Need to redo an intake bolt(oil leak) It is an edde. performer 318/360 Torq spec. are 25 ft. lbs correct? i dont want to mess it up Thanks.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Confirm torq. specs.

- Thread starter Roadart

- Start date

-

I know there is a torque spec but I have never used a torque wrench. Some of the fasteners are next to impossible to get a socket on. You need a torque adapter.

Had not thought about lack of space. OK thanks for the info.

A firm pull on a 6" long 3/8" drive Rachet is about the right torque. The middle ones are good with the box end of a standard combination wrench. Tighten in sequence from the center out and side to side a little at a time.

67Dart273

Well-Known Member

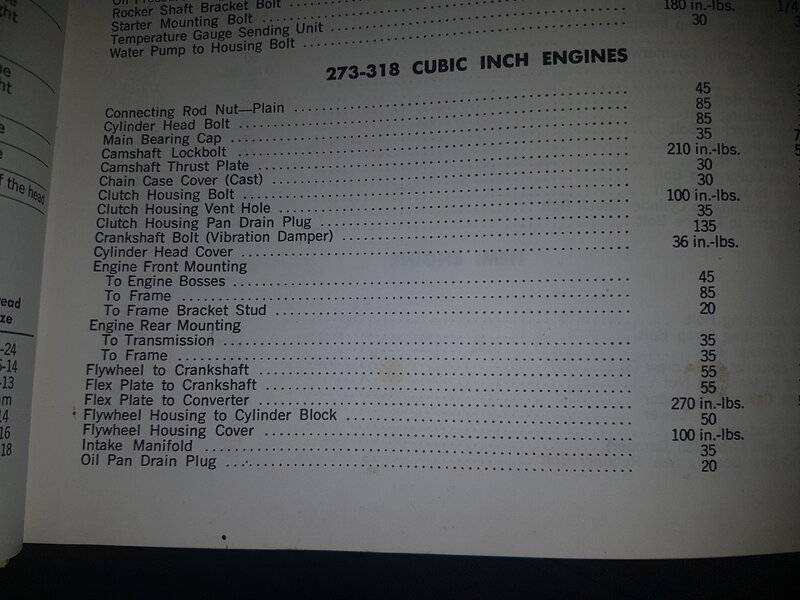

The torque specs are all in the back section of the service manuals, which you can download free from MyMopar. There are a few specs that are "famously" incorrect, like the smaller rocker bolts on some years. You can double check yourself by figuring out "what bolt" you have AKA 3 point is grade 5 and then looking up a grade 5 bolt torque on the internet. There are charts all over the place.

Some specs are "dry" and some are "oiled" with (usually) a specified weight and type of oil.

As said, I have never in my life torqued an intake. Tighten it a little at a time "cross" and don't get all muscle on it. A "standard" combo wrench does not take much pull to generate the right torque, even at my age (u4)

Some specs are "dry" and some are "oiled" with (usually) a specified weight and type of oil.

As said, I have never in my life torqued an intake. Tighten it a little at a time "cross" and don't get all muscle on it. A "standard" combo wrench does not take much pull to generate the right torque, even at my age (u4)

But: Not too big a pull unless you enjoy HelicoilsA firm pull on a 6" long 3/8" drive Rachet is about the right torque. The middle ones are good with the box end of a standard combination wrench.

I usually use two fingers

65TerrorCuda

Well-Known Member

Chilton shows 35 ft*lbs for 273/318/340 which is what I went off back in 1996

But then,

First time torqueing those skinny 273 intake bolts I turned around to put away my tools only to hear a deafening BANG as one of the bolt heads sheared off and hit the underside of the hood. Lucky my face wasn't right there.

I really wanted to redo that whole job over. Lol that sucked. That iron intake is a boat anchor

But then,

First time torqueing those skinny 273 intake bolts I turned around to put away my tools only to hear a deafening BANG as one of the bolt heads sheared off and hit the underside of the hood. Lucky my face wasn't right there.

I really wanted to redo that whole job over. Lol that sucked. That iron intake is a boat anchor

USAF Issue

dano

Evil Handy Man

There is a box end to 3/8 square adapter that works well as long as the wrench is perpendicular to the torque wrench. I did my Stealth in the car after a leak and just did my headers with it too.

You can buy 12 point box end to 3/8 square torque adapters but they cost more and you don't get the flexibility of using a open end or wrench length.

Mine is like this.

https://www.amazon.com/dp/B09D9PN4Q7/?tag=fabo03-20

You can buy 12 point box end to 3/8 square torque adapters but they cost more and you don't get the flexibility of using a open end or wrench length.

Mine is like this.

https://www.amazon.com/dp/B09D9PN4Q7/?tag=fabo03-20

67 Plymouth smallblock. 35lb/ft.

OK we are overthinking this snug is good cold, run it and re snug them. I have a PMEL certification from the USAF so basically no swivels or extentions allowed, but that is Aircraft. Tourk adapters are expensive for what they do. Need any more info let me know. Also to be a *** T wrenchs should be broken at in the environment used.THen the set pressure three times in each direction in the temperature they are used at. Drop it it needs re- calibration, that is Aircraft, dont worry about it you will be fine. I am sure I will get the arm chair commandoes from this. My shop did at leas a few thousand T wrench calibrations a year as the Avionics shop chief. every 90 days. Something you think is simple is not.

https://www.google.com/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&cad=rja&uact=8&ved=2ahUKEwj7-pKoxd35AhXhD1kFHWmJAVoQFnoECAYQAQ&url=https://www.robins.af.mil/Portals/59/documents/technicalorders/32B14-3-1-101.pdf&usg=AOvVaw1Rcg25BTlgPZKQ9vCJ0sM7

https://www.google.com/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&cad=rja&uact=8&ved=2ahUKEwj7-pKoxd35AhXhD1kFHWmJAVoQFnoECAYQAQ&url=https://www.robins.af.mil/Portals/59/documents/technicalorders/32B14-3-1-101.pdf&usg=AOvVaw1Rcg25BTlgPZKQ9vCJ0sM7

Last edited:

-