I seriously doubt it takes even 2hp to drive a solid blade fan. But you are correct. It does take "something".See, that's why I like electrics. When I don't need my fans, they're not running. Way more efficient without all that parasitic drag. My fans pretty much never run unless I'm stopped, going light to light in traffic, or it's 110°F. And even when it's 110° they shut off if I can sustain 35mph or so for more than a few minutes at a time.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cooling issue on highway

- Thread starter SlantedDart

- Start date

-

SlantedDart

Well-Known Member

Bottom line I think I have an air flow issue.. going to make a simple airdamn off the bottom core support. Something like a 68 camaro.. Yes all these hemis run “hot”. I have 2020 technology in a 1968 chassis with very little aero.. maybe some air deflection is in order. I know some guys are die hard Mechanical fan ride or die but it’s not possible in this situation. With enough airflow in the right spot I think it will be possible. Need hot air to Go out also. I’m missing a seal on the hood. Also a big deal on new cars is pwm fans.. I can do that also which probably will happen. Going to start with some air dams

MopaR&D

Nerd Member

Bottom line I think I have an air flow issue.. going to make a simple airdamn off the bottom core support. Something like a 68 camaro.. Yes all these hemis run “hot”. I have 2020 technology in a 1968 chassis with very little aero.. maybe some air deflection is in order. I know some guys are die hard Mechanical fan ride or die but it’s not possible in this situation. With enough airflow in the right spot I think it will be possible. Need hot air to Go out also. I’m missing a seal on the hood. Also a big deal on new cars is pwm fans.. I can do that also which probably will happen. Going to start with some air dams

Pull the fan and shroud and test with them off first before spending money and time adding stuff to your car that you might not need and might not solve your problem anyway...

Scamp Rhonda

Well-Known Member

Exactly, I have '72 Scamp with a 318 and a stock clutch fan. It runs great at about 185… no problem. I had '50 Buick with a 455 Buick engine and dual electric fans and puked coolant all the time from overheating. Bottom line for me is it was never engineered that way. So if does work for you, you got lucky. Also, one of my vehicles, I don't remember which, overheated on the freeway and the cause was rusty fins on the radiator that would fold shut at higher speeds. Your radiator is new so I would suspect there's to much stuff hanging on it to let enough air through it. Fans and a restrictive shroud maybe?Exactly, G3 Hemis weren't designed to run with mechanical fans except in trucks and those fans are gigantic. Just like our old carbed engines weren't designed to run with electric fans. It takes some work and know-how to get that stuff right, thermal management is no joke.

Yes, lots of modern cars use elec fans. But there is a big difference between these & our old iron monsters. New cars run 195* t/stats or higher. Our old stuff runs best with 180s. So elec fans on old cars would have to pull more heat out....

Had to go in and straighten out someone else's electric fan overheating build. That's why they came to me. Had to install the low profile, silent running non-flex manual 18" fan.

Low parasite loss, moves lots of air as it cuts the air not flexing the blades. Runs Quiet, keeping the engine cool without worry even on the hot days.

Simple Fix . . . without all the added electronics and headaches and worries if all the sudden it's going to overheat.

A mechanical fan with no clutch does not have “low parasitic drag”. The higher your RPM, the worse the parasitic loss gets. And at speeds where you don’t even need a fan.

Literally the worst thing about mechanical fans. At low RPM and low speed, when you need airflow from the fan the most, you have the least output from the fan. At high rpm and speed, when your literally don’t need the fan at all, it’s moving the most air. Which is why pretty much every new car runs electric fans.

Elec fans. Sigh. An elec fan that can pull as much air as my 7 blade, 19" mech fan, would need an enormous motor to drive it. Substantial parasitic loss. I do not see anything clever in moving from a reliable, stand alone, mech fan to a complicated elec fan that needs a controller or relay to run it along with heavy wiring.

Yeah? How many cfm does that fan blade move? And at what RPM’s?

Let’s see the specs so I can show you the electric fan that will do it.

