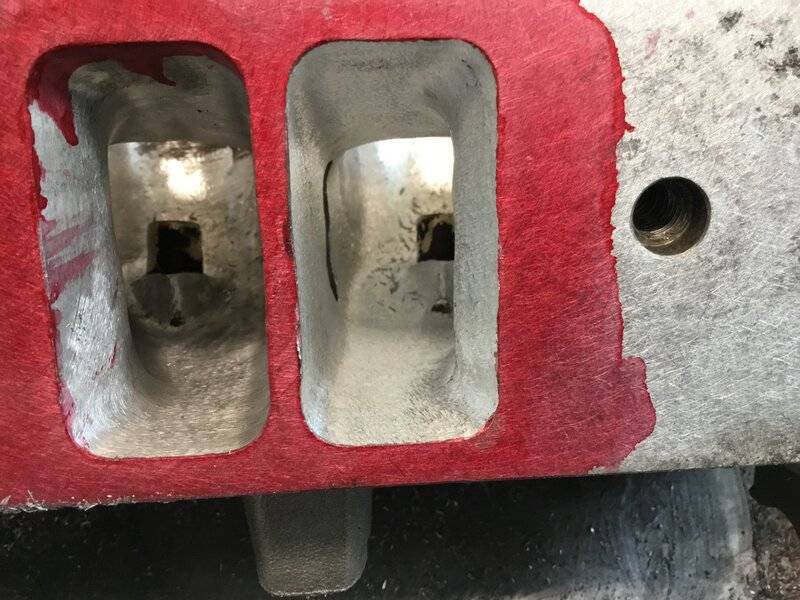

Here is one intake port that I just finished. First burr finished port I’ll put my name on. Every try before this was a GIANT suckfest and looked way worse that this does. I’m going to send this.

Here is one intake port that I just finished. First burr finished port I’ll put my name on. Every try before this was a GIANT suckfest and looked way worse that this does. I’m going to send this.

View attachment 1715675301 View attachment 1715675302 View attachment 1715675303 View attachment 1715675304

what was the method you used to get that rippled finish?

you mentioned using a bent burr before..

Here is one intake port that I just finished. First burr finished port I’ll put my name on. Every try before this was a GIANT suckfest and looked way worse that this does. I’m going to send this.

View attachment 1715675301 View attachment 1715675302 View attachment 1715675303 View attachment 1715675304

Do you put valves in when you do the chambers. If you don’t give it a try as then you can get right up

To the seat with zero worry of hitting the seat.

I’m thinking my junk will always be slow because I’m not making my stuff look like that. No way no how.

I learned a lot of what I know by testing and looking at pictures of other guys work. Many of those mentioned above and their work sure as heck didn’t look like that. When photobucket got greedy years ago it practically ruined this great post but if you weed through it you can still find some beautiful work. Photobucket sucks.

Cylinder Head Show and Tell

“Back in the day”, before the burr finish craze........ Larry Meaux’s work was like art.

On the stuff I do that gets the sand rolled finish...... what his stuff looked like is more or less what I was aiming for.

I say to make it look like the moon, with a ton of craters and pass on the roll. Let’s see what happens when we send it...LOL...when I first tried the burr finish on my junk I just could not stomach what it looked like. In fact, when I tested my W5 junk with the tunnel ram on the flow bench, I lost quite a bit of flow using the burr finish. IIRC it was down 20 CFM over a 60 grit paper roll finish.

Also, IIRC the tunnel ram with the 60 grit finish was much more quiet on the bench. That was 21 years ago and I didn’t keep the notes on that stuff. I kick myself for letting that go with the bench, and I kick myself for getting rid of my flowbench.

I know I played with a burr finish again as I started moving the nozzles up from the valve cover rail. I just couldn’t get my head around that finish and the noise it made on the bench.

I’m going to try and get some pictures that are closer to the finish so I can see how close I am to CS and LM.

Interesting enough, looking at the picture of that tunnel ram by LM, it appears that surface is more divot that a raised burr. I remember getting that look years ago with a much more coarse burr that was bigger in diameter and it was a cylinder shape with a radius on the end so it doesn’t dig ditches.

At times I’m thinking it’s not what the burr finish looks like, just that you run a burr over it. Then again, LM said the rougher the better, and Darin Morgan said you can’t get it too rough which is mind boggling to me.

And now I’ve talked myself back into the corner of indecision...I hate that. I usually trust my gut but this has me baffled. Do I try and make it a bit rougher, or do I say screw it and paper roll it????

I read a car craft article about a pock marked combustion chamber finish. like the finish of a golf ball done by a nail set or something. It was totally opposite of what that rag had been preaching for years (port and polish, knock down high points for pre-ignition reduction, etc) that it took me by surprise that they would even publish that. Check out this fish scale finish on youtube, Veicomer does alot of this stuff.

I say to make it look like the moon, with a ton of craters and pass on the roll. Let’s see what happens when we send it...

Well, you got guts...ok...I’ll send it rough. I want to be standing there when they hit the bench. I know Dan won’t care. I really don’t care about the flow numbers as much as I care about how the ports sounds. If it sounds like garbage I’ll probably go sit in the corner of the shop and wet myself while sucking my thumb. At that point, that will be the only thing left to do. I guess I could crap myself. So I do have that option.

Whatever happens there’ll be video...

Whatever happens there’ll be video...Several of the builds I was the happiest with got the sand rolled finish.

It worked before, I figure it’ll work again.

The highest HP motors I’ve done had cnc’d ports with the ridges left in them.

Overall, I think it’s fairly obvious that the port design and flow will ultimately have much more of an impact on the power than whether or not the port walls are smooth or rough.

At one point during a discussion on this subject over on YB, Chris Uratchko said his best build had smooth ports.

That guy does some damn impressive builds.