No need for body and glass shop. This is DIY all the way. (I do have a good glass guy available if I have a problem) other than that my lack of a budget for this needs to go for parts.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cinnamon 75 Duster \

- Thread starter zkx14

- Start date

-

A little more damage control today. As I mentioned back in March, the calipers I just put on in the fall were already covered in rust. I pulled them loose (without disconecting) cleaned off the rust , wiped with laquer thinner and painted. Also cleaned up the new rotors and clear coated all but the pad contact area.

Last edited:

txstang84

Well-Known Member

Diggin' it

I had done some repairs to the cluster previously. Most of the places the screws thread in were cracked up pretty bad. I used plastic epoxy to rebuild them. When I replaced the fuel tank, I figured out the fuel gauge wasn't working. I picked up another cluster at a yard last fall. Mostly for the gage, but was considering using the whole thing. It has a chunk out from somebody trying to get it out without dropping the column. Decided to just use the gage in my old cluster for now, so did some repainting. I had a can of spray chrome but was sure I would just make a big mess if I sprayed it. Instead I sprayed it in a puddle and brushed it on. I think its a little better than the silver model paint I tried first. Also did the black and the orange needles and touched up the brown.

txstang84

Well-Known Member

Looks good to me dude

Put it back in and the gauges all work. Might need a couple bulbs... Not screwing it fast for now.

I got a windshield, so figuring on doing that and all dash area work soon. I have a much nicer dashpad that just needs a small crack repair at lower right. Will need to repaint everything, replace wiper seals and bushings, check out cowl, rebuild the heater/ac box...

Did have an oops - managed to break the shift pointer. Anybody got one to spare? If not I can probably find one at the yard.

I got a windshield, so figuring on doing that and all dash area work soon. I have a much nicer dashpad that just needs a small crack repair at lower right. Will need to repaint everything, replace wiper seals and bushings, check out cowl, rebuild the heater/ac box...

Did have an oops - managed to break the shift pointer. Anybody got one to spare? If not I can probably find one at the yard.

Last edited:

This was from a couple weeks ago... Magnum headlights were pretty scratched up. I got a 3M kit. They start with 500 grit discs, but not enough -I ended up using a sheet of 400 to get the coating off. Other than that the kit did as pretty good job. Before and after...

Back to the Duster...

I am reworking a set of absorbers for the bumpers. The originals were really rusted (far worse than the one in pic) So, got a better set to start with. Cleaned, painted and made new 'dust boots' from sheet of rubber.

I am reworking a set of absorbers for the bumpers. The originals were really rusted (far worse than the one in pic) So, got a better set to start with. Cleaned, painted and made new 'dust boots' from sheet of rubber.

I welded up a cart a couple days ago from some metal I had laying around . I did have to buy one set of casters.

Disconnected almost everything yesterday, Pulled rad, alt, AC, column etc.

With the car on the ground, It had about an inch of clearance above the cart. Unbolted crossmember and lowered the tranny with a jack (pan sits on flat cross bar), then pull the wheels and lower front till cart rails cradle the K. Popped the T-bars, unbolted UCA's, Tied up the calipers, Unbolted the K and lift the car....

Maybe not quite that simple; I did initially miss the e-brake intermediate cable, speedo connection to trans and a couple other small items that caused hang-ups. Once I had it on the ground I ran a chain across it to hold th rotors off the ground and drug it in the garage with the lawn tractor.

Overall it went really well. Worst part was I picked a couple 90 degree plus days to do it.

Disconnected almost everything yesterday, Pulled rad, alt, AC, column etc.

With the car on the ground, It had about an inch of clearance above the cart. Unbolted crossmember and lowered the tranny with a jack (pan sits on flat cross bar), then pull the wheels and lower front till cart rails cradle the K. Popped the T-bars, unbolted UCA's, Tied up the calipers, Unbolted the K and lift the car....

Maybe not quite that simple; I did initially miss the e-brake intermediate cable, speedo connection to trans and a couple other small items that caused hang-ups. Once I had it on the ground I ran a chain across it to hold th rotors off the ground and drug it in the garage with the lawn tractor.

