Hey Guys, I did a search on the forums and found similar threads and advice. It was all greek to me. Simple question. How do I power up the backlights on the gauge cluster to test and make sure I have em all oriented right and everything is working right?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bench Testing a gauge cluster

- Thread starter wsmith

- Start date

-

67Dart273

Well-Known Member

You have to make it "rigged" to simulate "in car" so use your head.

Apply 12-14V to the ignition connection feeding TO the instrument regulator / limiter.

Each gauges comes out on a pin to each sender. These senders all have the same resistance for the same gauge reading, in other words, "full scale" for temp "hot", fuel "full" and oil (if equipped)

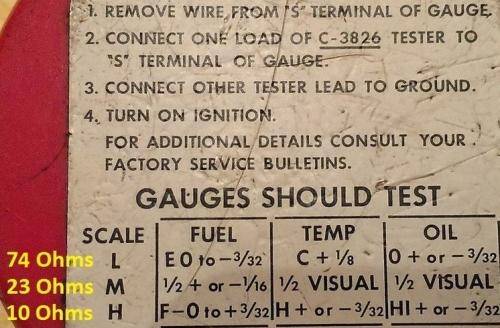

Here's a tester that someone edited to show the resistances

There are a few ways to do this.......(Used to be Radio Shack LOL) Buy the three resistors from someplace, Digikey, Mouser electronics. Or get a big wattage rheostat (variable resistor). If you have a fuel sender that still works, you can move it to whatever resistance you need using your meter and then clip it in to the sender terminal and ground.

Apply 12-14V to the ignition connection feeding TO the instrument regulator / limiter.

Each gauges comes out on a pin to each sender. These senders all have the same resistance for the same gauge reading, in other words, "full scale" for temp "hot", fuel "full" and oil (if equipped)

Here's a tester that someone edited to show the resistances

There are a few ways to do this.......(Used to be Radio Shack LOL) Buy the three resistors from someplace, Digikey, Mouser electronics. Or get a big wattage rheostat (variable resistor). If you have a fuel sender that still works, you can move it to whatever resistance you need using your meter and then clip it in to the sender terminal and ground.

harrisonm

Well-Known Member

67 Dart 273 is 100% correct when he tells you about the resistance needed for needle deflection. There is another way to test the gauges by using a few flashlight batteries. I have done this and it works fine. How to test the gauges is at the end. First is a brief explanation of why the test works. The oil pressure and temp gauges each have 2 pins on the back. The gas gauge has 3 pins. The needles in the instruments are deflected when current flows through a bi-metal coil they are attached to (like in a home thermostat) and makes it twist a little as it heats up (more current flowing) or cools down (less current flowing). In the car, the instrument voltage regulator drops 12 volts down to about 5 volts, and that 5 volts is what flows through the instruments. Take the temp gauge for example. One pin on the back has 5 volts coming into the gauge, and the other pin has a wire going out to the temp sending switch that is screwed into the intake manifold (and, consequently grounded to the engine). When the engine is cold, the resistor inside the temp sending switch does NOT allow any current to flow through it and into the ground. Since there is not a complete circuit, that means that current is not actually flowing through the instrument. So the needle does not move and stays on COLD. When the motor starts to warm up, the resistor inside the temp sending switch starts to allow some current to flow through it and into the ground. Now there is a complete circuit, current is flowing through the instrument, that current will heat up the bi-metal coil, and the needle will move. The hotter the motor gets, the more current the resistor will allow to flow to ground, the more current flows through the coil, and the more the needle moves. Same idea with the oil pressure and gas gauges. They may have different types of sending switches, but they still simply regulate the amount of current that can flow to ground. That is why the gas tank has to be grounded. To test oil pressure and temp gauges, place two 1.5 volt D cell batteries end to end to get about 3 volts. Use jumper wires to touch the pins on the back side of the gauge. 3 volts will give you about ½ deflection with the needle. This way you will know if the gauge is working. You may not know how accurate the gauge is, but you will know if they work. The gas gauge has 3 pins. You only have to touch two. They are marked, but I will have to check on the markings on Saturday morning to tell you which 2 to use. I’ll also post a few pictures from an article I wrote on this subject for Mopar Muscle Magazine.

Guys I just want to see if the backlights work....

