furyus2

Well-Known Member

Has anyone bought one of those Summit front end alignment setups? Did it work well? Do i need those plates to turn the tires? I'm tired of paying $100 for someone to do it wrong.

You need a different alignment shop. The big box tire stores with 18 year old's running the new machines can't help. I am leary of the new specs the machines have. Most new guys wouldn't know what to change if there was a pulling problem.Has anyone bought one of those Summit front end alignment setups? Did it work well? Do i need those plates to turn the tires? I'm tired of paying $100 for someone to do it wrong.

Any kit someone would suggest. I have 3 classics, and I've gone to a shop I've always used. They knocked a chunk out of my custom wood wheel. Then I took the Dart to them. Steered worse than when I took it in. Went to another shop with am old guy. Still steered like crap. Wandered all over. I set the toe with a tape measure, and gave it all the caster i could. Way more stable, but still needs work. Had the first shop do my 64 Sport Fury, and I noticed the inside of the tires are wearing. And yes, all these front suspensions were rebuilt. With all of this, I would rather do it myself. I just need good advice on a kit. And i really liked the idea of plastic under the tires. That alone saves $300.which one?

You didn't mention what was wrong. Tire wear? Pulling to one side or another? Too much neutral steer? Direction hunting? hard to turn at low speeds with manual steering?Has anyone bought one of those Summit front end alignment setups? Did it work well? Do i need those plates to turn the tires? I'm tired of paying $100 for someone to do it wrong.

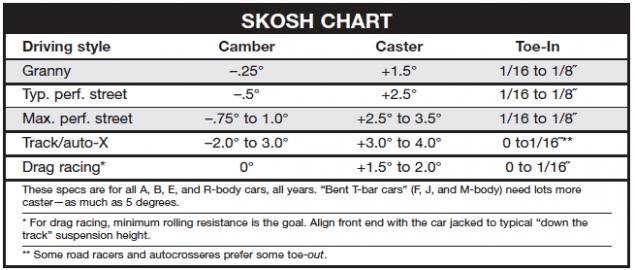

I will add that caster is key. With stock components I would shoot for as much as you can. That's why aftermarket UCAs are nice, you can get more caster out of them.

The biggest issue to overcome with home alignment is, you must have an accurate way to measure caster.

Actually Rob that is not true. If you can measure CAMBER then you can measure/ calculate caster. My old Ammco caster/ camber gauge measures camber, and caster is computed from that by what amounts to a rotary slide rule on the instrument.

You measure camber with the wheels turned one way, 20* in, then measure camber again with wheels turned 20* out. You figure the DIFFERENCE in that reading and multiply X 1.5 That answer is your caster

But you still have to have the tool, right? That was my point. We had an OLD Bear mirror machine at the KMart Auto Center where I met Kitty years ago. It had the very caster/camber gauge you describe. It was archaic, but I liked it because it worked.

Has anyone bought one of those Summit front end alignment setups? Did it work well? Do i need those plates to turn the tires? I'm tired of paying $100 for someone to do it wrong.

Ok. I will watch some youtube videos to get an idea of what to do. I do have a digital level. My questions are how do you know the gauge is on level to start? Do you level the car front to back, and side to side to start? How do you measure 20 degrees to get the caster? Thanks.

Ok. I will watch some youtube videos to get an idea of what to do. I do have a digital level. My questions are how do you know the gauge is on level to start? Do you level the car front to back, and side to side to start? How do you measure 20 degrees to get the caster? Thanks.