I seriously doubt it takes even 2hp to drive a solid blade fan. But you are correct. It does take "something".

I bet you’re wrong. And remember, what it takes at idle and what it takes at 6k rpm are very different.

Yes, lots of modern cars use elec fans. But there is a big difference between these & our old iron monsters. New cars run 195* t/stats or higher. Our old stuff runs best with 180s. So elec fans on old cars would have to pull more heat out....

The factory thermostat on all of these A-body cars was a 195*F. Look it up.

New cars are harder to cool anyway. The engine compartments are tighter, the hp per cubic inch numbers are MUCH higher, and that means more heat with less metal to absorb and diffuse it.

[1] And lots of people use 180 [ or 160 ] thermostats in their old cars NOW. When these cars were made, the fuel had lead in it which cooled the combustion process & reduced the chance of detonation. No lead to day, cooler engine by whatever means, to reduce chances of detonation.

[2] New cars have much more alum in them than old cars [ look it up ]. Easier to cool because of it's greater thermal conductivity compared to CI.

[2] New cars have much more alum in them than old cars [ look it up ]. Easier to cool because of it's greater thermal conductivity compared to CI.

I might be wrong, but I don't have a choice. I don't have enough room for a clutch fan. I don't have enough $$$ for an electric fan. At least not right now.A mechanical fan with no clutch does not have “low parasitic drag”. The higher your RPM, the worse the parasitic loss gets. And at speeds where you don’t even need a fan.

Literally the worst thing about mechanical fans. At low RPM and low speed, when you need airflow from the fan the most, you have the least output from the fan. At high rpm and speed, when your literally don’t need the fan at all, it’s moving the most air. Which is why pretty much every new car runs electric fans.

Yeah? How many cfm does that fan blade move? And at what RPM’s?

Let’s see the specs so I can show you the electric fan that will do it.

I bet you’re wrong. And remember, what it takes at idle and what it takes at 6k rpm are very different.

The factory thermostat on all of these A-body cars was a 195*F. Look it up.

New cars are harder to cool anyway. The engine compartments are tighter, the hp per cubic inch numbers are MUCH higher, and that means more heat with less metal to absorb and diffuse it.

Uncle Bob

Shiny paint causes stress.

Same here. I'm pretty sure we both have essentially the same setup - IIRC you have TD mounts, I have elephant ears. The last time I measured mine I had trouble even finding an electric fan that will fit unless it was offset to the driver's side and then it was just a guess. So I use a fixed fan and shroud, and try to not panic when the gauge starts climbing. I'm still trying to solve it though.I might be wrong, but I don't have a choice. I don't have enough room for a clutch fan. I don't have enough $$$ for an electric fan. At least not right now.

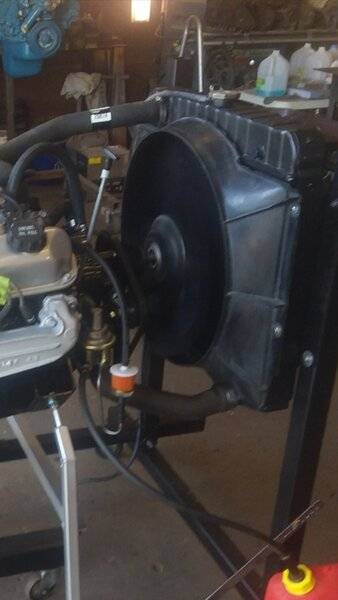

This is the 18" silent run fan, 3/4" away from the radiator, no shroud, aluminum radiator.

The blades don't flex, the design cuts the air instead of chopping it so they run quiet and don't rob extra power.

Tight quarters with the serpentine belt dress up kit that pushes everything forward, this fan cleared everything easily, and is keeping the big 440 with headers running cool. No Shroud.

$65.00 shipped in.

You can even see here the electric fan and shroud setup was actually rubbing the center of the aluminum serpentine water pump pulley in the tight quarters.

Got a nice job of machining down the aluminum serpentine pulley so the silent run fan would bolt up with the proper spacer.

