OK here are a couple more thing to chew on.......like you don't have enough opinion already:-D

Hang on, its a long one!!!!!

FIRST, I agree with mopar340dave in that the push rod was to long! so long that the hyd "port" of the lifter wasn't working from day 1!

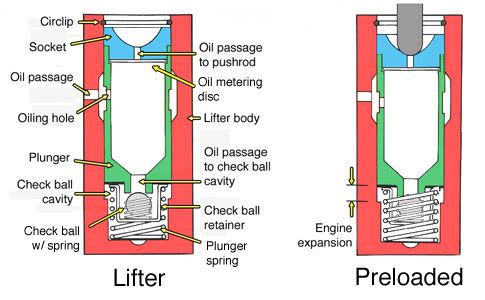

The spring in side was what was taking up the play and eventual collapse from constant moment......like the video shows when there was no oil.

That's why it wont pump up now. oil is leaking around the plunger, do to excessive were...........OK getting to deep into it again,sorry.

If the push rod would have been any longer, the valve would have been held open and the eng would NOT have started(

THIS IS SPECULATION, YOU HAVEN'T PROVED IT ONE WAY OR THE

OTHER.....YET :clock

SECOND, The spring is a bit high(pressure wise).....but if it was installed at 1.75,(Causing the push rod to push even deeper into the lifter) I thing its acceptable....as in,... not the cause of you problem, or a part of your problem.

THIRD,.... FOR GET ABOUT EVERY THING EXCEPT THE CAUSE OF THE PROBLEM! Which i thing, the hole lot of us, believe is the PUSH ROD LENGTH.

THIS IS MY WAY OF FINDING OUT PUSH ROD LENGTH!

First, (if you are NOT sending you lifters/cam back to lunati)

You need to fill up one of you lifters with GLUE! Yes glue, you could even us super glue. What every you us it must have the plunger up agenced the clip. Now you have a solid lifer of proper height( You could also set the lifter down .040" but that gets more complicated)

Now, You need to by a adj push rod from who who ever you decide to by the push rods from.....I don't matter, pick one and get and adj push rod.

Now with this push rod you can set your proper push rod length.

once you have adj the push rod to (0) end play, lock the nut.

Now if the height of all the valve stems are the same, sent the adj push rod back and tell them. You want .040" longer then the push rod you sent back.

By using a straight edge across all the valve. And using a thickness gauge, you can find out how many thousands difference there is between. them.

Example: Say you lay a straight edge across the valves on one head and the shortest valve is .020" shorter(which it shouldn't be.) so you adj the push rod to the tallest valve/ rocker arm.

Now you need to average it.

The shortest valve is > .020"/ by 2=.010". Now .010+.040=.050" so now you send the push rod back and tell them that you need a set of push rods .050" longer then the push rod you sent back.

A Side Note here, According to "Mother Mopar", there lifters have a

.180" travel and .030 at either end, is Not usable, so that leave you with 120 to play with in the middle.

so i would say from .040 to .080" would be a safe place to play with any Hyd lifter(only ASSuMe...ing here!) so the .050 would be in the safe zone with some margin on either end.

YOU Have to PROVE the push rod is yourrrrrrr problem, before you can go any further.......

JMHO.

Final note, if you glue a lifter, Make Sure you paint it a bright color so it don't get installed (accidentally) and bend/ brake valve/piston!:read2: