You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

eBay dual snorkel hood scoop install.....

- Thread starter 318willrun

- Start date

-

Pretty cool man! Do you have plans to seal the carburetor to the hood somehow?

well, that would be a plan but we'll see if it ever happens... LOLPretty cool man! Do you have plans to seal the carburetor to the hood somehow?

well, that would be a plan but we'll see if it ever happens... LOL

Take a look at the carburetor pan by Moroso. It should be easy for someone with your skills to duplicate.

dartfreak75

Restore it, Dont part it!

Very cool. Thanks for sharing. I always enjoy your videos!

Love how you have the "git r dun" work ethic. Thanks for the videos.

famous bob

mopar misfit

COOL . U may find that the incoming air will pressurize the engine compartment , on the hi way , and fight ur radiators air flow , if it`s not sealed to the hood..

Depends on how much heat the engine is making----------

Great video! Thanks for doing that!!

moparmat2000

Well-Known Member

I bought one of these. So heres the real skinny on the fatty. I had to do a fair amount of grind and fit to get it to line up with the hood contour. 69 barracuda. Same as 73-76 dart. They dont fit as tightly as what's in my pix without a fair amount is machine sanding and fitting multiple times. Took me a half a day to chase down the gaps all around so it fit right.

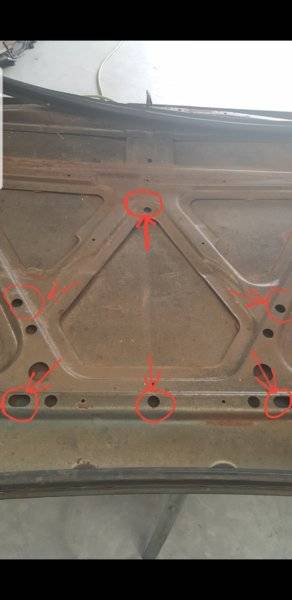

I would NOT recommend what the guy on the video says about line it up where you think it looks good since the structure underneath has access holes for the mounting nuts. These holes are in 6 key locations in the hood under structure. The remaining 2 mounting holes are not hidden in the structure, and are clearly visible. Note my picture below. The 3 across are at the back of the scoop.

Anyhow, to get it to line up with these key points, what I did was find the hood center front to back, then with a straightedge, draw a line down the center of the hood front to back, and draw a center line on the front center of the scoop. If your paint is in good condition, just stick down some 2" wide masking tape everywhere, then draw on that. Just be aware, the hoods on A bodies are not perfectly square, and do taper in at the front. Your side to side dimension at the back to find the centerline will be different than the side to side dimension at the front to find the centerline.

NOTE: This job may actually be easier to do if the hood is off the car and sitting on saw horses. Also i recommend using a unibit as it will give you a cleaner hole and not possibly warp the hood sheetmetal like a regular drill bit can. I get mine from Harbor Freight dirt cheap. Actually one of the few tools I grab up and stock up on when they put em on sale.

The threaded mounting holes on the aftermarket scoop are SAE thread, and almost dead ringer in all the stock locations. If you line up and drill your front center hole where it lines up with the access hole in the hood inner structure as well as centered on your hood center line, then measure center of hole to center of hole from front to back on the scoop itself, then, transfer that measurement from the center of the front hole on the hood back along your drawn centerline to find the rear hole. Double check your measurements, and then drill it. They both should line up with the hardware access holes in the hood under structure.

After that, I made an accurate template patterned off the front and rear mount points on the scoop itself to get the other hole locations on the scoop, transferred that to the hood, and drilled them with a uni bit. When making this template I marked it which side faced up towards the scoop, and which side faced down against the hood. This is pretty important, since the scoop being aftermarket, I was concerned that the mounting points on it could be off a little on each side and not an exact mirror image.

NOTE: Orienting your template this way will assure you that the holes should line up centered in the drill hole or extremely close to center when you drill them. I drilled them out to 7/16" with my uni bit, however I still had to clearance some of the holes a just little with a rotary file to get the studs to fit through.