As a mock up example here is the first silent run fan setup:

________________

For those who are curious about the the "Flex Fans".

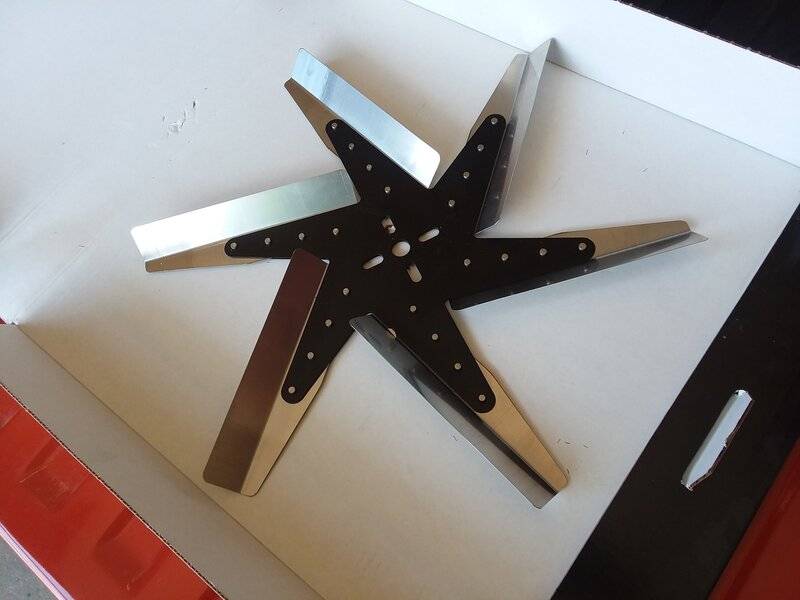

Here is a picture of one that is 18", makes lots of noise, robs power, and won't clear in the tight quarter situations like Elephant Ears, serpentine belt setups/dress ups, and just plain tight quarter layouts.

☆☆☆☆☆

The blades don't flex, the design cuts the air instead of chopping it so they run quiet and don't rob extra power.

Tight quarters with the serpentine belt dress up kit that pushes everything forward, this fan cleared everything easily, and is keeping the big 440 with headers running cool. No Shroud.

$65.00 shipped in.

You can even see here the electric fan and shroud setup was actually rubbing the center of the aluminum serpentine water pump pulley in the tight quarters.

Got a nice job of machining down the aluminum serpentine pulley so the silent run fan would bolt up with the proper spacer.

As a mock up example here is the first silent run fan setup:

________________

For those who are curious about the the "Flex Fans".

Here is a picture of one that is 18", makes lots of noise, robs power, and won't clear in the tight quarter situations like Elephant Ears, serpentine belt setups/dress ups, and just plain tight quarter layouts.

☆☆☆☆☆

mopowers

Well-Known Member

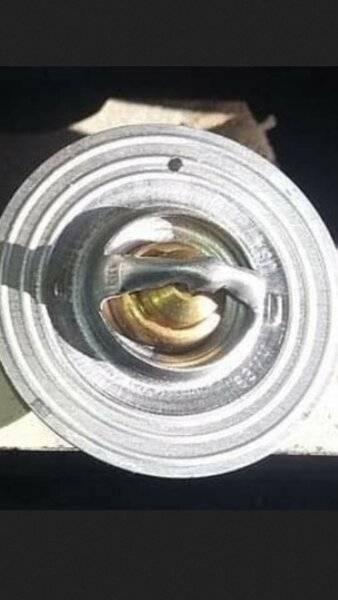

The factory thermostat on all of these A-body cars was a 195*F. Look it up.

Not quite. Out of curiosity, I looked it up. It seems to vary depending on the year.

Here's what the '66 Dodge FSM says:

'68 Plymouth FSM:

'69 Dodge FSM:

'73 Dodge FSM:

mopar head

DoD nuisance Alien/Squatch extermination team

Someone did a dyno test to see how much a solid fan robbed horsepower.I seriously doubt it takes even 2hp to drive a solid blade fan. But you are correct. It does take "something".

