zakimodo

Well-Known Member

Hi All

Just rebuilt and installed my first 8 3/4. On the test/ break in drive, I noticed a few things.

Here is what I am working with

-489 case

-3.55 gears from Yukon (rebuild kit from them as well)

-Eaton Tru Trac

-Ratech crush sleeve eliminator

1. Under ~60 MPH the gears were quiet (car is noisy but I didn't notice any unusual gear noise. Over this speed and with the car in gear I noticed a humming noise (Felt more like harmonics than anything). If I put the car in neutral to coast it got quiet again

2. On my return trip, I started to notice a lot of gear whine when coasting to a stop.

When I set this up, I had a tough time getting the pinion preload set. At first, I could hit preload with only 90Ft lbs of torque on the pinion nut. A thinner shim would all but lock the pinion up at the same torque. I ended up filing an honing down the pinion spacer and was able to get 175 ft/lbs of torque on the pinion nut w/ the correct preload. I left it at this with some blue Loctite. Looking back, I was losing patience with constantly reinstalling the pinion to get this set... All that said, I feel like I screwed up on the preload (nut loosened up or the bearing cups settled). So, am I thinking correctly, is there anything else I should look at once I have a chance to pull the 3rd member out?

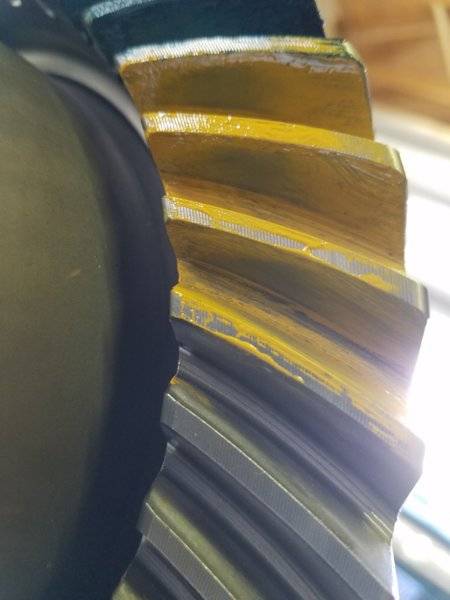

Just for reference, here is my contact pattern after final assembly.

Just rebuilt and installed my first 8 3/4. On the test/ break in drive, I noticed a few things.

Here is what I am working with

-489 case

-3.55 gears from Yukon (rebuild kit from them as well)

-Eaton Tru Trac

-Ratech crush sleeve eliminator

1. Under ~60 MPH the gears were quiet (car is noisy but I didn't notice any unusual gear noise. Over this speed and with the car in gear I noticed a humming noise (Felt more like harmonics than anything). If I put the car in neutral to coast it got quiet again

2. On my return trip, I started to notice a lot of gear whine when coasting to a stop.

When I set this up, I had a tough time getting the pinion preload set. At first, I could hit preload with only 90Ft lbs of torque on the pinion nut. A thinner shim would all but lock the pinion up at the same torque. I ended up filing an honing down the pinion spacer and was able to get 175 ft/lbs of torque on the pinion nut w/ the correct preload. I left it at this with some blue Loctite. Looking back, I was losing patience with constantly reinstalling the pinion to get this set... All that said, I feel like I screwed up on the preload (nut loosened up or the bearing cups settled). So, am I thinking correctly, is there anything else I should look at once I have a chance to pull the 3rd member out?

Just for reference, here is my contact pattern after final assembly.

. It comes in @ ~45mph and is gone by 50. Outside of this you cant hear the rear gears at all.

. It comes in @ ~45mph and is gone by 50. Outside of this you cant hear the rear gears at all.