I am running 2 660 center squirters on a tunnel ram. I am wondering at what throttle position do these carbs run on idle circuit vs transfer slots vs main jet. I have a cruise RPM of 2400 but looking at the spark plugs, it appears it is running lean. I am getting great fuel mileage, but I am concerned with the mixture. Idle screws were 1 1/4 turns out, idles and starts great. It also was 5 hours of driving in high 90 deg / Low 100 deg temps and sustained RPM. The coolant temp stayed mostly 190-200 deg for the trip, climbing to 210 at stops. I am not sure if idle mixture adjustment, more transfer slot (or less) or more jet. Unfortunately I do not remember the amount of transfer slot or what jets are in it at the moment. Engine is a mild, lower compression 440 with a Hughes Whiplash 440 cam. Converter is 2400 stall B&M, rear gear for the trip is 2.94.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cruise Seems Lean

- Thread starter 71GSSDemon

- Start date

-

MomsDuster

Well-Known Member

I’m no expert but, I’m willing to bet the experts will want pictures of the plugs. Does it surge at cruise?

I’m no expert but, I’m willing to bet the experts will want pictures of the plugs. Does it surge at cruise?

Thanks Mark. How are your 750's working?

The only surge I noticed was just before home, so at the hottest temps. I can pull plugs later and get pics. They are E3 plugs and I have never used them before. The combustion side of the plugs are black with deposits, the electrode side is gray in color on the 2 I pulled. I didn't change the tune after changing the gears from 3.91. It is noticeably different as cruise RPM is different and starting from a stop has a stumble whereas it didn't before, but I assumed that would happen.

MomsDuster

Well-Known Member

Mine's running pretty good, get 14mpg Hwy with 3.23’s. Haven’t put many miles on it yet as it’s been down for a few months. Doing a radical change to suspension that will probably require a slight change in the tune, but that’s a whole other thread LOL. Hopefully @yellow rose will chime in. He helped me tremendously on getting mine squared away.

Yup. That's the big clue its too lean!Does it surge at cruise?

Throttle position and load determine when the main circuits provide the bulk of the fuel into the airstream.

There has to be enough throttle opening and rpm that the air velocity creates a strong low pressure in the boosters.

2400 rpm at 30 mph might not produce enough load (wind resistance mostly) to the car movement to neccessitate much throttle opening.

2400 rpm at 65 mph probably will have enough resistance to the car moving that it does require enough throttle to bring on the mains.

Hesitation from a full stop is not related to the mains. If it happens with slow opening, then its "idle" circuit.

Yup. That's the big clue its too lean!

Throttle position and load determine when the main circuits provide the bulk of the fuel into the airstream.

There has to be enough throttle opening and rpm that the air velocity creates a strong low pressure in the boosters.

2400 rpm at 30 mph might not produce enough load (wind resistance mostly) to the car movement to neccessitate much throttle opening.

2400 rpm at 65 mph probably will have enough resistance to the car moving that it does require enough throttle to bring on the mains.

Hesitation from a full stop is not related to the mains. If it happens with slow opening, then its "idle" circuit.

I am running 2400-2500 at 65-70mph which is where I was cruising at. I wonder if it is a strange stack up lean condition at that specific RPM. I do have 2.94 gears right now. Just to experiment (in a safe controlled environment of course) ran up to 4000rpm in top gear just after the surge I noticed. Engine temp dropped down from 200 to 190. Not sure what speed I was traveling, not passed the 55mph I am sure, but it definitely was dumping more fuel. So, that said, how do I richen up the 2400 ish rpm? or is a gear change needed to bring the carbs into a happier place?

512Stroker

We are all here because we are not all there.

It most likely cooled down because at 4000 rpm you are spinning the water pump much faster. This is why most Hot Rodders will try to find a pulley ratio set that will overdrive the water pump to increase flow thru the cooling system and spin the fan faster for an increase in air flow.I am running 2400-2500 at 65-70mph which is where I was cruising at. I wonder if it is a strange stack up lean condition at that specific RPM. I do have 2.94 gears right now. Just to experiment (in a safe controlled environment of course) ran up to 4000rpm in top gear just after the surge I noticed. Engine temp dropped down from 200 to 190. Not sure what speed I was traveling, not passed the 55mph I am sure, but it definitely was dumping more fuel. So, that said, how do I richen up the 2400 ish rpm? or is a gear change needed to bring the carbs into a happier place?

I'll assume your 55 mph comment is a legal disclaimer.

