grimreaper

Cross Member

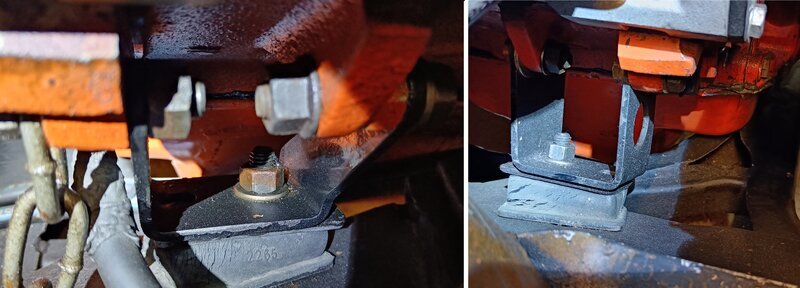

The 273/318 mounts can be modified to work for 340s by welding on a triangle ear and drilling a hole.

The 273/318 mounts can be modified to work for 340s by welding on a triangle ear and drilling a hole.

Wow....just a neighbor over the mountain! My sister-in-law lives in Johnson City and I go thru there fairly often. I've also got a friend over in Erwin.

You need to get that dip stick tube seated all the way down Jim!Pre-welding... piece was cut from the back side where there were 2 holes and only 1 tab on the 360/340

View attachment 1716057959

You need to get that dip stick tube seated all the way down Jim!

You need to get that dip stick tube seated all the way down Jim!

Almost correct on the motor mounts. Only the driver side needs changing, the passenger side should be the same.You might want to do some homework on the engine mounts if you are doing a 318 now and a 340 later. I believe they are different from a 273/318 and 340/360, so the 340 would need another set.

Thanks for the info! I'm genuinely surprised how difficult it is to find information about the mounts. I can't find any official info about the thickness of 2265, my local dealer tells me it's 36mm so that would be hair under 1.5". Rockauto tells me that 2469 would be 1.5" and 2710 would be 1.75" thick, so that makes me second guess the info from my local dealer. I need the replace the mounts with something ASAP just to get the car back on road, so maybe I just order pair of 2265 and try to look into the mounts and brackets with time. I would like to get either solid steel or poly mounts, but the options seem to be very limited. Looks like Moroso steel mounts are only 1" thick so they are probably way too low anyway. Maybe best long term solution would be if I try to source the 340 / 360 brackets and get poly mounts from Dodge polyurethane engine mountWith the 273 style Brackets 2710 (Napa 606-1653)biscuits from a diesel '90 W250 are close to the correct thickness and have locking tabs. The hole in the mount for the alignment pin has to be moved a bit.....

2469 aren't thick enough and let the engine sit too low.

With the Shumacher conversion mount the 2469 may be thick enough.

I call them block insulators and they are the same on all LA blocks, I believe 72' and down, then they used the roll mounts (different "K" member W/loops). It's the mount to block tabs that are different on the applications 273-318 or 340-360. I would not use a solid mount on a street motor. I had issues with breaking mounts (drivers side) in my 72' Van with a 340. I installed a chain at the mount to engine and the corrected the problem. I believe a solid mount would be hard on the motor, the frame and my body. On my van, I was able to tweak the tabs (318) to accommodate the 340, but they are longer on the van than the cars, so it was easy to adjust.Thanks for the info! I'm genuinely surprised how difficult it is to find information about the mounts. I can't find any official info about the thickness of 2265, my local dealer tells me it's 36mm so that would be hair under 1.5". Rockauto tells me that 2469 would be 1.5" and 2710 would be 1.75" thick, so that makes me second guess the info from my local dealer. I need the replace the mounts with something ASAP just to get the car back on road, so maybe I just order pair of 2265 and try to look into the mounts and brackets with time. I would like to get either solid steel or poly mounts, but the options seem to be very limited. Looks like Moroso steel mounts are only 1" thick so they are probably way too low anyway. Maybe best long term solution would be if I try to source the 340 / 360 brackets and get poly mounts from Dodge polyurethane engine mount

Edit: After some googling I can't find anything which would indicate that there is height difference between 273 and 360 mounts, only difference I could find was with the mounting tabs.

The car is currently built solely for drag racing, and it get's very few miles on the road, so I'm thinking the solid mounts could be viable option. I'm more concerned about the engine twisting when accelerating, but let's see if that issue gets better with the new rubbers.I call them block insulators and they are the same on all LA blocks, I believe 72' and down, then they used the roll mounts (different "K" member W/loops). It's the mount to block tabs that are different on the applications 273-318 or 340-360. I would not use a solid mount on a street motor. I had issues with breaking mounts (drivers side) in my 72' Van with a 340. I installed a chain at the mount to engine and the corrected the problem. I believe a solid mount would be hard on the motor, the frame and my body. On my van, I was able to tweak the tabs (318) to accommodate the 340, but they are longer on the van than the cars, so it was easy to adjust.

'67-72 V8 mounts are the same, but '64-66 V8 mounts are thicker. Block mount brackets are also different between early and late.I call them block insulators and they are the same on all LA blocks, I believe 72' and down, then they used the roll mounts (different "K" member W/loops). It's the mount to block tabs that are different on the applications 273-318 or 340-360. I would not use a solid mount on a street motor. I had issues with breaking mounts (drivers side) in my 72' Van with a 340. I installed a chain at the mount to engine and the corrected the problem. I believe a solid mount would be hard on the motor, the frame and my body. On my van, I was able to tweak the tabs (318) to accommodate the 340, but they are longer on the van than the cars, so it was easy to adjust.

Did they have the locking tabs also encased in the rubber, or are the locking tabs separated?I just purchased the Pioneer engine mount 602710 for a diesel truck from rock auto, under $12.00 and all you have to do is drill another locating hole in the bracket. The mount looks good and has the locking tabs.

For racing only I would still use sone type of restraint on the lift of the driver side. Chain, steel strap or a factory had one already incorporated into the mount. I believe I seen them in vans. I broke a few before I learned, even new ones.The car is currently built solely for drag racing, and it get's very few miles on the road, so I'm thinking the solid mounts could be viable option. I'm more concerned about the engine twisting when accelerating, but let's see if that issue gets better with the new rubbers.