RAYS 69 MOPAR

Well-Known Member

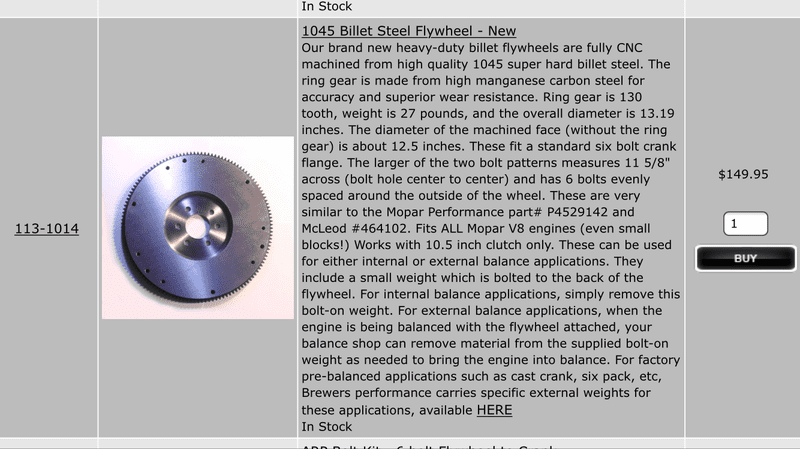

The flywheel that you attached to weight to what are your feelings about putting the weight screwed on ???

It's behind mild 360 car shows and A few scratches here and thereBTW, unless you are down on power, have a 2.44 first gear, a 3.08 rear gear or all 3, why not aluminum?

Those heavy FW's just beat the tire up.

If it's just a DD, steel is ok.

PS how can you be at 150 shipped to your door