The fact that you could increase throttle (especially without going to an easier gear) suggests the jetting is not too lean.

Generally with a lean surge on the main jets, the only solution is to slow down. If thats what you meant, then yes try one size larger jets on each primary.

If its the other scenario (not jets) then it seems that its the overlap from idle/transition to mains that could use some fattening.

and/or possibly a hair less timing at that rpm.

Since there is a little hesitation from stop, maybe the first experiment is to slightly richen and possibly extend the idle/transition mix. For that I'd start with trying slightly more restricted idle air bleeds. See how that works, especially for the off idle hesitation.

The fact that you could increase throttle (especially without going to an easier gear) suggests the jetting is not too lean.

Generally with a lean surge on the main jets, the only solution is to slow down. If thats what you meant, then yes try one size larger jets on each primary.

If its the other scenario (not jets) then it seems that its the overlap from idle/transition to mains that could use some fattening.

and/or possibly a hair less timing at that rpm.

Since there is a little hesitation from stop, maybe the first experiment is to slightly richen and possibly extend the idle/transition mix. For that I'd start with trying slightly more restricted idle air bleeds. See how that works, especially for the off idle hesitation.

512Stroker

We are all here because we are not all there.

MattaxI'll assume your 55 mph comment is a legal disclaimer.

The fact that you could increase throttle (especially without going to an easier gear) suggests the jetting is not too lean.

Generally with a lean surge on the main jets, the only solution is to slow down. If thats what you meant, then yes try one size larger jets on each primary.

If its the other scenario (not jets) then it seems that its the overlap from idle/transition to mains that could use some fattening.

and/or possibly a hair less timing at that rpm.

Since there is a little hesitation from stop, maybe the first experiment is to slightly richen and possibly extend the idle/transition mix. For that I'd start with trying slightly more restricted idle air bleeds. See how that works, especially for the off idle hesitation.

I am not trying to muck up the water here.

Do the Holley 660's have removable air bleeds?

I seem to remember the pair I had years back did not.

I'll assume your 55 mph comment is a legal disclaimer.

The fact that you could increase throttle (especially without going to an easier gear) suggests the jetting is not too lean.

Generally with a lean surge on the main jets, the only solution is to slow down. If thats what you meant, then yes try one size larger jets on each primary.

If its the other scenario (not jets) then it seems that its the overlap from idle/transition to mains that could use some fattening.

and/or possibly a hair less timing at that rpm.

Since there is a little hesitation from stop, maybe the first experiment is to slightly richen and possibly extend the idle/transition mix. For that I'd start with trying slightly more restricted idle air bleeds. See how that works, especially for the off idle hesitation.

Yes, 55mph was legal talk. Yes, at any speed it will accelerate very well. Stab the throttle and there is a stumble, which normally I would think of adding a larger squirter, but these center squirters are new to me. If I ease into it (or post split second stumble) it pulls very hard to 6000 rpm at which point I let out or shift, etc.

For the "slightly more restrictive air bleeds", is that where people are using the fine wire sizes to test? Anyone have pictures as to doing this? I haven't gotten this far into fine tuning. I never had this issue when running the 3.91s. More RPM at cruise but lower speed.

I don't know. I assume not unless they've been modified.Mattax

I am not trying to muck up the water here.

Do the Holley 660's have removable air bleeds?

I seem to remember the pair I had years back did not.

Dealing with carbs that have choke towers, I'm lazy and stick wire of various diameters into the air bleeds.

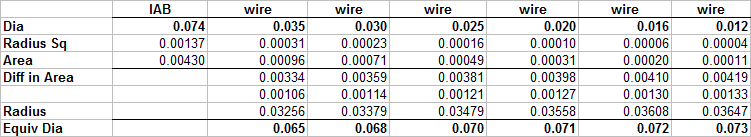

Did it so much I made a little spread sheet chart for IAB and MAB diameter equivalents with different size wires.

My gut tells me it is an odd transition rpm that happens to be where cruise is and is lean. I got great mileage, but it was running hot, and was very hot outside - which I think combined and made additional issues. I like the gear as several of the shows I wish to attend are about an hour or more away on freeway. If I change back to the 3.91 to add rpm and get into the main jets more, then my cruise speed will be greatly reduced. I would like to richen it up at this spot and keep what I have if possible. I have plenty of fuel available with increased throttle position. I also would like to keep the tunnel ram, but I have an Edelbrock torquer 440 intake and 850dp on the shelf. I am hoping I didn't hurt the engine on this trip and want to keep from doing any damage.