NOTE: I recommend you pitch the bolts it comes with in your hardware box, and go buy threaded rod from lowes or home depot to make studs. This will make the install a whole lot easier. I went to lowes and bought threaded rod. Cut it into studs, and also bought Sems styled nuts there too. A few of the access holes in the structure were slightly off as this is not a true accurate repop, and those holes I had to use a rotary file to file them open slightly to get it to where I could get a socket in there with a nut.

The cutouts in the front are a bit crude, but with a $100 scoop I expected that. I plan on opening up, and filing them out smooth to look more like an OEM scoop, and use a bit of body filler to make a silk purse out of it. It is notched in the front and back for a duster, though the rear is severely notched. This will require a bit of fiberglassing, i will also have to cut 4 small slits in it where it mounts to the hood for water drainage like the stocker had. Even with these minor annoyances however the mount holes line up really good with the stock access holes in the structure.

Hope this helps

Matt

I would NOT recommend what the guy on the video says about line it up where you think it looks good since the structure underneath has access holes for the mounting nuts. These holes are in 6 key locations in the hood under structure. The remaining 2 mounting holes are not hidden in the structure, and are clearly visible. Note my picture below. The 3 across are at the back of the scoop.

Anyhow, to get it to line up with these key points, what I did was find the hood center front to back, then with a straightedge, draw a line down the center of the hood front to back, and draw a center line on the front center of the scoop. If your paint is in good condition, just stick down some 2" wide masking tape everywhere, then draw on that. Just be aware, the hoods on A bodies are not perfectly square, and do taper in at the front. Your side to side dimension at the back to find the centerline will be different than the side to side dimension at the front to find the centerline.

NOTE: This job may actually be easier to do if the hood is off the car and sitting on saw horses. Also i recommend using a unibit as it will give you a cleaner hole and not possibly warp the hood sheetmetal like a regular drill bit can. I get mine from Harbor Freight dirt cheap. Actually one of the few tools I grab up and stock up on when they put em on sale.

The threaded mounting holes on the aftermarket scoop are SAE thread, and almost dead ringer in all the stock locations. If you line up and drill your front center hole where it lines up with the access hole in the hood inner structure as well as centered on your hood center line, then measure center of hole to center of hole from front to back on the scoop itself, then, transfer that measurement from the center of the front hole on the hood back along your drawn centerline to find the rear hole. Double check your measurements, and then drill it. They both should line up with the hardware access holes in the hood under structure.

After that, I made an accurate template patterned off the front and rear mount points on the scoop itself to get the other hole locations on the scoop, transferred that to the hood, and drilled them with a uni bit. When making this template I marked it which side faced up towards the scoop, and which side faced down against the hood. This is pretty important, since the scoop being aftermarket, I was concerned that the mounting points on it could be off a little on each side and not an exact mirror image.

NOTE: Orienting your template this way will assure you that the holes should line up centered in the drill hole or extremely close to center when you drill them. I drilled them out to 7/16" with my uni bit, however I still had to clearance some of the holes a just little with a rotary file to get the studs to fit through.

NOTE: I recommend you pitch the bolts it comes with in your hardware box, and go buy threaded rod from lowes or home depot to make studs. This will make the install a whole lot easier. I went to lowes and bought threaded rod. Cut it into studs, and also bought Sems styled nuts there too. A few of the access holes in the structure were slightly off as this is not a true accurate repop, and those holes I had to use a rotary file to file them open slightly to get it to where I could get a socket in there with a nut.

The cutouts in the front are a bit crude, but with a $100 scoop I expected that. I plan on opening up, and filing them out smooth to look more like an OEM scoop, and use a bit of body filler to make a silk purse out of it. It is notched in the front and back for a duster, though the rear is severely notched. This will require a bit of fiberglassing, i will also have to cut 4 small slits in it where it mounts to the hood for water drainage like the stocker had. Even with these minor annoyances however the mount holes line up really good with the stock access holes in the structure.

Hope this helps

Matt

Last edited:

-