I'm working on rebuilding a set of original K/H disc brakes on my 1970 Dart. In replacing the wheel bearings I found that one of the outer bearing races was loose in the hub - I could take my fingers and move it around in the hub. I got a new bearing and race and installed that race and had the same results. It is tight as I drive the race in, but when it gets into place it is loose - I can turn it and can wiggle it up and down a little bit. Is this hub toast? Is there a way to fix this hub?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

loose bearing race - K/H disc hub

- Thread starter str12-340

- Start date

-

You can take a center punch & put some dimples in the race area to tighten it up, personally I'd replace it but that's just me.

I'm assuming that K/H hubs are not available new?

my68barracuda

Well-Known Member

Loctite has a product that is made for the exact issue that you are working with.I'm working on rebuilding a set of original K/H disc brakes on my 1970 Dart. In replacing the wheel bearings I found that one of the outer bearing races was loose in the hub - I could take my fingers and move it around in the hub. I got a new bearing and race and installed that race and had the same results. It is tight as I drive the race in, but when it gets into place it is loose - I can turn it and can wiggle it up and down a little bit. Is this hub toast? Is there a way to fix this hub?

Do a search for Loctite 660

That would indictate that the bearing spun in the hub. EDIT: Or as noted later in this thread the hub has a crack

I would try to find a replacement.

A machine shop could machine it larger and make you a hand full of sleeves that would press fit into the hub allowing for a propper press fit of the bearing race.

The reason I suggest making a hand full of sleeves is they might come out with the cone should you need to replace it in the future.

I would try to find a replacement.

A machine shop could machine it larger and make you a hand full of sleeves that would press fit into the hub allowing for a propper press fit of the bearing race.

The reason I suggest making a hand full of sleeves is they might come out with the cone should you need to replace it in the future.

Last edited:

Do What Demonracer says, by center punching dimples all around the race surface in the hub, and then locktiteing the race back in the hub.You can take a center punch & put some dimples in the race area to tighten it up, personally I'd replace it but that's just me.

Works great.

Been doing that for 30 years.

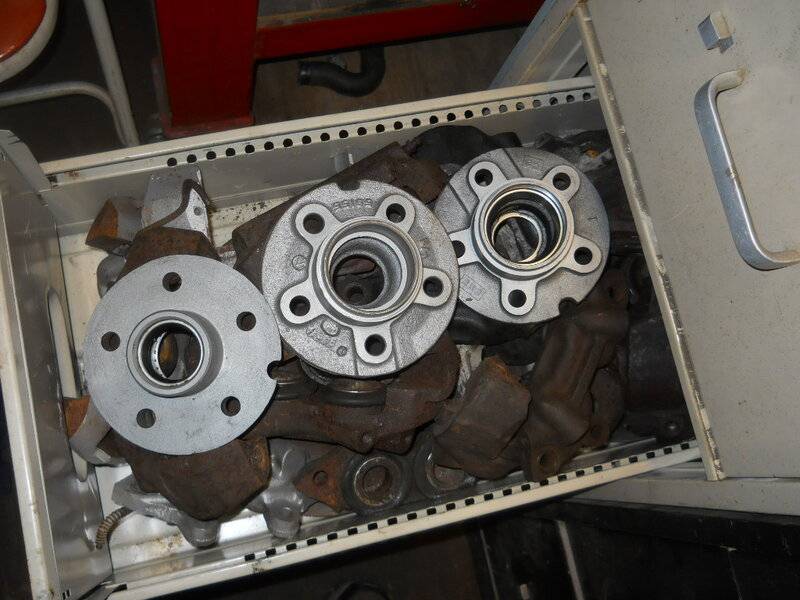

Have it fixed at a machine shop. spray weld it and remachine to size. East Peasy. . Or you can buy a hub . There are 2 different styles for small bolt. A picture would be good to see what you have. I believe I have both styles. You can also switch to 4 1/2 bolt circle using 68 mustang rotors

You can do that if it is not a rotating part. or a lawn and Garden tractor never going over 10 MPH. But How would you know if the punch marks are even and the race is centered and run out is true. This should be fixed and then trued in a precision latheDo What Demonracer says, by center punching dimples all around the race surface in the hub, and then locktiteing the race back in the hub.

Works great.

Been doing that for 30 years.

Do what you want.You can do that if it is not a rotating part. or a lawn and Garden tractor never going over 10 MPH. But How would you know if the punch marks are even and the race is centered and run out is true. This should be fixed and then trued in a precision lathe

Personal preference in the long run.

Worked great for me in the 30 years that i was wrenching.

Your not building the next generation of the Martian Rover.

slickchick

pedal cars only

Ouch !!!!!

my68barracuda

Well-Known Member

You can do that if it is not a rotating part. or a lawn and Garden tractor never going over 10 MPH. But How would you know if the punch marks are even and the race is centered and run out is true. This should be fixed and then trued in a precision lathe

Tell me how you shave your tires to get then round within .010? And then keep then there.

