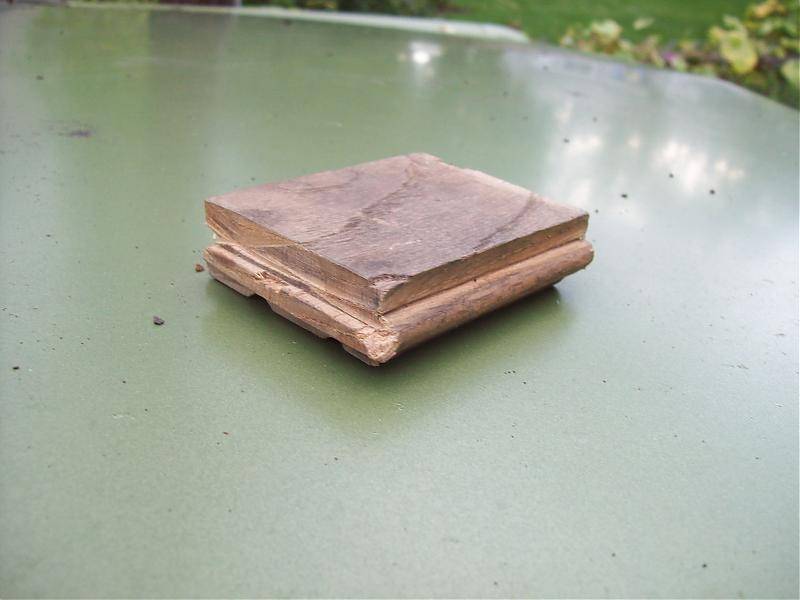

Hey Guys!!! I had answered a post titled "Useful Tools" and put in my 2 cents about a tool I made to remove drip rail mouldings. A couple of people asked to see it so I thought I would post it for all to see. It is simple as you can see in the pictures. It is actually just a piece of oak hardwood flooring with the factory tongue on one end and a bevel cut on half of the other end. In the pictures you can see it in action. You just put the tongue under the drip rail near the small corner piece and lever it to pop off the moulding from underneath. As you go around the curve, the space between the moulding and the rain seal channel gets bigger, you simply flip the "tool" around and use the beveled end to keep the distance close to the moulding. It takes me about 2 minutes a side to pop off a set with this tool, and since it is wood it does not damage the moulding in any way. Because it is oak it stands up to the metal better than wood of another species, but it is not hard enough to damage the moulding like a metal tool would do. The best thing about this tool is that it can be "sharpened" by cleaning up the tongue with a quick trip through the mitre saw or other tool, and also they're free. Just go to the Home Depot nearest you and ask for a sample of hardwood flooring. Just be sure to get a piece with the tongue on the end of the piece. As you can see, mine has been used many times and it's been sharpened a couple of times as well. It's time for me to make another, but this time I am going to leave it a little longer for better leverage. I might also pre-sharpen it to make the tongue just a little longer. Just a little homemade gadget to make life easier. Enjoy, all. Geof

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Drip Rail Removal Tool

- Thread starter cosgig

- Start date

-

71produster

Well-Known Member

Thanks for the tip!!

beastie340

Well-Known Member

Remember those bottle openers, the one you had to have before twist offs. Just wrap tape around the part that usually sits on top the cap hook the part that goes under the cap on the bottom of the trim, start at the back and work forward an inch at a time, then lift off trim. done it that way for years.

Used a paint stick once too, the oak flooring trick looks good though I'll try it next time ,I've got some scraps here somewhere.

Used a paint stick once too, the oak flooring trick looks good though I'll try it next time ,I've got some scraps here somewhere.

clhyer

Well-Known Member

- Joined

- Feb 24, 2007

- Messages

- 3,734

- Reaction score

- 320

Thanks for the tip and pics! I will have to make one for future use.

C

Speaking of useful but cheap or homemade... I find my wooden sawhorses to be very useful. I had the car body sitting on them over last winter while I was doing the trunk floor, I made them the same height as my p/u tailgate, I can actually make a pretty long worktable using two horses and the truck, I throw an old door on them to make a quick worktable wherever I want it set up & a 100 other uses!

C

C

Speaking of useful but cheap or homemade... I find my wooden sawhorses to be very useful. I had the car body sitting on them over last winter while I was doing the trunk floor, I made them the same height as my p/u tailgate, I can actually make a pretty long worktable using two horses and the truck, I throw an old door on them to make a quick worktable wherever I want it set up & a 100 other uses!

C

what a great idea. as I was looking at mine thinking there must be a easy way to do that without damaging the chrome. I took your advice and removed mine today without damaging anything. do you realize how much info is available on this site from willing a-body friends who are so eager to share. So far all I can do is ask but one day maybe I'll know enough to help.

thanks

thanks

Glad to hear it Tadams. I'm always happy to hear that someone is further along on their project. I know that there are probably a hundred different ways to remove stuff, and I just thought I would share one of mine to help others along if I can. Keep 'em fast and shiny boys and girls!!! Geof

bump

Thanks Geof

Thanks Geof

Look at the date of this thread Steve, this was one of my first threads ever here!!!! 😃

chryslerfat

Well-Known Member

Look at the date of this thread Steve, this was one of my first threads ever here!!!! 😃

And it still has purpose. Great job!

packerman16

Well-Known Member

- Joined

- May 3, 2008

- Messages

- 140

- Reaction score

- 2

beats my old bottle opener,great tip reel high teck.

beats my old bottle opener,great tip reel high teck.

I know, I know!!! What with that special angulated end, and that tab like thingy on there!!! And, I've got hundreds of them "in stock", so when one goes bad, just throw it on the fire and grab another!!!😄

KitCarlson

Well-Known Member

I have always used my fingers, no tool. Nice to know the wood works.

-