daves66valiant

68 Dart 340/727:66 Signet Vert 340/5spd: 68 D100

Poorman’s alignment. First timer but everything passes the eyeball test. I’m sure it’s not perfect but it’ll get me down the road until I get it onto a proper alignment rack. Have researched some DIY tools but haven’t pulled the trigger.

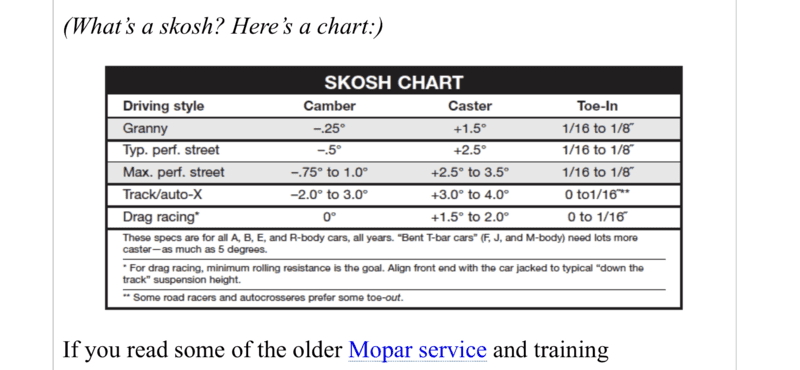

Set my ride height. Did the string line around all fours. Then devised a straight edge on the rim with magnets. Used an manual angle finder but forgot I had my digital angle finder that I use for my table saw. From the looks of it I have the camber at -2* on the drivers side. Got -1.4* on the passenger side. These setting are with the cam bolts maxed just to see how much negative camber I could get. I have not figured out the Caster but will get the camber set to -.5 to .75 when I get a chance. I eyeballed the toe in at 1/8”. I’m looking forward the seeing how close or how far the actual numbers are on the rack.

On the sway bar the QA1 strut rods are a little thick. I believe I need to extend the end-link sleeves by 1/2-1” to clear the sway bar end. Opinions on this please. Sleeves aren’t straight up and down either and I’m not sure if I can do much about it either because of the L- brackets supplied by Hellwig.

Set my ride height. Did the string line around all fours. Then devised a straight edge on the rim with magnets. Used an manual angle finder but forgot I had my digital angle finder that I use for my table saw. From the looks of it I have the camber at -2* on the drivers side. Got -1.4* on the passenger side. These setting are with the cam bolts maxed just to see how much negative camber I could get. I have not figured out the Caster but will get the camber set to -.5 to .75 when I get a chance. I eyeballed the toe in at 1/8”. I’m looking forward the seeing how close or how far the actual numbers are on the rack.

On the sway bar the QA1 strut rods are a little thick. I believe I need to extend the end-link sleeves by 1/2-1” to clear the sway bar end. Opinions on this please. Sleeves aren’t straight up and down either and I’m not sure if I can do much about it either because of the L- brackets supplied by Hellwig.