And while at that, tell me how the mechanical fit of the tire-wheel to the axel hub using a non precision center register and five conical acorn nuts that are tightened against studs that are basically sweged into a weather exposed steel plate, consistently perfectly centers the tire-wheel assembly to the hub.

Last edited:

my68barracuda

Well-Known Member

Loctite has a product that is made for the exact issue that you are working with.

Do a search for Loctite 660

For the Loctite 660 to work well I am sure all mating surfaces would need to be dry and clean.

The link below has Technical and Customer Service Hotline phone numbers, I am sure they would walk you through the best way to use the product to fix the issue with the loose race.

Contact (loctiteproducts.com)

Tell me how you shave your tires to get then round within .010? And then keep then there.

And while at that, tell me how the mechanical fit of the tire-wheel to the axel hub using a non precision center register and five conical acorn nuts that are tightened against studs that are basically sweged into a weather exposed steel plate, consistently perfectly centers the tire-wheel assembly to the hub.

You can do what ever you want. Use elmers glue for all I care. The rotor and hub gets warm and the product your using may get soft with heat. Why take the chance? Fix the hub correctly. What you are suggesting is a bandage that if it does get soft will work its way into the bearing.

Then what? Let it hammer around in there some more. Some people are OK with glueing and doing what ever they can to get buy. I am only suggesting the way I would fix it and the reason why. < Poet and didn't know it

As far as truing the hub to prevent wobble . The more you move to the outside of a diameter the greater it gets. .010 can become 1/8 inch pretty quick side to side

As far as grinding tires? It can be done but not to true them. We would do it on Hoosier's all the time on the atv national races. Take all the rubber off we could to reduce weight and increase torque for the feature's. We won a lot of races reducing reciprocating weight. Regroove them so no one would know ATV's and the sprint car

We have a machine shop. I can't be telling people to glue their parts on there cars. There is only one way to do things when you are in business. Could you imagine what customers would say if we told them don't worry the glue will hold up just fine.

I already offered the OP a hub in a PM . He is getting it apart to see what one he has. Its a wheel hub on a performance car for gods sake. You hit the brakes on a 8 -9 second car you don't want to wonder if the glue will hold up. It may but some people don't want to chance it. Did you price loctite lately.

Good luck with your build. LOL

Another option is to machine the inside of the hub up to the next OD size race and keep the ID the same.

Another option is to machine the inside of the hub up to the next OD size race and keep the ID the same.

That is an interesting idea. So you are saying that there may be oversized races that still take an A-2 bearing? How would you find such a thing?

No. I'm saying there ARE larger races that take the A2. You need to get into a Timken or National bearing book and look by OD and ID.That is an interesting idea. So you are saying that there may be oversized races that still take an A-2 bearing? How would you find such a thing?

my68barracuda

Well-Known Member

OldmanMopar

Mentioning this for your information and education

Loctite is not “glue”.

Each Loctite product has a heat saturation point at which it will melt and release. That is so the parts held together with Loctite can be disassembled.

The Loctite 660 is made specifically to fix bearing races that are no longer a tight locked fit into their bores.

As such I would expect that it would survive in an automotive wheel bearing application. Typically I would expect the max temperature at a wheel bearing to be 200F If your wheel bearings are running in excess of 500 F so you begin to worry about the Loctite releasing, you will bigger problems than that.

Concerning the cost of Loctite, and you should know the answer to this, have you looked at the cost of precision machining lately?

Honestly I am a bit surprised that a person with your racing and machine shop experience is not already familiar with Loctite products.

Mentioning this for your information and education

Loctite is not “glue”.

Each Loctite product has a heat saturation point at which it will melt and release. That is so the parts held together with Loctite can be disassembled.

The Loctite 660 is made specifically to fix bearing races that are no longer a tight locked fit into their bores.

As such I would expect that it would survive in an automotive wheel bearing application. Typically I would expect the max temperature at a wheel bearing to be 200F If your wheel bearings are running in excess of 500 F so you begin to worry about the Loctite releasing, you will bigger problems than that.

Concerning the cost of Loctite, and you should know the answer to this, have you looked at the cost of precision machining lately?

Honestly I am a bit surprised that a person with your racing and machine shop experience is not already familiar with Loctite products.

Last edited:

Any product can work, engine overhaul chemicals may work, but at some point you just have to do a real repair or replacement.Honestly I am a bit surprised that a person with your racing and machine shop experience is not already familiar with Loctite products

I'm with oldmanmopar repair it correctly or replace it. If it has spun so much that it can be spun by hand in it's bore I would not rely on anything but a propper mechanical connection.

Replace it with what? Another possible bad hub? There are no new ones.

I am more familiar with loctite products then you realize. The term glue was as sarcastic as your comments. The cost of machining doesn't cost me anything but a "that a boy" now and then. But that is either here nor there.OldmanMopar

Mentioning this for your information and education

Loctite is not “glue”.

