mullinax95

Well-Known Member

My front bezels on my 67 cuda wasn't the best of shape because they had scratches, dents, and warped. I started to look around on my options of getting them looking better or replaced and found that it is very expensive to have them restored to new condition. I searched the threads on FABO and found places that will take your trim and give you a quote. Also posted a thread on the topic and asked fellow members what they did. This goes right into bunch of $$$$ that I just don't have. So I have tried to take task in hand myself since this is my hobby anyways.

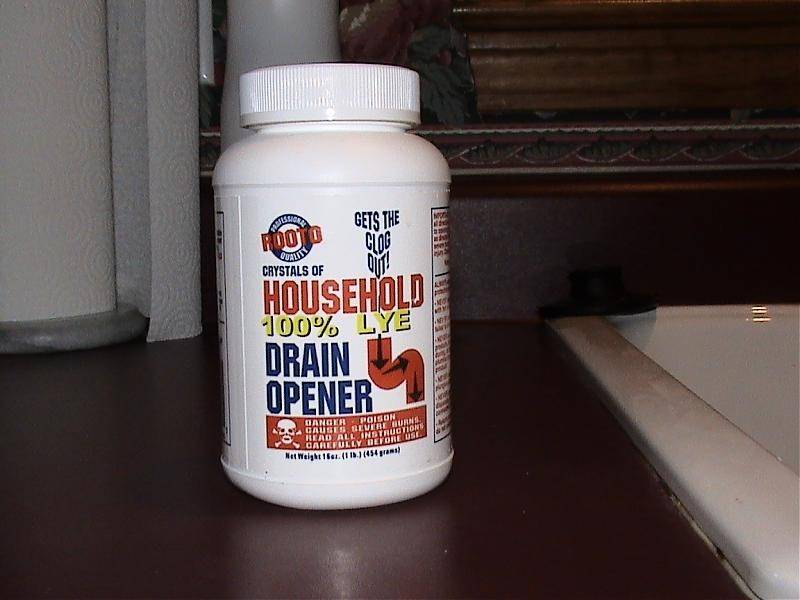

I have took everything off the front of the car that is associated to front bezel trim. I started with the left front bezel since it was worst of shape. I completely took it apart and started to sand the anodizing off to get down to bare aluminum. I found that getting it off was a chore. I talked to some guys at the local car show and got a really good tip. Some of you might not know this but I would like to post this so those that don't will know just in case. You can get some Lye, mix it with water and dip it. It will dissolve the anodizing right off! It made the job much simpler. I found it at the local hardware store. After I removed the anodizing I sanded the scratched out, fixed the dents and warped pieces.

I have took everything off the front of the car that is associated to front bezel trim. I started with the left front bezel since it was worst of shape. I completely took it apart and started to sand the anodizing off to get down to bare aluminum. I found that getting it off was a chore. I talked to some guys at the local car show and got a really good tip. Some of you might not know this but I would like to post this so those that don't will know just in case. You can get some Lye, mix it with water and dip it. It will dissolve the anodizing right off! It made the job much simpler. I found it at the local hardware store. After I removed the anodizing I sanded the scratched out, fixed the dents and warped pieces.