Dead set against a bump in the hood are ya? I don't blame ya.Here’s a picture of the fenders mocked up. You can see how much higher the engine sits, it’s going have to go down.

View attachment 1715585796

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I can't help myself

- Thread starter retroron

- Start date

-

It’s not going to be built with a bubble in the hood, not while I own it!Dead set against a bump in the hood are ya? I don't blame ya.

We're going to try different motor mounts first and see what we get. Induction is an issue, changing the intake will rob horsepower, so I don't want to do that. Moving the engine back and down is being considered along with a dry sump. I don't know of any low profile pan other than the one that's on it now.

I think to get the engine down below the plane of the hood the engine has to be moved, I hope I'm wrong.

I think to get the engine down below the plane of the hood the engine has to be moved, I hope I'm wrong.

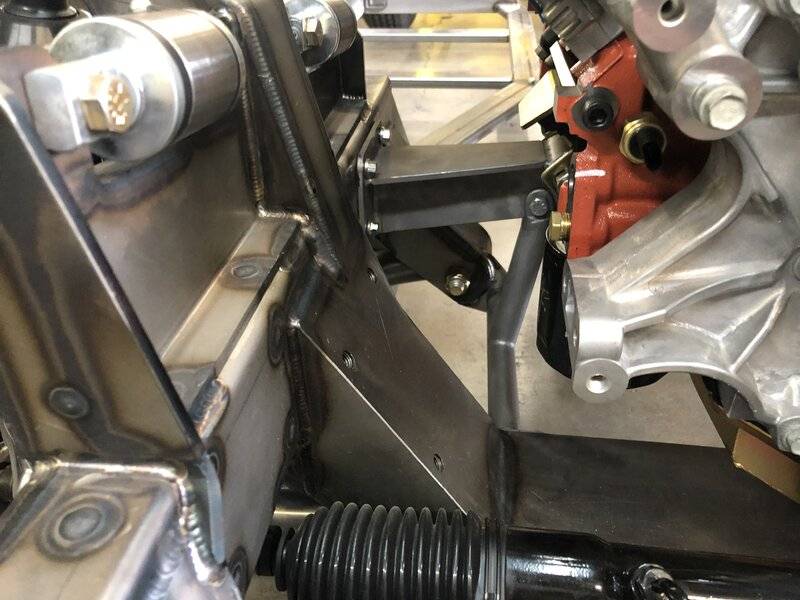

Some retrograde here, the engine is back 3 inches, down 2 inches and the body has been raised about 1 1/2 inches. Everything is real close to the final fit.

All the motor mounts, etc. will be fabbed in-house by SoCity. For my part I’ll bake the sourdough and write the checks.

All the motor mounts, etc. will be fabbed in-house by SoCity. For my part I’ll bake the sourdough and write the checks.

440jimr

Well-Known Member

I agree

Well, the way the setup is now I’ll have adequate ground clearance. Second, the dry sump cost is between $5-10K. And third the gen3 Hemi drives the oil pump off the front of the engine in a sun/planetary configuration, so I would have to tear down the front of the engine which I don’t want to do. Is that enough reasons for you?

And then there will be the additional fab required to mount the dry sump.

And then there will be the additional fab required to mount the dry sump.

Kursplat, now if you really want me to run a dry sump I’ll give you the name of the company that makes them for gen3 hemi’s. And I’ll graciously accept that dry sump from you cause that’s the kinda guy I am.

cripes, didn't realize there was that much to redo.Well, the way the setup is now I’ll have adequate ground clearance. Second, the dry sump cost is between $5-10K. And third the gen3 Hemi drives the oil pump off the front of the engine in a sun/planetary configuration, so I would have to tear down the front of the engine which I don’t want to do. Is that enough reasons for you?

And then there will be the additional fab required to mount the dry sump.

sorry, not that well off, but thanks for the offerKursplat, now if you really want me to run a dry sump I’ll give you the name of the company that makes them for gen3 hemi’s. And I’ll graciously accept that dry sump from you cause that’s the kinda guy I am.

I’m not that well heal’d either, but I am motivated to build this car, so if I have no other choice, I’ll bite the bullet and dry sump the engine. I just hope it doesn’t come to that.

Are you sure you don’t want to buy me that dry sump?

Are you sure you don’t want to buy me that dry sump?

you might test fit with the hood....on the A bodies, the hood actually bows up. With the engine installed, glancing across the fenders I think...uh-oh!, but upon adding a column of plumbers putty to different spots on the intake (for a gauge) and shut the hood....amazingly there is a good 1/2" of clearance. Naturally, the factory hood insulation is always first to go.

