pishta

I know I'm right....

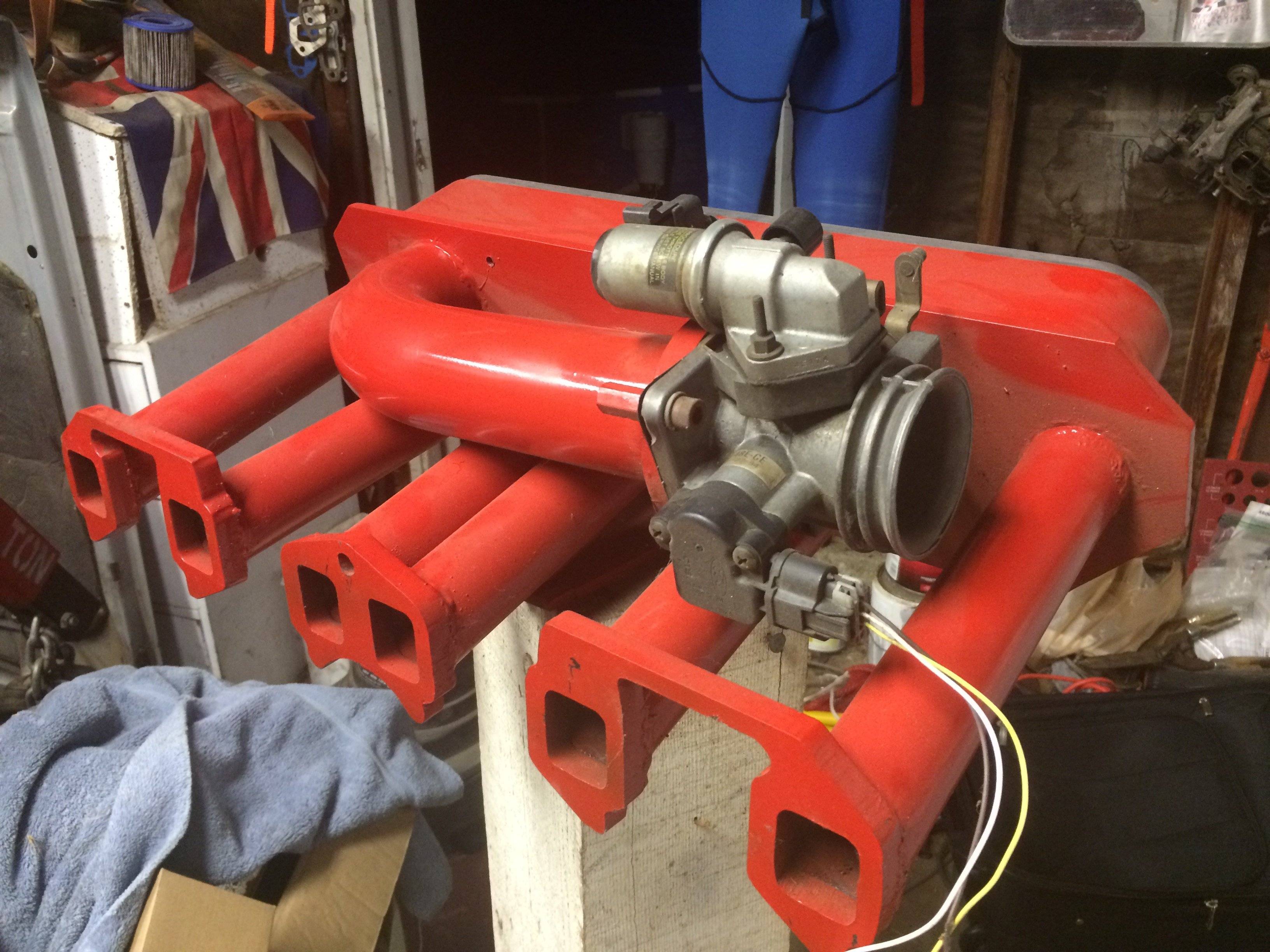

I fashioned this out of EMT, a piece of plate metal and an old Edelbrock cast valve cover. I bought the flanges off Ebay. I made the runners as long as the original Ramchargers formula for intake valve timing off a stock camshaft, I think it was around 240 degrees. I picked the 4th or 5th wave to keep it under 10 inches. TB Ram tube length doesnt factor in much according to some design sites and I put it here to keep the package as narrow as possible as its in a narrow A and the M/C is over there. With no EFI bungs at a 45, you can make it pretty narrow.

It has an integral exhaust manifold heat stove plate which makes a nice pad to mount the manifold to. This is turbocharged so there is plenty of heat to prevent icing, and the injectors are downstream so its completely dry. You can make some tricky bends with a dry intake, just look at some stock plastic intakes on the 3.8 motors. I used a good rubber valve cover gasket and sealer for the plenum. I used a Ford Windstar 3.8 TB as it has a PW idle air control motor as opposed to a stepper motor that my MS2 could not handle. Im also using a Ford EDIS-6 ignition with a 36-1 degree wheel off the crankshaft damper. I milled the teeth into the stock slant dampers outer ring and will make a 3 prong yoke to keep the ring from slipping by bolting it to the rigid inner hub and extending the 3 fingers out to 3 dimples Ill drill into the outer ring. That should keep things in line. I tried to make some teeth into a more rigid mount power steering pulley but botched it badly so I went with plan B. Usually turbos dont mind shorter runners but when I first started this project, it was without the turbo. The 3 BAR MAPP is in the MS2 controller so a few nipples off the plenum will work with that.

It has an integral exhaust manifold heat stove plate which makes a nice pad to mount the manifold to. This is turbocharged so there is plenty of heat to prevent icing, and the injectors are downstream so its completely dry. You can make some tricky bends with a dry intake, just look at some stock plastic intakes on the 3.8 motors. I used a good rubber valve cover gasket and sealer for the plenum. I used a Ford Windstar 3.8 TB as it has a PW idle air control motor as opposed to a stepper motor that my MS2 could not handle. Im also using a Ford EDIS-6 ignition with a 36-1 degree wheel off the crankshaft damper. I milled the teeth into the stock slant dampers outer ring and will make a 3 prong yoke to keep the ring from slipping by bolting it to the rigid inner hub and extending the 3 fingers out to 3 dimples Ill drill into the outer ring. That should keep things in line. I tried to make some teeth into a more rigid mount power steering pulley but botched it badly so I went with plan B. Usually turbos dont mind shorter runners but when I first started this project, it was without the turbo. The 3 BAR MAPP is in the MS2 controller so a few nipples off the plenum will work with that.