512Stroker

We are all here because we are not all there.

That may be pretty advanced for the OPI don't know. I assume not unless they've been modified.

Dealing with carbs that have choke towers, I'm lazy and stick wire of various diameters into the air bleeds.

Did it so much I made a little spread sheet chart for IAB and MAB diameter equivalents with different size wires.

I am glad we have you to walk him through the procedures.

In desperation I've stripped and cut whatever was handy.

At this point I have several small rolls of piano wire. That's not the easiest to work with but is easy to purchase in specific diameters.

With softer wire I stick it in one bleed and then run it up over the choke tower (if present) then under the air cleaner gasket.

That way it can't go any where and is easier to keep track of.

Actually what I really prefer is bending one for each pair. That takes a little trial and error.

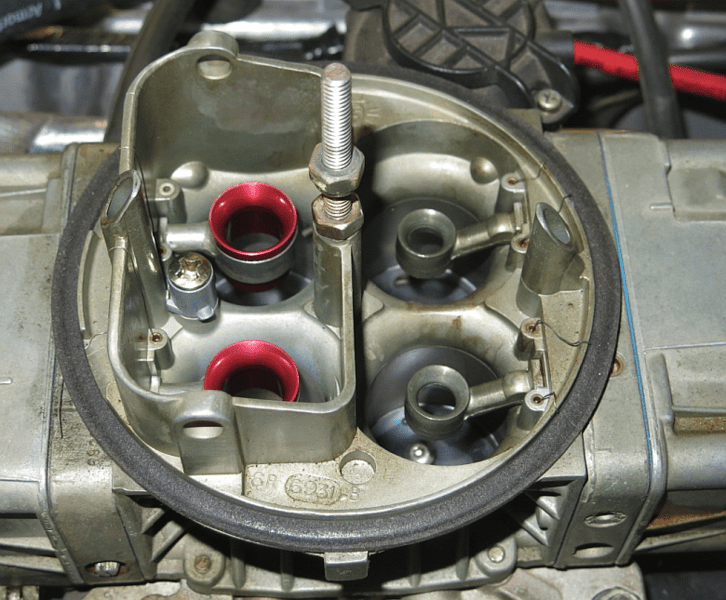

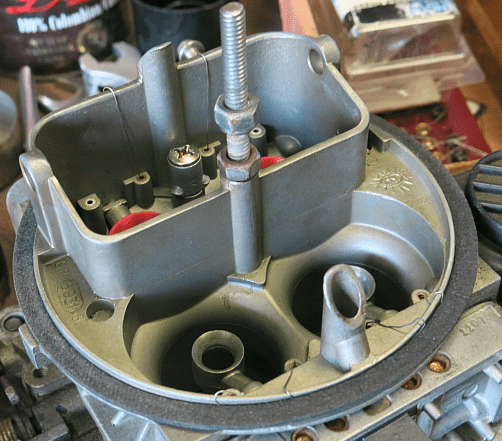

Yes I have a picture of the current frankensteind 3310 on my car.

In this pic the wires are in the MABs and the SIAB only. I actually pressed in a different PIAB in this one.

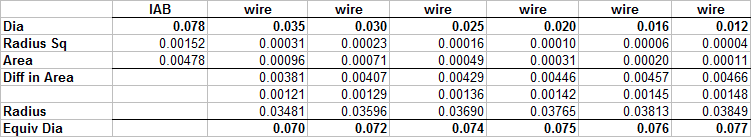

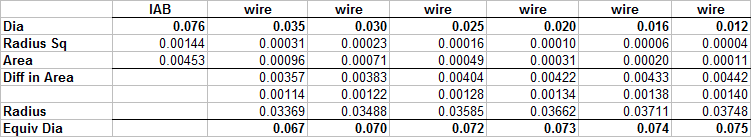

Cheat sheet for a few IAB sizes.

So if a carb has .076 IABs, and .025" wire is placed in each one, they will be equivallent of .072 IABs.

At this point I have several small rolls of piano wire. That's not the easiest to work with but is easy to purchase in specific diameters.

With softer wire I stick it in one bleed and then run it up over the choke tower (if present) then under the air cleaner gasket.

That way it can't go any where and is easier to keep track of.

Actually what I really prefer is bending one for each pair. That takes a little trial and error.

Yes I have a picture of the current frankensteind 3310 on my car.

In this pic the wires are in the MABs and the SIAB only. I actually pressed in a different PIAB in this one.