I would guess (I'm good at that) a custom, shorter oil pan / pick-up would be way cheaper and could be a massive gain. How much gain you ask?? measure how far the sump is now below the bellhousing?. No sense in anything any shorter than the bottom of the bell. With the rack / pinion out front and sans the factory steering linkage, shorten the pan / pick-up and add capacity out the sides and forward of the rear sump it appears you have. Kinda like a short, fat dragster pan.

you might be in better shape than you think. I hope you do not mind the chime in, hate to be that rail-bird helper....lots of ideas / no solutions.

I would guess (I'm good at that) a custom, shorter oil pan / pick-up would be way cheaper and could be a massive gain. How much gain you ask?? measure how far the sump is now below the bellhousing?. No sense in anything any shorter than the bottom of the bell. With the rack / pinion out front and sans the factory steering linkage, shorten the pan / pick-up and add capacity out the sides and forward of the rear sump it appears you have. Kinda like a short, fat dragster pan.

you might be in better shape than you think. I hope you do not mind the chime in, hate to be that rail-bird helper....lots of ideas / no solutions.

Last edited:

mygasser

Well-Known Member

you might test fit with the hood....on the A bodies, the hood actually bows up. With the engine installed, glancing across the fenders I think...uh-oh!, but upon adding a column of plumbers putty to different spots on the intake (for a gauge) and shut the hood....amazingly there is a good 1/2" of clearance. Naturally, the factory hood insulation is always first to go.

I would guess (I'm good at that) a custom, shorter oil pan / pick-up would be way cheaper and could be a massive gain. The question on how much gain is....how far is the sump now below the bellhousing?. No sense in anything any shorter than the bottom of the bell. With the rack / pinion out front and sans the factory steering linkage, shorten the pan / pick-up and add capacity out the sides and forward of the rear sump it appears you have. Kinda like a short, fat dragster pan.

you might be in better shape than you think. I hope you do not mind the chime in, hate to be that rail-bird helper....lots of ideas / no solutions.

agreed, most hoods bulge up in the centre. until you offer the fenders and hood up you wouldn't know for sure.

you say the body is lifted 1 1/2", you look to have more than that clearance under where the hood would be in those last pics. it's worth mocking the front end on there to check for sure. you may have enough room to lower the body back down some.

neil.

gts4fuji

Well-Known Member

Awesome build. At first I thought it was Brizzos shop in S. City.

Morning everyone, We are going to mock the fenders up again this week and see what we have. Denny, as you suggest, the oil pan is going to be the lower limiting feature. Right now the lowest part of the drive train is the bell housing, the oil pan (mid sump) is about 1/2 inch above the plane of the bell housing. Nothing is below the plane of the chassis. The engine had to go back for the pan to clear the cross member, there was no getting around it. The high point of the engine is the PCV box on the intake and we are working the problem. I want to keep the VVT which makes manifold changes questionable. But, as in all things, my thoughts can be re-shaped regarding manifolds (or anything for that matter). Stay tuned more to come this week.

Got the motor mounts fabbed up and fitted. Engine gets installed next week.i

3406pk

Well-Known Member

Those are some awesome looking welds.Got the motor mounts fabbed up and fitted. Engine gets installed next week.i

Red Stripe

Well-Known Member

Awesome build!

Any ideas on what wheels & brakes you are going with?

Any ideas on what wheels & brakes you are going with?

Wilwood brakes, 6 piston up front, four in the back. I’m thinking I may do “one-off” wheels. Brakes are next on the build schedule.

Finalized the engine location and loaded the engine on the finished mounts, might set the body tonight. more to come tomorrow.

when does the manifolds / headers go on?....will they be custom, or out of the box? sorry, I've already turned the page. Also,may I ask, is the engine mount a solid mount?...or doe's it have something to dampen engine vibration?

Gee Denny, you’re full of questions today. So in no particular order, the engine mounts have poly bushings. The headers out of necessity will be one-off. We’re still discussing header and exhaust diameters. I’m not sure when we’ll fab the headers, the big issue continues to be the manifold/hood/cowl interference. Feel free to offer suggestions. We are giving thought to modifying the stock manifold.

Last edited:

-

Similar threads

- Replies

- 41

- Views

- 3K

- Replies

- 33

- Views

- 3K

- Replies

- 21

- Views

- 3K

- Replies

- 21

- Views

- 3K

- Replies

- 41

- Views

- 564