Then on your Transgo II shift kit install. Did you do the Valve Body work yourself and go through the worksheets and set things up as recommended for your model of transmission, Drilling and All ?

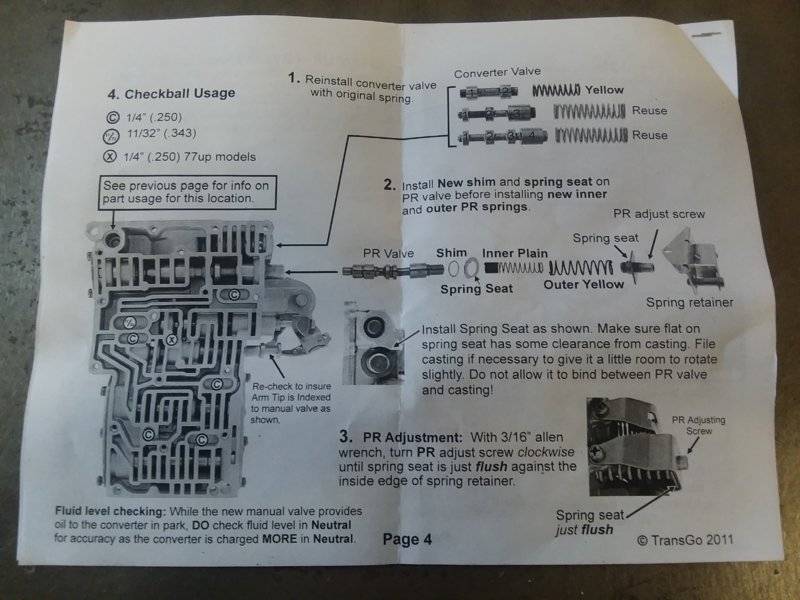

Here is one thing that may affecting your delayed shifts, Check your PR Adjustment, like in the lower left corner of this Transgo Worksheet.

I adjusted my Baseline Transgo Reprogramed Valve Body with the PR Adjusting Screw, Seat Spring Just Flush, same as in this picture. I went conservative on the drilling of the Separator Plate. Everything worked great, Pumped Fluid in Park and In Neutral, and nice shifts to, nothing erratic. Basically a stock setup 318 4bbl / 727, but I did have my Mopar Kickdown Linkage set up properly.

1800 rpm at 65 mph with the 2.94 gears. Very happy with that, low end torque engine of '69, open up the 4 barrels and pulls just great at any speed.

Here is one thing that may affecting your delayed shifts, Check your PR Adjustment, like in the lower left corner of this Transgo Worksheet.

I adjusted my Baseline Transgo Reprogramed Valve Body with the PR Adjusting Screw, Seat Spring Just Flush, same as in this picture. I went conservative on the drilling of the Separator Plate. Everything worked great, Pumped Fluid in Park and In Neutral, and nice shifts to, nothing erratic. Basically a stock setup 318 4bbl / 727, but I did have my Mopar Kickdown Linkage set up properly.

1800 rpm at 65 mph with the 2.94 gears. Very happy with that, low end torque engine of '69, open up the 4 barrels and pulls just great at any speed.