HotRod777

Active Member

I’ll pre-game my question by saying yes, I know how to and that I should degree all camshafts. I also have the tools required to do that. I’m just looking for an explanation as to how Hughes specs their cams and how they write their cam cards. I contacted their tech line and was giving a “don’t bother us” answer of “it’s on the spec card”.

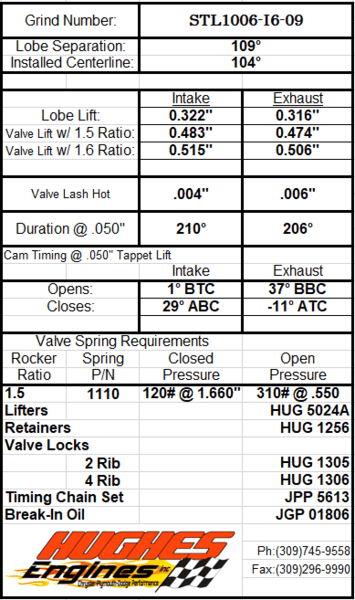

Here is the cam card below:

My question is about the installed centerline.

Do they mean that they grind it on 109° and I’M supposed to manually advance it 5° via a multi key crank sprocket to 104°?

OR

Do they mean that they already grind the 5° into the cam and if you line it up “dot to dot” (and everything else is correct) it will already be at 104°?

The reason I’m asking is that (usually) these specs are in 2° increments. A 9 slot sprocket is in 2° steps... but they want 5°?

That’s why I’m questioning this. If I have to manually advance it I’d have to use the 6° key way and end up at 103° (again assuming everything else is correct).

Any thought are appreciated. Thanks!

Here is the cam card below:

My question is about the installed centerline.

Do they mean that they grind it on 109° and I’M supposed to manually advance it 5° via a multi key crank sprocket to 104°?

OR

Do they mean that they already grind the 5° into the cam and if you line it up “dot to dot” (and everything else is correct) it will already be at 104°?

The reason I’m asking is that (usually) these specs are in 2° increments. A 9 slot sprocket is in 2° steps... but they want 5°?

That’s why I’m questioning this. If I have to manually advance it I’d have to use the 6° key way and end up at 103° (again assuming everything else is correct).

Any thought are appreciated. Thanks!