Cheat sheet for a few IAB sizes.

So if a carb has .076 IABs, and .025" wire is placed in each one, they will be equivallent of .072 IABs.

Last edited:

512Stroker

We are all here because we are not all there.

Post some pic's of the plugs.My gut tells me it is an odd transition rpm that happens to be where cruise is and is lean. I got great mileage, but it was running hot, and was very hot outside - which I think combined and made additional issues. I like the gear as several of the shows I wish to attend are about an hour or more away on freeway. If I change back to the 3.91 to add rpm and get into the main jets more, then my cruise speed will be greatly reduced. I would like to richen it up at this spot and keep what I have if possible. I have plenty of fuel available with increased throttle position. I also would like to keep the tunnel ram, but I have an Edelbrock torquer 440 intake and 850dp on the shelf. I am hoping I didn't hurt the engine on this trip and want to keep from doing any damage.

Try to keep them in order by cylinder.

Get the camera angle where you can see down in the plug while showing side angle of the ground strap so we can read the timing make on the strap.

Thanks. Hopefully sticking some wires in the IABs is something he is willing to test.That may be pretty advanced for the OP

I am glad we have you to walk him through the procedures.

512Stroker

We are all here because we are not all there.

Dam Boy!In desperation I've stripped and cut whatever was handy.

At this point I have several small rolls of piano wire. That's not the easiest to work with but is easy to purchase in specific diameters.

With softer wire I stick it in one bleed and then run it up over the choke tower (if present) then under the air cleaner gasket.

That way it can't go any where and is easier to keep track of.

Actually what I really prefer is bending one for each pair. That takes a little trial and error.

Yes I have a picture of the current frankensteind 3310 on my car.

In this pic the wires are in the MABs and the SIAB only. I actually pressed in a different PIAB in this one.

View attachment 1715748597

Cheat sheet for a few IAB sizes.

View attachment 1715748598

View attachment 1715748599

View attachment 1715748600

So if a carb has .076 IABs, and .025" wire is placed in each one, they will be equivallent of .072 IABs.

You have put some thought into this.

I knew the right man was on the job.

First time I did this a coworker (and former stock eliminater) showed me. It was about 10 PM at night and the car wasn't going to go up the hills for me to get home if we didn't fix it. We'll skip the story of how we got into this situation but involved some typical carb modifictions. I know his wife wasnt going to be happy if I had to sleep on the couch. LOL.Dam Boy!

You have put some thought into this.

I knew the right man was on the job.

Wasn't til much later I really understood why it worked and what it does.

Post some pic's of the plugs.

Try to keep them in order by cylinder.

Get the camera angle where you can see down in the plug while showing side angle of the ground strap so we can read the timing make on the strap.

Thanks. Hopefully sticking some wires in the IABs is something he is willing to test.

I will get the plugs out later today (maybe lunch?) and post pics. I am willing to try/test whatever is needed. I do failure analysis on engines (new, modern fuel injected overhead cam, etc) for a living, so I am comfortable with most tests, I am learning more on the testing/tuning, etc on our carb engines.

I don't think 210 is unreasonable or anything to worry about in those conditions as long as it stablizes. if it keeps climbing and/or stays above 230, then I'd be concerned. Heck there's plenty of engines that came with 195 deg thermostats.but it was running hot, and was very hot outside - which I think combined and made additional issues

I think its totally doable. It may be take some testing (trial and error). It also may need a hair less timing. That would probably be just a an adjustment on the vacuum advance. On the road race engines, the guys are running less timing than the drag race guys.* Big difference in engine temps between running an engine for a short burst versus one thats running for hours and hours. Its one reason the factory timing was on the slightly conservative side. They wanted to cover the worst case conditions while still providing good power and milage.I would like to richen it up at this spot and keep what I have if possible.

*These guys all use the same tuner. Tim Herron (All time racing), Ott (RiP) and Hagstrom, Mike Ritz (Team Starfish racing tribute) are three I know of.

Scody21

Just send it

E3 spark plugs only belong in the round file cabinet on the side of the work bench. AkA the trash. They cause more problems than there worth. YR will tell ya to get some champions, put them in, warm her up and then go stand on the gas for 10 minutes, pull the plugs and send a pic...

