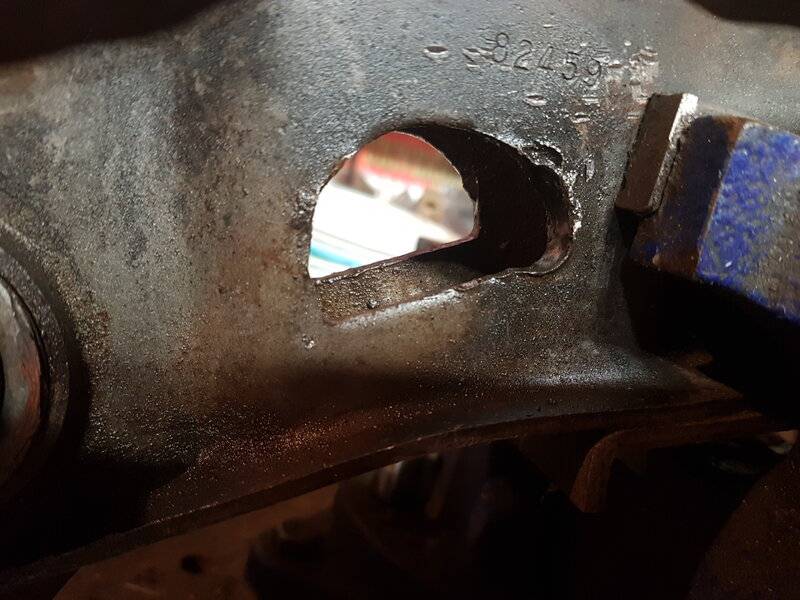

I noticed when welding stiffening plates on the pass side torsion bar adjuster slot is oblong. Can I weld to build up and grind smooth? It's on both sides of passenger lca.

Thanks

Steve

Thanks

Steve