67Dart273

Well-Known Member

With all the hoorah about ammeters, member Ironracer sent me an external shunt meter out of a 76 A body The face is marked +/- 40A (photos shamelessly stolen off the www)

Why? Because if you REALLY want an ammeter, this setup would solve the bulkhead connector and "full current" ammeter failures

Initial tests.............very unscientific, LOL. I simply took one of my good Fluke meters and wired it in series with the new meter, and then wired a second Fluke across the new meter to measure the voltage across it

"Quck" tests show that

100mv (millivolts) is across the meter and the system is drawing about .46A

107mv is across the meter at an estimated full scale of the new meter, and this is .5A

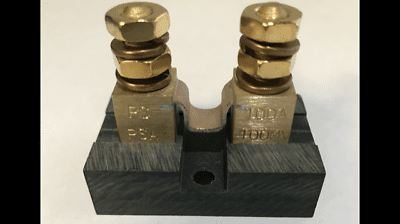

Now, commercial shunts are available for various mv ranges. On egag, I found a couple of 100A, 100mv shunts for about 16 and about 24.00US. In the same price range, found at least one 50A, 100mv shunt

And what would you do with these? Move the ammeter wires outside into the engine bay and mount the shunt out there, eliminating the big ammeter and the bulhead terminals. Then run parallel no10's back into the interior for the power feed. This will relieve the strain on the feed, because THE CHARGING CURRENT no longer goes into the interior

BUT YOU WOULD NOT HAVE to use such as one of these----you could rework the wiring to mimic a 76 A and use the main wiring itself for the shunt, the way GM, Ford, and Chrysler did

A quick search on ebay shows that this was a "mixed bag" through the years. I've known, by looking at electrical diagrams, that some models of the C barges started in early 70's with external shunt. But it turns out this was not a "sure thing" and that Ma sort of "skipped around"

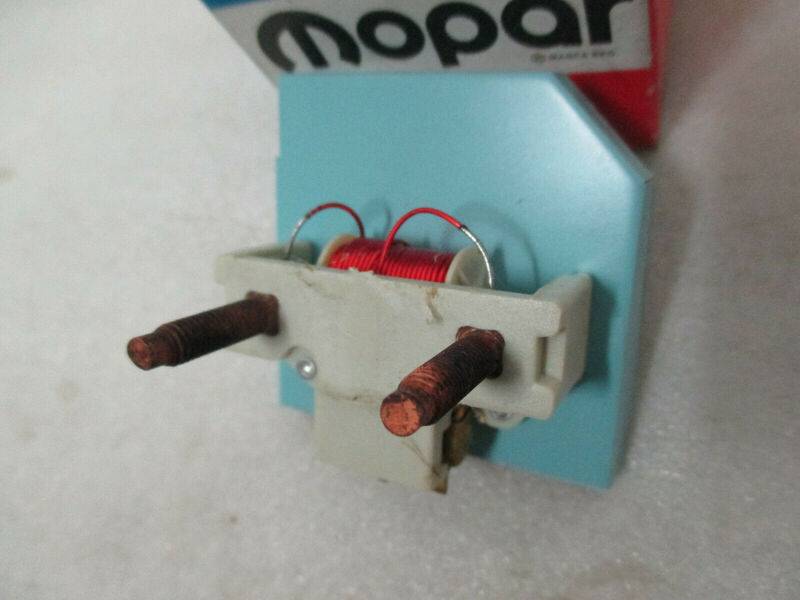

Now you have to be "on your game". Some of these have dramatically higher asking prices than others, and as I said earlier, Ma kinda skipped around. YOU WANT TO LOOK for a photo that shows the "guts" and look for a coil of smaller wire like this:

