I recently replaced the carb with a more correct carter 2 barrel (the one that was on there was not original, the one I bought looks right but didn't come with a tag) and am having some issues where the engine will lose power if I quickly press the gas. The faster I press the gas, the more power it loses for a few seconds, up to the point of stalling the engine. A few seconds later, the engine revs up to what you would normally expect. It does not do this when not in gear, and the slower you are going, the bigger the problem is.

My first guess was air/fuel too lean, the extra vacuum leans out the mixture and the engine stalls I don't have a air fuel mixture meter and want to avoid buying one. I saw on you tube that you can adjust that by looking at the vacuum (I do have a vacuum gauge) but the screws don't seem to have any affect on the vacuum, or how the engine runs at idle for that matter. That seems not right to me, but I thought I read somewhere that on some models of BBD carbs, those adjustments don't do anything?

I have also confirmed that the carb does squirt fuel into the barrels when the gas is pressed, so maybe its just not squirting enough? Too much? which brings me to...

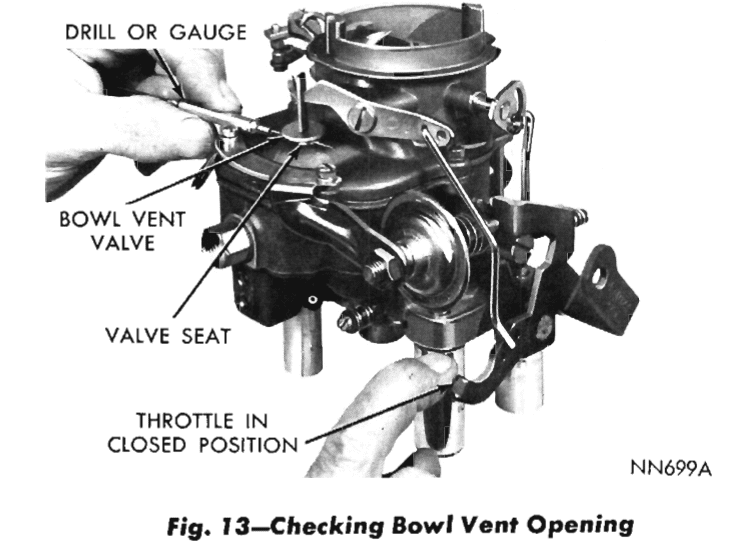

In the service manual, in the accelerator pump and bowl vent adjustment section there are references to a bowl vent clip. My carb did not come with one as far as I know, so I think this could be the issue, but I'm not really sure what its supposed to look like. Right now the bowl vent is just sorta sitting on top of the bowl, no clip, and I'm not sure this is what I need.

Carter BBD Bowl Vent Clip

I don't see anything in the figure from the service manual that looks like that.

Any info is appreciated.

68 barracuda, 318

My first guess was air/fuel too lean, the extra vacuum leans out the mixture and the engine stalls I don't have a air fuel mixture meter and want to avoid buying one. I saw on you tube that you can adjust that by looking at the vacuum (I do have a vacuum gauge) but the screws don't seem to have any affect on the vacuum, or how the engine runs at idle for that matter. That seems not right to me, but I thought I read somewhere that on some models of BBD carbs, those adjustments don't do anything?

I have also confirmed that the carb does squirt fuel into the barrels when the gas is pressed, so maybe its just not squirting enough? Too much? which brings me to...

In the service manual, in the accelerator pump and bowl vent adjustment section there are references to a bowl vent clip. My carb did not come with one as far as I know, so I think this could be the issue, but I'm not really sure what its supposed to look like. Right now the bowl vent is just sorta sitting on top of the bowl, no clip, and I'm not sure this is what I need.

Carter BBD Bowl Vent Clip

I don't see anything in the figure from the service manual that looks like that.

Any info is appreciated.

68 barracuda, 318