Overall it went really well. Worst part was I picked a couple 90 degree plus days to do it.

Last edited:

Pulled fogged front glass, dash and heater box today. Got a pile of parts here to start putting things together. DMT full gasket and heater box kit. New gaskets and clips for front and back glass. Picking up new front glass tommorow. Got all my suspension stuff to go back in. Gonna be Busy,Busy,Busy...

roadrunnerh

Well-Known Member

You're doing really good work man, replacing metal with metal. Keep it up!

Keep up the good work.

Why did you pull the motor, just to clean and paint?

Why did you pull the motor, just to clean and paint?

metallidart

member me?

Looking good! I love seeing builds like this.

Keep up the good work.

Why did you pull the motor, just to clean and paint?

That and I wanted to redo the suspension anyway. There's a couple rust spots inside frame rails I need to get to. Also surface rust under trans tunnel and other areas near impossible to treat with everything in there. So, just best to pull it out and get at everything right. It seemed to run good but had some small leaks, so while I am at it will at least regasket and check if any other issues.

Cleaned some more junk out of the cowl. Between the vacuum, blow gun, a coat hanger and garden hose - I actually think I got it all! I then sealed the collar in with neoprene roof calk. On a 95 degree day the stuff is almost self leveling. Basically I pumped it in at a few points around the inside of the ring and reached in with a glove on and smeared it around. Leak tested the next day and its good. Finished cleanup on inside of firewall and got that painted (rustoleum spray cans).

Rebuilt the HVAC boxes with DMT kit. You will notice the evap, compressor, etc hanging around in the pics. Last I had it together it all worked. So, I am working around it.

Had some small holes in the bottom of windshield gasket area. Most went into the cowl, but one on pass side leaked down the right pillar. I used JB Weld to fill them and it worked out pretty well. Cleaned the vinyl and glue off the top. I will be replacing that. I was originally going to do that later in the project, but realized when cleaning up the windshiel area that the vinyl goes UNDER the moulding clips.

Next cleared out the remaining items from the bay and from under hood. Did all needed repairs and cleaning. And fiinally today I got some finished paint on it. Using acrylic enamel on this stuff, door jams etc. Planning to do base/clear on outer body.

Rebuilt the HVAC boxes with DMT kit. You will notice the evap, compressor, etc hanging around in the pics. Last I had it together it all worked. So, I am working around it.

Had some small holes in the bottom of windshield gasket area. Most went into the cowl, but one on pass side leaked down the right pillar. I used JB Weld to fill them and it worked out pretty well. Cleaned the vinyl and glue off the top. I will be replacing that. I was originally going to do that later in the project, but realized when cleaning up the windshiel area that the vinyl goes UNDER the moulding clips.

Next cleared out the remaining items from the bay and from under hood. Did all needed repairs and cleaning. And fiinally today I got some finished paint on it. Using acrylic enamel on this stuff, door jams etc. Planning to do base/clear on outer body.

Last edited:

Started getting some things back together. Cut insulation for firewall from roll (from DMT) I decided I did not want the shiney stuff visible, so found that dark gray primer adhered pretty good and looked similar to the rubberized stuff from factory. Under dash is same insulation with shiny side up - attached with weatherstrip adhesive. Put the wiper motor and pivots in and attached the linkage. Installed the heater and AC boxes.

Also starting to populate the engine bay. Got a good blower and gas pedal assembly from FABO members. A little cleaning and painting and they are in. Cleaned up and re-taped some areas of the harness. battery tray and horns plus a bunch of other stuff. Will be getting some new wiring clips and working on routing as it comes together.

Also starting to populate the engine bay. Got a good blower and gas pedal assembly from FABO members. A little cleaning and painting and they are in. Cleaned up and re-taped some areas of the harness. battery tray and horns plus a bunch of other stuff. Will be getting some new wiring clips and working on routing as it comes together.

Last edited:

roadrunnerh

Well-Known Member

Nice!

rlevs

Well-Known Member

wow nice work keep it up

very nice and what he said^^^^

Been working on the dash. I will catch up on some of the other stuff I did to it in another post. For now I want to show my new speaker.

