I swapped a 5.9 into my dart about 2.5 years ago. I got my grandpa's hand me down truck and absolutely loved it. I drove it in high school and even after. I got rear ended and totaled the truck about 5 years ago. I pulled the engine and saved it for my dart.

I planned on headers, aluminum intake, and a 727 with an otherwise stock 5.9 magnum. It ran great but had a hard start issue and the secondaries didnt cooperate on the used and unknown edelbrock carb. Bought a new demon 625 and had it running great... until the headgasket let go. The distributor didn't get tightened down and I assume that detonation or simply old age caused it.

I pulled the engine bored it .030 over, installed KB107 pistons, EQ 2.02 heads, 218/222 @.050 .539/.549 lift cam, double roller chain, 750 carb etc. That was a sweet motor and went 12.88 @104 with a 3.55 gear at 3300 pounds. And relatively untuned and running rich per the AFR gauge.

I was hooked and wanted more power. It all snowballed as these things tend to do. And I pulled the engine back out. I found the the magnum tensioner and timing chain weren't playing nicely together and the bearings were all pretty scuffed up from the tensioner guide material. So I honed the cylinders, new rings, main, and rod bearings were installed. And then I swapped on a set of edelbrock heads that have been "cleaned up" by Hughes. And installed a 238/242 @.050 571/576 lift cam.

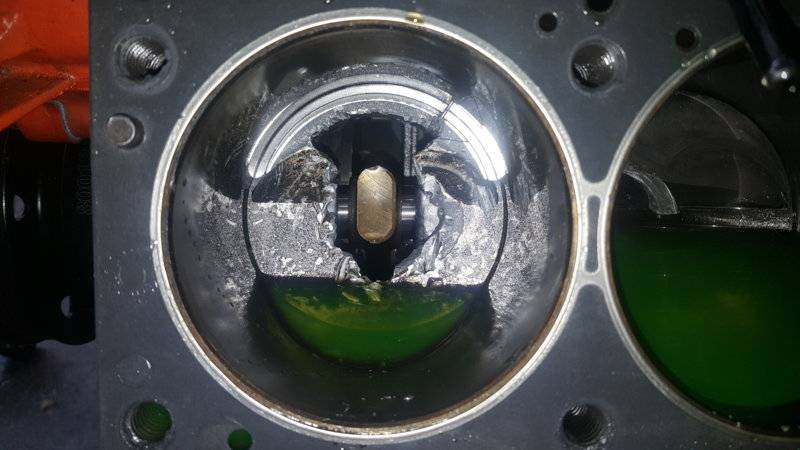

It all went together great. I thought. I've overhauled engines and done plenty of repair work but this is the only "performance" engine I've built. And my lack of experience and knowledge bit me. Within a few miles of driving, the intake valve on #1 broke. It shattered the piston and found it's way into the pan and even put a hole in it. Pieces of piston surprisingly got into every cylinder. The cylinder wall is gouged, pan busted, windage tray damaged, heads are beat up, it's bad. Upon teardown it appears that the cam is timed correctly but all of the pistons show the intake valves was hitting. I timed it dot to dot. The exhaust has more lift and duration but the intake hit.

It's a long post, I know. But should I have to degree this cam? It's pretty sickening to know that I bought a cam degree kit to use on this engine but have no idea how to use it. How common is something like this? Are the KB107's not deep enough?

I planned on headers, aluminum intake, and a 727 with an otherwise stock 5.9 magnum. It ran great but had a hard start issue and the secondaries didnt cooperate on the used and unknown edelbrock carb. Bought a new demon 625 and had it running great... until the headgasket let go. The distributor didn't get tightened down and I assume that detonation or simply old age caused it.

I pulled the engine bored it .030 over, installed KB107 pistons, EQ 2.02 heads, 218/222 @.050 .539/.549 lift cam, double roller chain, 750 carb etc. That was a sweet motor and went 12.88 @104 with a 3.55 gear at 3300 pounds. And relatively untuned and running rich per the AFR gauge.

I was hooked and wanted more power. It all snowballed as these things tend to do. And I pulled the engine back out. I found the the magnum tensioner and timing chain weren't playing nicely together and the bearings were all pretty scuffed up from the tensioner guide material. So I honed the cylinders, new rings, main, and rod bearings were installed. And then I swapped on a set of edelbrock heads that have been "cleaned up" by Hughes. And installed a 238/242 @.050 571/576 lift cam.

It all went together great. I thought. I've overhauled engines and done plenty of repair work but this is the only "performance" engine I've built. And my lack of experience and knowledge bit me. Within a few miles of driving, the intake valve on #1 broke. It shattered the piston and found it's way into the pan and even put a hole in it. Pieces of piston surprisingly got into every cylinder. The cylinder wall is gouged, pan busted, windage tray damaged, heads are beat up, it's bad. Upon teardown it appears that the cam is timed correctly but all of the pistons show the intake valves was hitting. I timed it dot to dot. The exhaust has more lift and duration but the intake hit.

It's a long post, I know. But should I have to degree this cam? It's pretty sickening to know that I bought a cam degree kit to use on this engine but have no idea how to use it. How common is something like this? Are the KB107's not deep enough?