Also, if you ever have the chance of YR taking your car for a drive, I’d recommend just standing there and not going. He’s a maniac.... just sayin

Also, if you ever have the chance of YR taking your car for a drive, I’d recommend just standing there and not going. He’s a maniac.... just sayin

Last edited:

E3 spark plugs only belong in the round file cabinet on the side of the work bench. AkA the trash. They cause more problems than there worth. YR will tell ya to get some champions, put them in, warm her up and then go stand on the gas for 10 minutes, pull the plugs and send a pic...

I haven't had any run issues with the E3, but I can try something else. I am most concerned with the RPM I was running for the 5 hours on the road as that would be typical cruise rpm. This is where the plugs are at currently.

yellow rose

Overnight Sensation

I’m going to disagree on the engine temperature. At least a bit. 200 is just too hot for this stuff. I don’t know your compression ratio or cam timing or even what plug you are using but that is way too hot for me.

This isn’t an emissions deal so for me, power is everything and that’s too hot. Engine heat will make them detonate. So that lean surge may have been from the engine temp getting up to the point where the fuel was vaporized so much from engine heat it didn’t pull enough heat out of the air stream as it heads for the chamber. That raises the inlet air temperature and you can get a lean surge or even detonation.

Of course, you can get the engine too cool and get into other issues, most of which can be cleaned up with annular boosters. Which if you like to tinker with this stuff changing boosters is relatively easy if you have the tool. It’s about 200 bucks for the boosters and banjos. I’m not saying you need that. But it’s an option if you can get the engine temp down.

Pictures of the plugs and some specs would help.

BTW, in the /6 forum, @RustyRatRod has a thread outlining his tune up with a higher than “normal” compression ratio and how engine temperature affected his tune up and such. Maybe he will see this and add his 20 cents. His thread is worth reading.

This isn’t an emissions deal so for me, power is everything and that’s too hot. Engine heat will make them detonate. So that lean surge may have been from the engine temp getting up to the point where the fuel was vaporized so much from engine heat it didn’t pull enough heat out of the air stream as it heads for the chamber. That raises the inlet air temperature and you can get a lean surge or even detonation.

Of course, you can get the engine too cool and get into other issues, most of which can be cleaned up with annular boosters. Which if you like to tinker with this stuff changing boosters is relatively easy if you have the tool. It’s about 200 bucks for the boosters and banjos. I’m not saying you need that. But it’s an option if you can get the engine temp down.

Pictures of the plugs and some specs would help.

BTW, in the /6 forum, @RustyRatRod has a thread outlining his tune up with a higher than “normal” compression ratio and how engine temperature affected his tune up and such. Maybe he will see this and add his 20 cents. His thread is worth reading.

Awsome. A long time ago I was involved with design validation testing for airbags. My coworker mentioned above was a mechanical tech there, and I paid the machine shop to turn the air bleed restrictions which eventually went into that 3310 pictured above.I do failure analysis on engines (new, modern fuel injected overhead cam, etc) for a living, so I am comfortable with most tests, I am learning more on the testing/tuning, etc on our carb engines.

A few rules of thumb.

The "idle" circuit can be extended into higher throttle opening without changing the mixture by changing the IFR and the IAB proportionally. In other words a larger or smaller pair will get the same ratio but choke off flow later or ealier.

The main airbleeds in combination with the "emulsion holes" can effect the initiations of the main circuit. Increasing or decreasing the main airbleeds does not always do what you expect in this regard. Big changes the main jets may require a matching adjustment in MAB.

Can read the info in this post and the second post for more about these relationships.

Scody21

Just send it

I don't think 210 is unreasonable or anything to worry about in those conditions as long as it stablizes. if it keeps climbing and/or stays above 230, then I'd be concerned. Heck there's plenty of engines that came with 195 deg thermostats.

I think its totally doable. It may be take some testing (trial and error). It also may need a hair less timing. That would probably be just a an adjustment on the vacuum advance. On the road race engines, the guys are running less timing than the drag race guys.* Big difference in engine temps between running an engine for a short burst versus one thats running for hours and hours. Its one reason the factory timing was on the slightly conservative side. They wanted to cover the worst case conditions while still providing good power and milage.

*These guys all use the same tuner. Tim Herron (All time racing), Ott (RiP) and Hagstrom, Mike Ritz (Team Starfish racing tribute) are three I know of.

It’s been a while since I was at Sonoma or Laguna watching the classics. I will be later this summer and I’m going to really check out the road race AAR and T/A’s while in the paddock. These were 340’s that were de-stroked to 302’s. Not sure if the cars ran a high volume water pump or larger radiator. Not seen a B.B. road race motor, but a race boat yeah and similar timing setup.

-