IIRC it was close to 20

I’m missing a seal on the hood.

I was going to ask if you had a hood to core support seal.

[1] And lots of people use 180 [ or 160 ] thermostats in their old cars NOW. When these cars were made, the fuel had lead in it which cooled the combustion process & reduced the chance of detonation. No lead to day, cooler engine by whatever means, to reduce chances of detonation.

[2] New cars have much more alum in them than old cars [ look it up ]. Easier to cool because of it's greater thermal conductivity compared to CI.

Just because a lot of people run 160's (flat out stupid in anything other than a drag only car) or 180's in their car's now doesn't mean a thing. I would wager a lot of them don't even understand that the thermostat has nothing to do with how hot the engine runs, it merely sets the low temp limit. Let alone understand basic thermodynamics.

I am well aware that new cars use more aluminum. But they also run higher exhaust temperatures, higher compression, ridiculously tightly packed engine compartments and typically use smaller grille openings for improved aerodynamics. There are a lot of factors, but in general new cars have much higher cooling requirements than our old stuff. They also almost exclusively use electric fans, because they're more efficient.

I might be wrong, but I don't have a choice. I don't have enough room for a clutch fan. I don't have enough $$$ for an electric fan. At least not right now.

Hey that's fine man, you do what you need to do. Lots of different situations and builds out there and there are good reasons for running either type of fan.

But, that doesn't mean that electric fans aren't far more efficient. I honestly don't care what someone runs, I'm just tired of the old "electric fans don't work" argument because its completely untrue. People set up bad systems and blame the fan for their poor execution.

This is the 18" silent run fan, 3/4" away from the radiator, no shroud, aluminum radiator.

The blades don't flex, the design cuts the air instead of chopping it so they run quiet and don't rob extra power.

Tight quarters with the serpentine belt dress up kit that pushes everything forward, this fan cleared everything easily, and is keeping the big 440 with headers running cool. No Shroud.

$65.00 shipped in.

View attachment 1715953335

You can even see here the electric fan and shroud setup was actually rubbing the center of the aluminum serpentine water pump pulley in the tight quarters.

View attachment 1715953334

Got a nice job of machining down the aluminum serpentine pulley so the silent run fan would bolt up with the proper spacer.

View attachment 1715953337

As a mock up example here is the first silent run fan setup:

View attachment 1715953338

________________

For those who are curious about the the "Flex Fans".

Here is a picture of one that is 18", makes lots of noise, robs power, and won't clear in the tight quarter situations like Elephant Ears, serpentine belt setups/dress ups, and just plain tight quarter layouts.

View attachment 1715953339

☆☆☆☆☆

First, you left off the most important part- How many CFM does it pull, and what is it's output at different RPMS? If you don't know that, you can't argue it's a better fan.

Second, running without a shroud is terribly inefficient. Shrouds increase the amount of air your fan can move and pull it through the radiator where it is doing the most good.

Third, those thin sheetmetal blades absolutely flex. Maybe they flex less than the more standard flex fan design, but they 100% still flex. That's why they're riveted on. If flex was not part of the design they'd be solid blades instead of a thin blade riveted to a more solid base.

And finally, if your electric fan rubbed you chose the wrong electric fan. That's not the fault of electric fans in general. I run a serpentine belt system on my Duster with my electric fans and have no interference issues.

Not quite. Out of curiosity, I looked it up. It seems to vary depending on the year.

Here's what the '66 Dodge FSM says:

View attachment 1715953340

View attachment 1715953341

'68 Plymouth FSM:

View attachment 1715953348

'69 Dodge FSM:

View attachment 1715953347

'73 Dodge FSM:

View attachment 1715953351

Well you got me. All of my 318 cars had 195's in them, I probably shouldn't have assumed they were factory just because the parts houses list them as the stock replacement. Thanks for pulling that stuff up.

Can't argue with success, when a simple solution keeps an engine running cool.

