moparmat2000

Well-Known Member

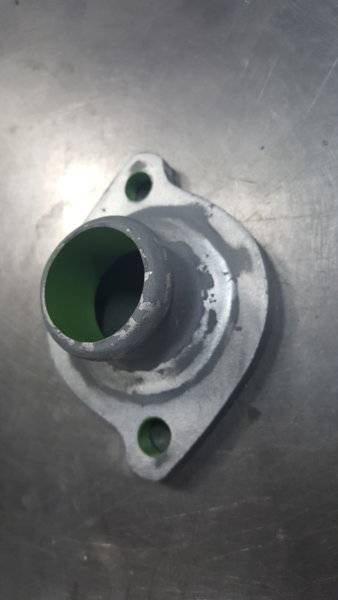

I use JB weld for quite a bit of potmetal repair. If the parts are prepped good it works very well. I had a thermostat housing that was corroded to ****, but solid enough to fix. Thinking this is a great idea in a pinch, especially for our overseas members who may not have access to a replacement cheaply and easily.

I wanted to see if i could actually repair it. Now i know i can just buy another, and was able to secure a good used one from another Fabo member for not too much coin, but i still wanted to see if i could actually fix this one. I feel this thread can be used for a lot of different stuff thats pitted.

After sandblasting the part to pitted clean metal, i mixed up the JB weld epoxy and applied it. Once dry, i sanded it to shape, and applied more to the low spots, cured, and sanded it smooth again, then sprayed the end result inside and out with multiple coats of a fluid resistant epoxy primer made by Akzo Noble. This stuff is tough as nails and its really doubtful this thermostat housing will corrode any further after this. All it needs now is a scuff, and some engine enamel. I will keep this as a spare in case needed.

I can also see the value in this being used to repair corroded and pitted thermostat housing mating flanges on aluminum intake manifolds once they are sandblasted clean.

Hope this helps

Matt

I wanted to see if i could actually repair it. Now i know i can just buy another, and was able to secure a good used one from another Fabo member for not too much coin, but i still wanted to see if i could actually fix this one. I feel this thread can be used for a lot of different stuff thats pitted.

After sandblasting the part to pitted clean metal, i mixed up the JB weld epoxy and applied it. Once dry, i sanded it to shape, and applied more to the low spots, cured, and sanded it smooth again, then sprayed the end result inside and out with multiple coats of a fluid resistant epoxy primer made by Akzo Noble. This stuff is tough as nails and its really doubtful this thermostat housing will corrode any further after this. All it needs now is a scuff, and some engine enamel. I will keep this as a spare in case needed.

I can also see the value in this being used to repair corroded and pitted thermostat housing mating flanges on aluminum intake manifolds once they are sandblasted clean.

Hope this helps

Matt

Last edited: