cruiser

Well-Known Member

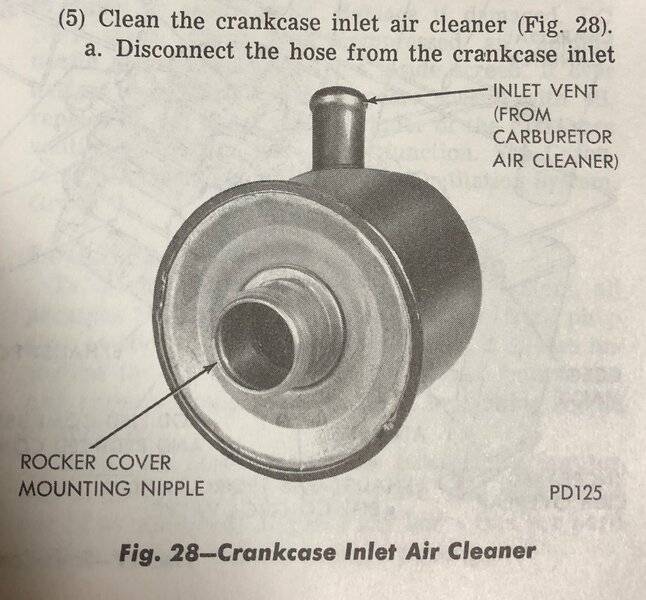

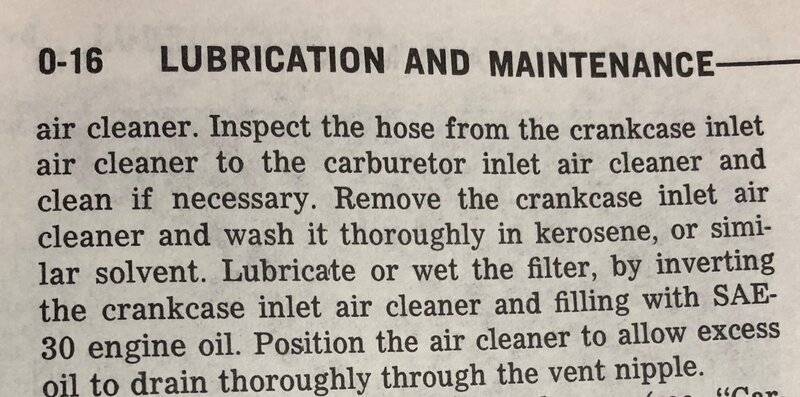

Good evening kiddies! Before we begin, I'd recommend that you preposition yourself in bed with some cookies and a glass of milk. As boring as this topic will be, at least you'll be ready to fall asleep immediately after reading it - which is the whole point of my series. Comfy now? Good! So here goes. Few of us lie awake at night thinking about the crankcase inlet air cleaner (CIAC) on our cars. As you may know, the internal portion of our engines is ventilated to the atmosphere by a system that flows ambient air through the CIAC, the PCV valve and the carburetor. The purpose of this system is twofold: First, to capture oil fumes and blow-by gases, and second to route them to be burned through the carb instead of being vented to the atmosphere. The first two photos below are from the factory shop manual and outline the recommended servicing of the CIAC. My 1974 Duster still had its factory original CIAC, but it was in pretty rough shape. Note the corrosion in the third and fourth photos. Step one was to soak the CIAC in gasoline to remove the years of oily residue inside, then immerse it in Evapo-Rust for 24 hours to remove any corrosion in the internal baffles. Note the rusty crud (not to be confused with Rusty Rat Rod, a frequent FABO contributor) that came out in the sixth photo. I then cleaned it inside and outside with Dawn liquid detergent and hot water. This process remover the original factory finish, which appeared to be a hastily applied single coat of satin black paint. I let a hair dryer blow hot air through it for 30 minutes to dry the inside, then painted it with four coats of Krylon Fusion #2732 Satin Black spray paint. It came out looking like a factory fresh new part. After curing for 48 hours, I lubricated the inside of the CIAC with 30W motor oil as per the shop manual. Next, I installed a new repro rubber grommet in the valve cover, as the old one was cracked and deteriorated. The eighth photo shows the new grommet alongside the correct ribbed breather hose which I was able to re-use. I didn't want to use off the shelf rubber hose from a parts store, and repro ribbed hose is readily available. I couldn't see putting all that work into the CIAC, then putting the wrong hose on it. Yes, very obsessive - compulsive, I know but I have to look at it every day and its gotta be right. The final two photos show the reinstalled unit and it looks great. Now I've just got to repaint the engine to look as good as the CIAC , which will be another chapter. Naturally, I had to take Dusty out for a drive after installing her reconditioned unit, and as always she started right up and happily sucked all those nasty oil fumes through the engine and burned them up. What a lovely feeling, the 49 year old Plymouth engine purring along like it was built yesterday. So there you have it, kids. If this story didn't make you drowsy, I don't know what will. Now turn off the light, roll over and go to sleep. Night night!

Last edited: