Headers By Ed.

Good source for parts, some good and clever tips for construction. Not much room for discussion. For cars he was always focused on 4 into 1. I really like is collector cones but can't recall what he had for 2 into 1 collectors.

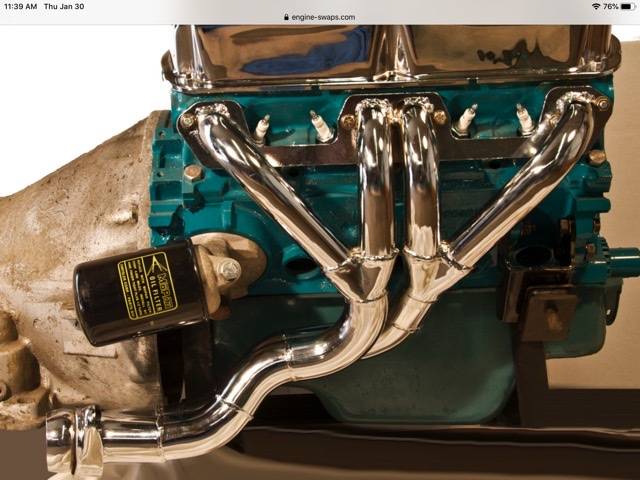

Some pics of Headers by Ed design for small block in a-body in this post.

Header fitment rant, Doug's

Schumacher's Tri-Y

I completely agree with the observations about the merging can have on flow.

The big block design is slightly better in terms of angles but uses the same merge cones.

Definately lots of good ideas for fitment to borrow from.

As far as tube length.

Calvin Elston has posted about the importance of keeping velocity up. If you join Speed Talk, there's a post in the members only section where he discusses a test he made with a log header. The bottom line is try to use a small tube off the port for 8 to 12" and then interupt it whether with a big step or small step isn't as important.

Custom

Brian Slowe made a set of custom st st tri-y for my car.

I'll post some pics for you to get ideas.

It has small (1.5") diameter off the flange. The flange handles the change in shape from the port to round. ( I think I had five flanges made) Some people can blacksmith it, but Brian wasn't happy with his results doing that. You always have to go with what the craftsman is comfortable with. So I did.

The real b_tch with tri-y on these cars is the passenger side - especially if you insist on equal length, as Brian did. IF you're willing to compromise equal length (and Calvin says in many applications its fine to do so within reason) then more room can be found.

View attachment 1715588637

View attachment 1715588645

View attachment 1715588643

View attachment 1715588644

. Summit, Jeg's, Speedway probly a good place to get those 180s now.

. Summit, Jeg's, Speedway probly a good place to get those 180s now.