pishta

I know I'm right....

Bought a Bosch EFI pump for an EFI conversion out of the scrap yard. Snagged it out of an 86 MB 420SEL or so. External pump, inline..perfect or an EFI conversion. Well, should have bought the 4 buck insurance because the thing was seized beyond hope. So what to do? Dissect it!

Wondered how these pump 50 GPH at 85 PSI? Well, the entire thing is a motor, well, about 90% of it is. I took a tube cutter and parted the AL case and pulled it apart. Suprisingly, the entire inlet side came off as a shell including the armature (its Circlipped to the stationary shaft) It surrounded another metal case that held the magnets and brushes. The pump mechanism is similar to an oil pump as it has a round disk with 5 metal "barrels" in D shaped cutouts. This rides in a circular stationary race that is slightly off center of the rotating disk. The high speed of the rotating disk throws out the metal barrels to the side of the race and picks up fuel from an inlet slot about 1/4 way around the race. The barrels seal off the fuel charge and continue around while being compressed by the offset race, like an oil pump or more like a water pump on an outboard motor. The gerotor rotates to its highest compression spot (smallest volume) and then passes a small port that releases it into the O ringed armature part of the case. So the armature is spinning in a "can" full of pressurized gasoline, brushes and all! I thought that would be a time bomb waiting to go off, but I guess the absence of oxygen in there prevents ignition? That was very suprising to me. So the gas then just flow up to the top and out the pressure port. There is a small spring relief valve on the pump side to vent fuel back into the inlet side and I suppose you could manipulate the output pressure with that small spring rate. So the brushes and armature degrade and the trash is washed away by the fuel right into the fuel filter. Why they cost $200 bucks and more is beyond me.

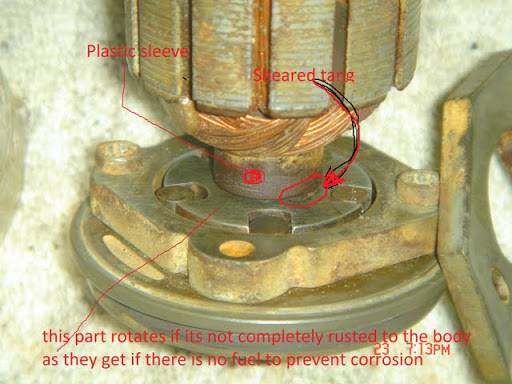

So if you have a dry one that is seized, first thing I would do is invert and fill the thing with WD40 into the inlet side. Thats the side closest to the geroter. The metal rotating disk gets corroded/rusted with the lack of fuel and just glues itself to the close tolerances of the pump mechanism. Mine was so corroded inside (I bought the best looking on the outside of 5 at the yard, looked like it was new!) that I almost missed 2 of the barrels when I took it apart because I couldnt see them. I would then apply voltage to it a few times and see if it starts to turn. Keep doing this over a few days of possible because once you take the armature out, the brushes pop out and make putting the armature back in almost impossible if you dont cut it in the right spot. The armature connects to the gerotor ( I think thats what its called) with 2 fingers, just like a torque convertor into the front pump, and the fingers are made of a hard plastic as best as I can tell, which sheared off when I manually turned the armature when I got the thing seperated (Dont do this or youll surely ruin the pump) instead, remove the circlip on the top of the armature and the entire armature slides off the shaft, uncoupling from the geroter. You can now Get your T-20 torx driver and remove the geroter assembly and clean it. ---You dont have to remove the pump body from the case-- you probably will never get it back in as it is an O-ringed press fit. These things are not made to be taken apart, but if you are adventurous and can get the armature back between the brushes AND reseal the thing (TIG weld the radial cut you made?) as this is under 45+ PSI of pressure, go for it. There are $1000+ versions of these inline pumps, they better be serviceable for that kind of money!

If you are going to repair these, make your cut exactly 1/2 inch below the top of the aluminum case, youll be able to retract your brushes around the armature and still have a lip to put the case back onto. From here, you just take the top off, remove the circlip on top of the shaft, and slide the armature off. Use a long T-20 to get the pump parts unscrewed in the bottom of the lower shell, and remove the corroded pump cover and rotor. You just might be able to save it!

Wondered how these pump 50 GPH at 85 PSI? Well, the entire thing is a motor, well, about 90% of it is. I took a tube cutter and parted the AL case and pulled it apart. Suprisingly, the entire inlet side came off as a shell including the armature (its Circlipped to the stationary shaft) It surrounded another metal case that held the magnets and brushes. The pump mechanism is similar to an oil pump as it has a round disk with 5 metal "barrels" in D shaped cutouts. This rides in a circular stationary race that is slightly off center of the rotating disk. The high speed of the rotating disk throws out the metal barrels to the side of the race and picks up fuel from an inlet slot about 1/4 way around the race. The barrels seal off the fuel charge and continue around while being compressed by the offset race, like an oil pump or more like a water pump on an outboard motor. The gerotor rotates to its highest compression spot (smallest volume) and then passes a small port that releases it into the O ringed armature part of the case. So the armature is spinning in a "can" full of pressurized gasoline, brushes and all! I thought that would be a time bomb waiting to go off, but I guess the absence of oxygen in there prevents ignition? That was very suprising to me. So the gas then just flow up to the top and out the pressure port. There is a small spring relief valve on the pump side to vent fuel back into the inlet side and I suppose you could manipulate the output pressure with that small spring rate. So the brushes and armature degrade and the trash is washed away by the fuel right into the fuel filter. Why they cost $200 bucks and more is beyond me.

So if you have a dry one that is seized, first thing I would do is invert and fill the thing with WD40 into the inlet side. Thats the side closest to the geroter. The metal rotating disk gets corroded/rusted with the lack of fuel and just glues itself to the close tolerances of the pump mechanism. Mine was so corroded inside (I bought the best looking on the outside of 5 at the yard, looked like it was new!) that I almost missed 2 of the barrels when I took it apart because I couldnt see them. I would then apply voltage to it a few times and see if it starts to turn. Keep doing this over a few days of possible because once you take the armature out, the brushes pop out and make putting the armature back in almost impossible if you dont cut it in the right spot. The armature connects to the gerotor ( I think thats what its called) with 2 fingers, just like a torque convertor into the front pump, and the fingers are made of a hard plastic as best as I can tell, which sheared off when I manually turned the armature when I got the thing seperated (Dont do this or youll surely ruin the pump) instead, remove the circlip on the top of the armature and the entire armature slides off the shaft, uncoupling from the geroter. You can now Get your T-20 torx driver and remove the geroter assembly and clean it. ---You dont have to remove the pump body from the case-- you probably will never get it back in as it is an O-ringed press fit. These things are not made to be taken apart, but if you are adventurous and can get the armature back between the brushes AND reseal the thing (TIG weld the radial cut you made?) as this is under 45+ PSI of pressure, go for it. There are $1000+ versions of these inline pumps, they better be serviceable for that kind of money!

If you are going to repair these, make your cut exactly 1/2 inch below the top of the aluminum case, youll be able to retract your brushes around the armature and still have a lip to put the case back onto. From here, you just take the top off, remove the circlip on top of the shaft, and slide the armature off. Use a long T-20 to get the pump parts unscrewed in the bottom of the lower shell, and remove the corroded pump cover and rotor. You just might be able to save it!