After my 5.9 Magnum swap I noticed the carburetor throttle is not opening all the way. The car runs great and shifts great the way I adjusted the linkage. When I shorten the rod, I don't get enough throttle pressure and the transmission slips.

I have the early style solid rod with the bracket on the back of the head. Before the swap I had a 66 transmission, now I have a 74. Maybe throttle pressure is different on the later model transmission??

I adjusted linkage per the FSM but it's still not enough pressure. When I lengthen the rods, the throttle won't open all the way.

Anyone run into this before? Any ideas?

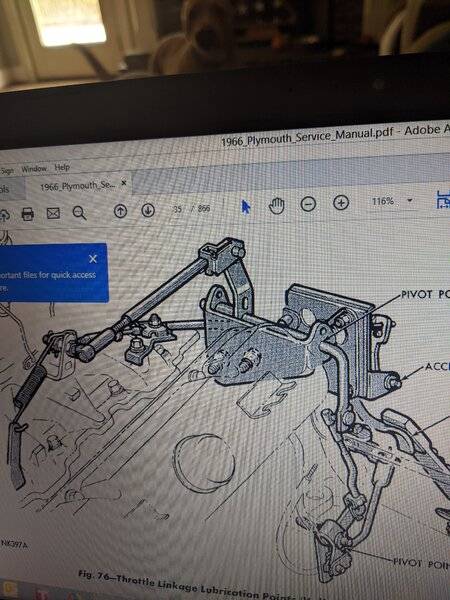

Here's the style I have.

I have the early style solid rod with the bracket on the back of the head. Before the swap I had a 66 transmission, now I have a 74. Maybe throttle pressure is different on the later model transmission??

I adjusted linkage per the FSM but it's still not enough pressure. When I lengthen the rods, the throttle won't open all the way.

Anyone run into this before? Any ideas?

Here's the style I have.