So I get the dash out and realize the speaker is toast - as apparently most of them are. I considered going to a dual 3.5 and either make a bracket or buy from the guy on here that makes them. Then I saw these RetroSound dual cone replacements. Anyway I went to Carlisle Friday and they had them. Figured buy it, speaker in hand, quick and easy install - no problem.... Before I continue on the speaker... gotta say Carlisle was great, but I need to plan for 2 days next year. My daughter went with me. She's getting her licence soon and enjoyed the cars. (she was taking pics of all the purple cars) We got to see the A's and E's and maybe 3/4s of the swap area. A few other bits and pieces and the day was over. With a little luck I may take the Duster and camp there next year.

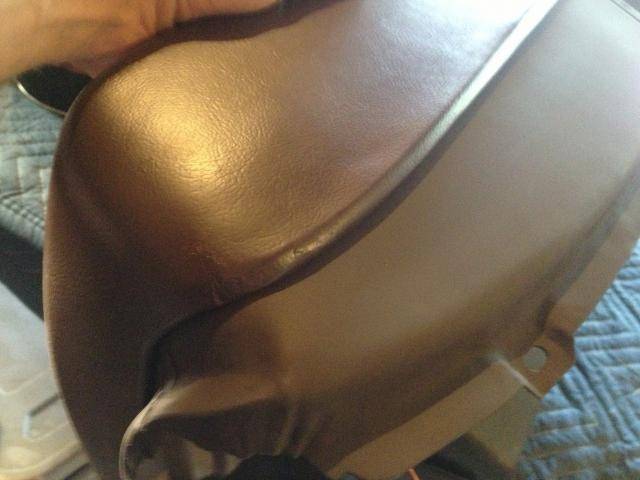

I didn't get around to pulling the speaker out of the box till late Saturday. (Saturday morning I hit the salvage yard and got a few things.) Took me about 10 seconds to figure out -This is not a bolt in replacement! After comparing and scratching my head a while I came up with a plan. I proceded to dissasemble the old speaker with a cutoff tool. I basically ended up using the old one as a mounting frame. Today I did the final trim and fit it together. The way they seat together there was about a 1/8 gap between the frames at the screws. I used rubber faucet washers to fill that so they would pull tight together without bending. I added some foam tape to the face for a nice seat to the dash. I then got some fabric, stretched it over and epoxied it to the outer edge. I then trimmed it about a quarter inch extra and glued that wrapping the edge. The cover is black, just looks brown in pic.

So I get the dash out and realize the speaker is toast - as apparently most of them are. I considered going to a dual 3.5 and either make a bracket or buy from the guy on here that makes them. Then I saw these RetroSound dual cone replacements. Anyway I went to Carlisle Friday and they had them. Figured buy it, speaker in hand, quick and easy install - no problem.... Before I continue on the speaker... gotta say Carlisle was great, but I need to plan for 2 days next year. My daughter went with me. She's getting her licence soon and enjoyed the cars. (she was taking pics of all the purple cars) We got to see the A's and E's and maybe 3/4s of the swap area. A few other bits and pieces and the day was over. With a little luck I may take the Duster and camp there next year.

I didn't get around to pulling the speaker out of the box till late Saturday. (Saturday morning I hit the salvage yard and got a few things.) Took me about 10 seconds to figure out -This is not a bolt in replacement! After comparing and scratching my head a while I came up with a plan. I proceded to dissasemble the old speaker with a cutoff tool. I basically ended up using the old one as a mounting frame. Today I did the final trim and fit it together. The way they seat together there was about a 1/8 gap between the frames at the screws. I used rubber faucet washers to fill that so they would pull tight together without bending. I added some foam tape to the face for a nice seat to the dash. I then got some fabric, stretched it over and epoxied it to the outer edge. I then trimmed it about a quarter inch extra and glued that wrapping the edge. The cover is black, just looks brown in pic.

Last edited:

I was hoping to install the dash today. Thought I had it ready till I had it in the car and looked at the connector for the vaccuum lines. There were 2 pins broke off in the connector. One was a blank, but the other needed to work. Don't know how I missed this. I had even tried to reinforce one of the other pins that was cracked, but still in place. So I carried the dash back in to my work table and figured out a solution.