67 Dart 273 is 100% correct when he tells you about the resistance needed for needle deflection. There is another way to test the gauges by using a few flashlight batteries. I have done this and it works fine. How to test the gauges is at the end. First is a brief explanation of why the test works. The oil pressure and temp gauges each have 2 pins on the back. The gas gauge has 3 pins. The needles in the instruments are deflected when current flows through a bi-metal coil they are attached to (like in a home thermostat) and makes it twist a little as it heats up (more current flowing) or cools down (less current flowing). In the car, the instrument voltage regulator drops 12 volts down to about 5 volts, and that 5 volts is what flows through the instruments. Take the temp gauge for example. One pin on the back has 5 volts coming into the gauge, and the other pin has a wire going out to the temp sending switch that is screwed into the intake manifold (and, consequently grounded to the engine). When the engine is cold, the resistor inside the temp sending switch does NOT allow any current to flow through it and into the ground. Since there is not a complete circuit, that means that current is not actually flowing through the instrument. So the needle does not move and stays on COLD. When the motor starts to warm up, the resistor inside the temp sending switch starts to allow some current to flow through it and into the ground. Now there is a complete circuit, current is flowing through the instrument, that current will heat up the bi-metal coil, and the needle will move. The hotter the motor gets, the more current the resistor will allow to flow to ground, the more current flows through the coil, and the more the needle moves. Same idea with the oil pressure and gas gauges. They may have different types of sending switches, but they still simply regulate the amount of current that can flow to ground. That is why the gas tank has to be grounded. To test oil pressure and temp gauges, place two 1.5 volt D cell batteries end to end to get about 3 volts. Use jumper wires to touch the pins on the back side of the gauge. 3 volts will give you about ½ deflection with the needle. This way you will know if the gauge is working. You may not know how accurate the gauge is, but you will know if they work. The gas gauge has 3 pins. You only have to touch two. They are marked, but I will have to check on the markings on Saturday morning to tell you which 2 to use. I’ll also post a few pictures from an article I wrote on this subject for Mopar Muscle Magazine.[/QUO

TE]

Yote

Well-Known Member

A simple continuity test on the pins with bulbs in place should assure you that at least that part of the circuit and bulbs are in working condition.

Yote

Yote

We used a 6V lantern battery and connected it to back of circuit board. Sorry I can't remember exactly where.

TrailBeast

AKA Mopars4us on Youtube

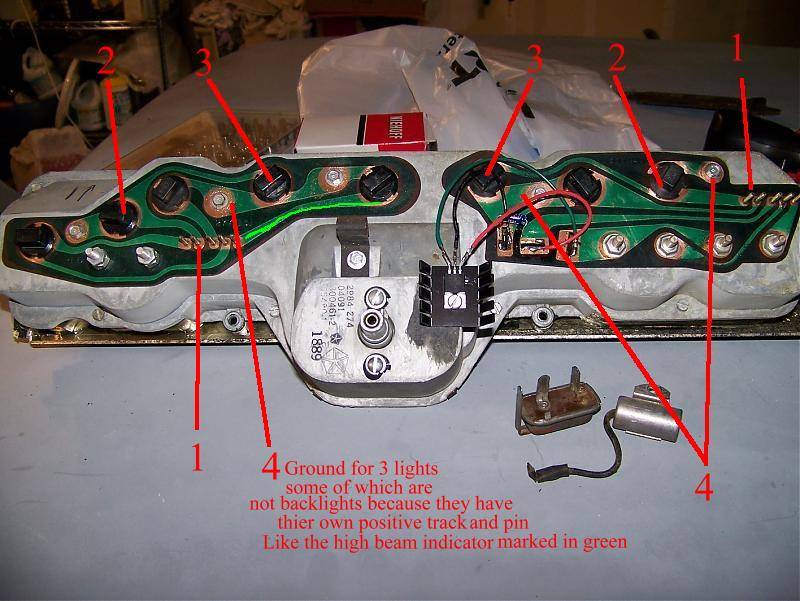

The simplest way to do what he is asking is to find one of the backlight bulbs and follow the copper tracers to the pin that they get power from.

This is the split style where it has two sets of pins (one left and one right)

Note that 1 2 3 and 4 are the same things, just the others side of the cluster.

1 is the pin that supplies power 12v to 2&3 and 4 is the ground.

The cluster pictured has a backlight pin for each side.

Note in this picture that the pin (number 1) has a green track that goes to two bulbs (number 2 and 3) and that number 4 is the ground for that one bulb (tracks with a screw through them are ground tracks.)

Multiple bulbs that use the same track that is connected to a pin on the back of the cluster are usually backlights.

So in the case of this picture pin 1 is the positive for those two bulbs (2&3)

You can use the cluster housing as a ground, and 12v supplied to pin 1 should light those two bulbs.

Bulbs that use a single track to a single pin and no bulbs are usually gauge connections.

DO NOT supply those with 12v without having a good grasp of what 67Dart273 said above.

Hope this helps

This is the split style where it has two sets of pins (one left and one right)

Note that 1 2 3 and 4 are the same things, just the others side of the cluster.

1 is the pin that supplies power 12v to 2&3 and 4 is the ground.

The cluster pictured has a backlight pin for each side.

Note in this picture that the pin (number 1) has a green track that goes to two bulbs (number 2 and 3) and that number 4 is the ground for that one bulb (tracks with a screw through them are ground tracks.)

Multiple bulbs that use the same track that is connected to a pin on the back of the cluster are usually backlights.

So in the case of this picture pin 1 is the positive for those two bulbs (2&3)

You can use the cluster housing as a ground, and 12v supplied to pin 1 should light those two bulbs.

Bulbs that use a single track to a single pin and no bulbs are usually gauge connections.

DO NOT supply those with 12v without having a good grasp of what 67Dart273 said above.

Hope this helps

-