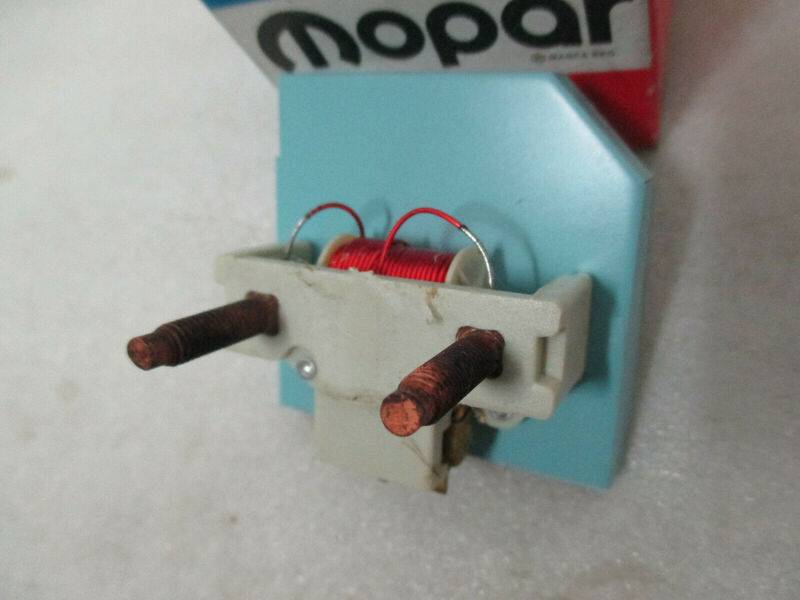

This one below was advertised for a 75 Fury/ Coronet, and I cannot tell. It SEEMS to be an external shunt device, but not sure

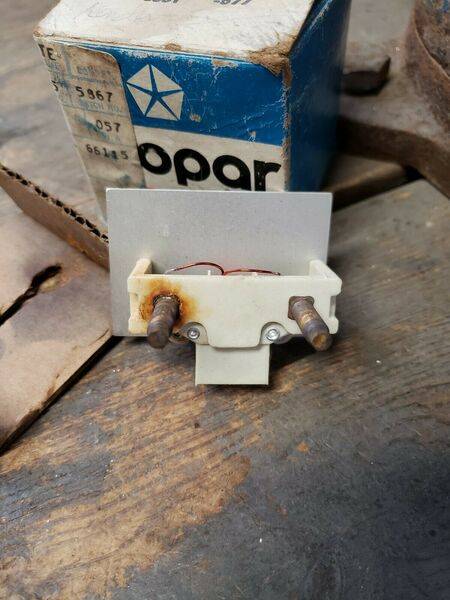

This one below is shown as 71-73 Fury/Monaco/ Polara and there is no doubt that it is what we are looking for "electrically"

NOW YOU SAY but but bu.....b.b.b.b..bb.b.b. BUT "It won't fit my xxxx A body!!"

So, simple, go read the conversion thread, and pull the guts out of the "new" meter and adapt it to your old face, and rework the stud holes if necessary, and go to town on it

Ammeter to Voltmeter...who does it?

Now as some of you know, my ribs still hurt (be a year Aug 15th) and I am old so I move slower. But my plan is to use the 74 roof-fixed Scamp as a "test bed" when I get the time. This will not be an "install" but rather a working emperical experiment to see 'what works'

Why? Because if you REALLY want an ammeter, this setup would solve the bulkhead connector and "full current" ammeter failures

Initial tests.............very unscientific, LOL. I simply took one of my good Fluke meters and wired it in series with the new meter, and then wired a second Fluke across the new meter to measure the voltage across it

"Quck" tests show that

100mv (millivolts) is across the meter and the system is drawing about .46A

107mv is across the meter at an estimated full scale of the new meter, and this is .5A

Now, commercial shunts are available for various mv ranges. On egag, I found a couple of 100A, 100mv shunts for about 16 and about 24.00US. In the same price range, found at least one 50A, 100mv shunt

And what would you do with these? Move the ammeter wires outside into the engine bay and mount the shunt out there, eliminating the big ammeter and the bulhead terminals. Then run parallel no10's back into the interior for the power feed. This will relieve the strain on the feed, because THE CHARGING CURRENT no longer goes into the interior

BUT YOU WOULD NOT HAVE to use such as one of these----you could rework the wiring to mimic a 76 A and use the main wiring itself for the shunt, the way GM, Ford, and Chrysler did

A quick search on ebay shows that this was a "mixed bag" through the years. I've known, by looking at electrical diagrams, that some models of the C barges started in early 70's with external shunt. But it turns out this was not a "sure thing" and that Ma sort of "skipped around"

Now you have to be "on your game". Some of these have dramatically higher asking prices than others, and as I said earlier, Ma kinda skipped around. YOU WANT TO LOOK for a photo that shows the "guts" and look for a coil of smaller wire like this:

This one below was advertised for a 75 Fury/ Coronet, and I cannot tell. It SEEMS to be an external shunt device, but not sure

This one below is shown as 71-73 Fury/Monaco/ Polara and there is no doubt that it is what we are looking for "electrically"

NOW YOU SAY but but bu.....b.b.b.b..bb.b.b. BUT "It won't fit my xxxx A body!!"

So, simple, go read the conversion thread, and pull the guts out of the "new" meter and adapt it to your old face, and rework the stud holes if necessary, and go to town on it

Ammeter to Voltmeter...who does it?

Now as some of you know, my ribs still hurt (be a year Aug 15th) and I am old so I move slower. But my plan is to use the 74 roof-fixed Scamp as a "test bed" when I get the time. This will not be an "install" but rather a working emperical experiment to see 'what works'