Cuda Al

Well-Known Member

I have a new/reproduction sender in my car and it doesn't read correctly, it hits empty at half tank. I had been planning on adjusting the float to move empty to empty but I thought about looking into what could be done with the original.

I had three to work with and none worked.

The first one (cleanest) was looked at and the first thing I noticed was the phenolic board was slipping out so I removed it. I tested it with a meter and it was within the correct range.

All three units were put in vinegar over night and cleaned, I then looked to see what it would take to take them apart and find out why they didn't work.

The first one I noticed the pointer was off axis and was loose on the shaft so it was put aside (stripped of all parts).

The second unit was cleaned and examined and everything seamed fine, the insulator was still intact.

The rest of the parts were cleaned up and sorted through.

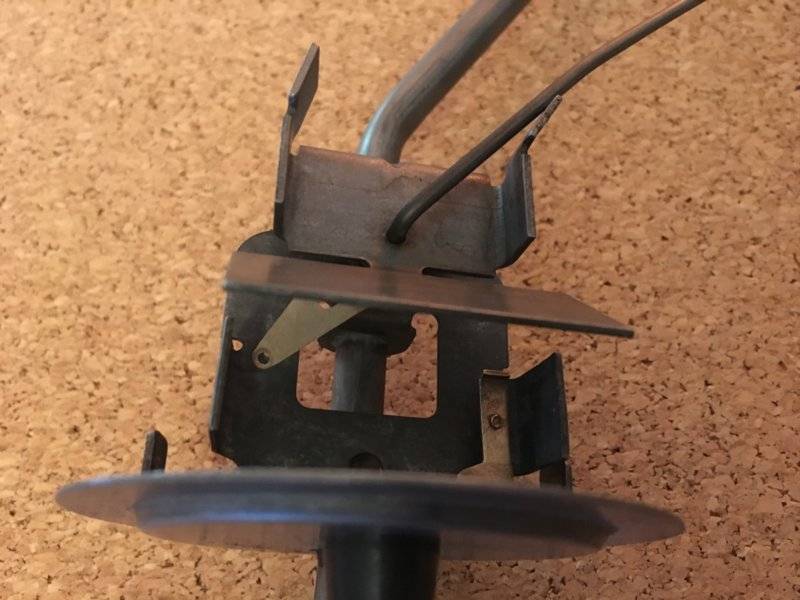

The board fits into the main frame on on end and on the contact bar on the other, it appears that the pressure of the pointer holds in in place.

The board was then installed.

I then took my meter and put it through the motions with mixed results, sometimes nothing, sometimes spotty. In checking I came to the conclusion that the board was originally riveted to the copper bar. The other bars and board were looked at and I felt I could solder them together.

I had three to work with and none worked.

The first one (cleanest) was looked at and the first thing I noticed was the phenolic board was slipping out so I removed it. I tested it with a meter and it was within the correct range.

All three units were put in vinegar over night and cleaned, I then looked to see what it would take to take them apart and find out why they didn't work.

The first one I noticed the pointer was off axis and was loose on the shaft so it was put aside (stripped of all parts).

The second unit was cleaned and examined and everything seamed fine, the insulator was still intact.

The rest of the parts were cleaned up and sorted through.

The board fits into the main frame on on end and on the contact bar on the other, it appears that the pressure of the pointer holds in in place.

The board was then installed.

I then took my meter and put it through the motions with mixed results, sometimes nothing, sometimes spotty. In checking I came to the conclusion that the board was originally riveted to the copper bar. The other bars and board were looked at and I felt I could solder them together.