Happy Motoring

☆☆☆☆☆

Happy Motoring

☆☆☆☆☆

Don't let the facts get in the way of a good story:

- some years ago, Hayden or Flex-a-Lite or one of the fan companies had flow figures on their website. A 19" seven blade mech fan pulled 6000+ cfm. Have not seen an elec fan get close to that.

- newer cars have generally smaller engines. So less coolant to cool than say a 440 [ 7.2L ], smaller fan work ok.

- newer cars using elec fans also have the luxury of detonation sensors; just pull out some timing if that small fan cannot stop the pinging. Our old iron doesn't have that ability. Therefore, the cooling system [ & fan ] needs to be capable of handling the worst case scenario. Not a job for a low output elec fan.

- newer cars run higher compression. That actually lowers temp, not raises it.

- there are going to be power losses in the drivetrain before the car moves. Losses from the alt, trans, p/s pump, & fan, etc.

- some years ago, Hayden or Flex-a-Lite or one of the fan companies had flow figures on their website. A 19" seven blade mech fan pulled 6000+ cfm. Have not seen an elec fan get close to that.

- newer cars have generally smaller engines. So less coolant to cool than say a 440 [ 7.2L ], smaller fan

- newer cars using elec fans also have the luxury of detonation sensors; just pull out some timing if that small fan cannot stop the pinging. Our old iron doesn't have that ability. Therefore, the cooling system [ & fan ] needs to be capable of handling the worst case scenario. Not a job for a low output elec fan.

- newer cars run higher compression. That actually lowers temp, not raises it.

- there are going to be power losses in the drivetrain before the car moves. Losses from the alt, trans, p/s pump, & fan, etc.

Ironracer

Gearhead

My 340 runs 185 in Tampa. At a light it creeps up bout 5 more, but goes back down when the air flow comes .What temp are you expecting? My LA runs at 192/197 all day in the central Florida heat.

Jarlaxle

Well-Known Member

Yes, you do. The modern Hemis are DESIGNED to run hot. My Challenger ran 200-210 highway and 210-225 in traffic. Even in the dead of winter, once it warmed up it NEVER ran below 200.I’d like it to run under 180 ish so my fans are not on for highway runs. Dont want the fan on for 30 min constantly. I can adjust the on/ off but I don’t want this thing to be at 200 on the city streets

Don't let the facts get in the way of a good story:

- some years ago, Hayden or Flex-a-Lite or one of the fan companies had flow figures on their website. A 19" seven blade mech fan pulled 6000+ cfm. Have not seen an elec fan get close to that.

But at what RPM was that 6,000 CFM figure? Was it at idle? 3,000 RPM? 6,000 RPM? Clearly that matters. How much does that fan move at idle? Because idling in traffic with no air moving through the radiator other than what the fan is pulling is the worst case situation.

The Ford Contour fans on my Duster pull 3,500 cfm on low speed and can move 5,000 cfm on high speed. Which means my fans will move 5k cfm when I'm at idle at a dead stop.

99% of the time only the low speed on my fans is actuated. The only time the high speed on my fans has been activated is the few times when I was caught in traffic in 105°F+ temperatures, once when I was stuck in traffic for a good half hour in 110°F temps. Car never overheated. So I would argue that the majority of builds don't even need a 6,000 cfm fan.

However, there are NUMEROUS threads on this board about guys trying to run a standalone electric fan that moves less than 3,500 cfm, and complaining about not being able to keep the car cool. And that's my point about electric fans, because there are plenty of people that try to put together a stand alone electric fan system with a fan that doesn't move enough cfm to be a stand alone fan. Clearly in most situations my 3,500 cfm fans are enough, and depending on your build and driving habits some folks could probably get away with less. But there are some really expensive SPAL and other fans that only put out about 2,500 cfm which for a lot of builds will not be enough.

But, But, But . .

Simple is Good

Simple is Good

Is it?

Flex Fans:Are they dangerous??

*MUST READ*--Flex Fan Danger--Be very careful working on old cars

And yeah, how many CFM does your fan move at idle? Still waiting.