I got this connector assortment and used the 2 small ones to make new pins. (you only get 2 of the small ones, so the one laying out in pic is actually lager than what I used) I used a utility knife to shave the barbs and the center tabs off. Chucked it in the drill and sanded round. Then drilled holes and tapped. Just move control so internal piece is out of the way before drilling. Used die to thread pins. The first one I tried at 6-32 but the die would wanted to twist the tube. By leaving the end barb on I was able to do them better at 8-32. I then used a little plastic epoxy on the thread and screwed them in. They seem to be more solid than the originals. Not sure how it seals them inside, so I'll have to wait till everything is together to see how well it functions.

I got this connector assortment and used the 2 small ones to make new pins. (you only get 2 of the small ones, so the one laying out in pic is actually lager than what I used) I used a utility knife to shave the barbs and the center tabs off. Chucked it in the drill and sanded round. Then drilled holes and tapped. Just move control so internal piece is out of the way before drilling. Used die to thread pins. The first one I tried at 6-32 but the die would wanted to twist the tube. By leaving the end barb on I was able to do them better at 8-32. I then used a little plastic epoxy on the thread and screwed them in. They seem to be more solid than the originals. Not sure how it seals them inside, so I'll have to wait till everything is together to see how well it functions.

Last edited:

Been working on the dash for awhile and finally got it installed Saturday. Removed everything and repainted it with Rustoleum Camoflage Earth Brown. This gave the flat look I wanted under the windshield. Then I rubbed the lower part with 0000 steel wool to bring it up to a 'matte' finish. Replaced the pad with one from a yard. Did some small crack repairs, mainly both front corners and painted with SEM Cordovan brown. Re-taped harness as needed, got a new radio from Pep Boys to go with the speaker from previous posting. Replaced the broken support wire for the glove box door and spent a couple hours bending the hinge to work right. Also replaced the duct hoses. Got everything hooked up/wired up that I could. Still need to get door switches and put the cluster back in as well as AC vent.

Started some parts re-work. I got a set of LCAs with tabs for the sway bar, but the shafts on them are bugered up a bit. So, dismantled both sets. Figured while on a roll I'd get the old bushing sleeves out of the extra set too. I read that the shafts usually come out fairly easy, but that did not happen. I found that turning them with a pipe wrench to break them loose and heating till rubber just started to burn then beating out with a hammer did the trick. As for the weld on washer meathod, that worked great. I did rip the first one off, because I used too small of a punch. By using a shaft that just made it through the back it took them out fairly easy without distorting the washer much and spread the load around the whole welded edge. Also I don't know how much difference it makes, but I knocked them out right after I welded them to take advantage of them being heated up.

I really LOVE what you are doing to this car!

I'm only able to work on mine once a week, and I am going with more modifications, however, your project is inspiring!

I'm only able to work on mine once a week, and I am going with more modifications, however, your project is inspiring!

Got some parts cleaned up last week . Getting everything washed, sun dried, and primed as soon as possible afterwards. All it takes is a little humidity and the surface rust kicks in pretty quick. Most of this stuff is actually painted already - more picks to come as I get it together.

I hammered out a few edges on the pan and cover, but overall they weren't bad. Also did a little straightening and welding on the K. I aint claiming to be a great welder, but they were just sloppy when they put these together. Some areas you could tell they intended to do a weld and either missed a section or blew a hole and moved on...I did not have a sway bar before. The area that the brackets will attach to was welded with the parts spread open. I had to cut apart, straighten and reweld.

Primed the LCAs and took up to my local garage to be pressed.

I hammered out a few edges on the pan and cover, but overall they weren't bad. Also did a little straightening and welding on the K. I aint claiming to be a great welder, but they were just sloppy when they put these together. Some areas you could tell they intended to do a weld and either missed a section or blew a hole and moved on...I did not have a sway bar before. The area that the brackets will attach to was welded with the parts spread open. I had to cut apart, straighten and reweld.

Primed the LCAs and took up to my local garage to be pressed.

Last edited:

-