furrystump

Well-Known Member

- Joined

- Nov 13, 2004

- Messages

- 2,103

- Reaction score

- 1,700

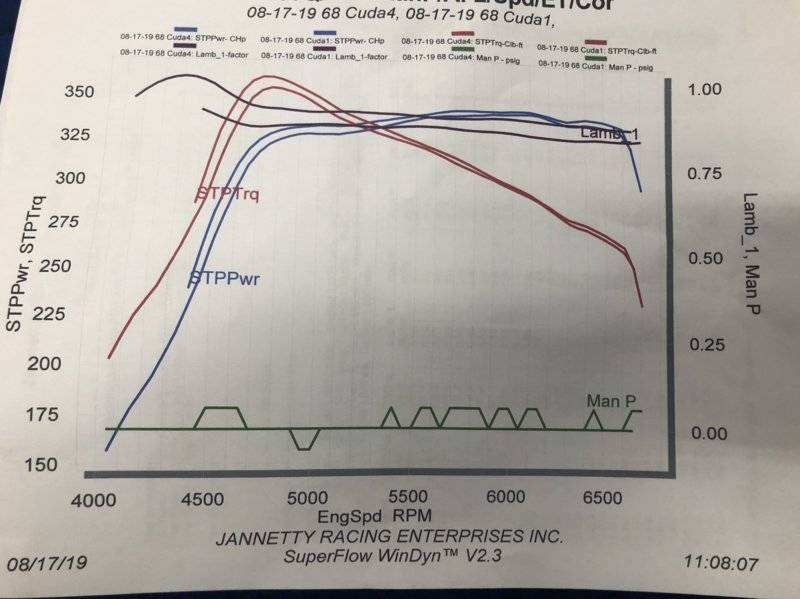

Ok, ran the car on chassis dyno and here’s the graph. The small improvement was from drilling out the accel pump nozzle just a touch. The combo is

It seems to me that it is too “smooth” for lack of a better word, like it’s hitting the limit of a part and saying “you shall not pass” at 6500 it started to touch the rev limiter.I think mine is a 78 360 block bored to .040. With Icon forged flat top pistons .010 in the hole. Scat h beam rods and Scat 4” cast crank. The heads are x heads ported by Dwayne Porter of Porter Racing Heads. Flow about 280 cfm intake. The cam is an Engle flat tappet intake .557 lift 245 degs at .050 lift. Exh is .551 lift with 261 degs at .050 lift. 112 degs lobe seperation. Intake is stock 68-69 340 manifold with the divider cut down and smoothed out a bit. Stock hipo 340 exh manifolds. Eddy 800 cfm AVS thunder series. Two fuel pumps. A big Carter mechanical and a Holley red pump back at the tank with Holley hydra mat inside. Mallory billet distributor and MSD 6al. Cope Racing trans 727 auto shift with a PTC 9.5 “ converter. 4:10 rear gear in an 8 3/4”. TTI 2.5” exhaust. Original 340 front torsion bars with QA1 R’s on the front and 1” over arched leafs on the rear with lame KYB shocks. Car is original 68 Barracuda 340-s Fastback, weighs 3445 lbs with me in it. Tires are f70-14 polyglas redlines. Best run is 1.71 60’ 11.83 at 116. Shifting at 6300 rpm.