As long as you are happy with your electric fan and box shroud setup that is fine with me.

Others on here like to see simple setups that work and keep them running cool.

Others on here like to see simple setups that work and keep them running cool.

As long as you are happy with your electric fan and box shroud setup that is fine with me.

Others on here like to see simple setups that work and keep them running cool.

I'm SUPER happy with my electric fans, and they don't have a "box shroud" because I use OEM fans. They outperform every mechanical fan I've run (which isn't as simple as saying they move the most CFM either).

An electric fan system isn't that complicated. The electric fan(s), some kind of controller which can be as simple as a thermostatic switch, and a relay for power. This is my entire set up

Ford Contour electric fans $142

Dorman 620-104 Dorman Electric Fans | Summit Racing

Dakota Digital controller w/ relay and harness $138 (this is a newer version of what I have, the old one is discontinued)

Dakota Digital PAC-2800BT Dakota Digital Electronic Fan Controllers with Bluetooth | Summit Racing

Extra relay $31 (needed for the two, dual speed fans)

Dakota Digital RLY-3 Dakota Digital Relays with Wiring Sockets | Summit Racing

I hate wiring. Hate it. If I can wire up a relay system for dual speed, dual electric fans, well, it's not that hard.

And yeah, simple can be inferior too. How many CFM does your fan move at idle? If you can't answer that, how are you in a position to make recommendations?

Jarlaxle

Well-Known Member

Junkyard and a tape measure. There are dozens of sizes available.I might be wrong, but I don't have a choice. I don't have enough room for a clutch fan. I don't have enough $$$ for an electric fan. At least not right now.

The blades certainly flex...and I wonder what that Chinese fan might do at 7500rpm. (I'd expect nothing good.)This is the 18" silent run fan, 3/4" away from the radiator, no shroud, aluminum radiator.

The blades don't flex, the design cuts the air instead of chopping it so they run quiet and don't rob extra power.

Tight quarters with the serpentine belt dress up kit that pushes everything forward, this fan cleared everything easily, and is keeping the big 440 with headers running cool. No Shroud.

$65.00 shipped in.

View attachment 1715953335

You can even see here the electric fan and shroud setup was actually rubbing the center of the aluminum serpentine water pump pulley in the tight quarters.

View attachment 1715953334

Got a nice job of machining down the aluminum serpentine pulley so the silent run fan would bolt up with the proper spacer.

View attachment 1715953337

As a mock up example here is the first silent run fan setup:

View attachment 1715953338

________________

For those who are curious about the the "Flex Fans".

Here is a picture of one that is 18", makes lots of noise, robs power, and won't clear in the tight quarter situations like Elephant Ears, serpentine belt setups/dress ups, and just plain tight quarter layouts.

View attachment 1715953339

☆☆☆☆☆

Don't let the facts get in the way of a good story:

- some years ago, Hayden or Flex-a-Lite or one of the fan companies had flow figures on their website. A 19" seven blade mech fan pulled 6000+ cfm. Have not seen an elec fan get close to that.

- newer cars have generally smaller engines. So less coolant to cool than say a 440 [ 7.2L ], smaller fanwork ok.

- newer cars using elec fans also have the luxury of detonation sensors; just pull out some timing if that small fan cannot stop the pinging. Our old iron doesn't have that ability. Therefore, the cooling system [ & fan ] needs to be capable of handling the worst case scenario. Not a job for a low output elec fan.

- newer cars run higher compression. That actually lowers temp, not raises it.

- there are going to be power losses in the drivetrain before the car moves. Losses from the alt, trans, p/s pump, & fan, etc.

I drove vehicles that ran 220 degrees with no knock sensors.

Electric Fan camp > 2.

Manual Belt Drive Fan camp > 14.

Popular opinion is siding with the Ma Mopar Crowd.

Ma Mopar did it right, right from the start.

Manual Belt Drive Fan camp > 14.

Popular opinion is siding with the Ma Mopar Crowd.

Ma Mopar did it right, right from the start.

-