Each Loctite product has a heat saturation point at which it will melt and release. That is so the parts held together with Loctite can be disassembled.

The Loctite 660 is made specifically to fix bearing races that are no longer a tight locked fit into their bores.

As such I would expect that it would survive in an automotive wheel bearing application. Typically I would expect the max temperature at a wheel bearing to be 200F If your wheel bearings are running in excess of 500 F so you begin to worry about the Loctite releasing, you will bigger problems than that.

Concerning the cost of Loctite, and you should know the answer to this, have you looked at the cost of precision machining lately?

Honestly I am a bit surprised that a person with your racing and machine shop experience is not already familiar with Loctite products.

The only way I would ever fix something the way you suggested is on a beater car for a quick temporary fix to get down the road for a work car. And then I probably would throw the old bearings back in until I found a hub

You don't fix a classic or muscle car that you take pride in that way. Spend the money and be confident and proud of your repair. So in the future when you sell the car people won't think poorly of your workmanship.

Yes!Replace it with what? Another possible bad hub? There are no new ones

There are hubs out there, I would not buy an east coast hub high probability of excessive rust.

There is also the mustang hub and disk that can be modified to fit and gain 5x4.5 bbp

Nobody asked how much 'wobble' the race has. If it has been loose for a long time, there could be a lot of wear. And how would you measure it? If wear is considerable, then three problems present.

- how well will Loc seal a large gap, if it can at all

- how do you centre the race in a hole that could have worn to an oval shape

- runout at the disk pad surface. Off centre 0.005" at the race might be 0.020" or more where the pads apply, giving a pulsating brake pedal.

Get the hub properly machined to take a spacer...or get a new hub.

- how well will Loc seal a large gap, if it can at all

- how do you centre the race in a hole that could have worn to an oval shape

- runout at the disk pad surface. Off centre 0.005" at the race might be 0.020" or more where the pads apply, giving a pulsating brake pedal.

Get the hub properly machined to take a spacer...or get a new hub.

There are no new hubs. Just different ones.Nobody asked how much 'wobble' the race has. If it has been loose for a long time, there could be a lot of wear. And how would you measure it? If wear is considerable, then three problems present.

- how well will Loc seal a large gap, if it can at all

- how do you centre the race in a hole that could have worn to an oval shape

- runout at the disk pad surface. Off centre 0.005" at the race might be 0.020" or more where the pads apply, giving a pulsating brake pedal.

Get the hub properly machined to take a spacer...or get a new hub.

I like the spray welding idea. Besides a good used hub, that's probably the best bet, besides a good hub. Not everybody has access to that though and sometimes you have to do it different ways. I can also relate to someone not wanting to change to the larger bolt pattern.

Lastly, just spitballin here, has anyone looked at the drum brake hub to see if it can be modified to work? That would at least give us more hubs to choose from before they're all gone. ......and they will be all gone one day.

Lastly, just spitballin here, has anyone looked at the drum brake hub to see if it can be modified to work? That would at least give us more hubs to choose from before they're all gone. ......and they will be all gone one day.

For those that want accurate information on Loctite 660, the data sheet can be found here https://www.henkel-adhesives.com/us/en/product/retaining-compounds/loctite_660.html

It's also $11.99 for a tube, so I'm not sure what the "have you seen loctite prices" thing is about. $12 is a lot less than a spray weld and machine work will cost.

https://www.amazon.com/dp/B000O03DK0/?tag=fabo03-20

Loctite 660 was literally designed to repair worn parts without remachining, specifically keyways and bearing races. So it's perfectly suited for repairing a worn hub for a bearing race. It was designed for gaps up to .02", so, that would mean the outer diameter of the race could be .04" smaller in diameter than the inside of the hub and Loctite 660 would still work. It's release temperature is 250° C, so, that's 482°F. If your bearing race hits 482°F you have a serious problem. High temp wheel bearing grease will boil around 450°F and has an ignition temp of ~500°F.

So as long as your hub/race clearance is within the specs of the Loctite 660, that's a perfectly viable repair. Spray welding and machining the hub would be a more permanent solution, but even the spray welding process doesn't create the same product as when the hub was new. It's still a repair involving different materials than the original metal. It also has a range of acceptable uses, just like the Loctite. And you can sleeve the hub too, but in that case you have two places where things can fail, at the race to the spacer and at the spacer to the hub. Done correctly it shouldn't ever be an issue, but regardless it's another place for potential issues. Bottom line is use a repair that's suited for the amount of wear you have. Even a brand new hub can spin a bearing race if it's not toleranced correctly.

Of course you could always go to 73+ disks which have the hubs integrated into the rotors, so, new hubs with every set of rotors and if you spin a race you just buy a new rotor. But that's a complete brake conversion.

Also, just some trivia for those that don't know, but truing tires was a common practice for bias ply tires. The manufacturing process of bias ply tires frequently meant they were out of round, and shaving them down to be true was something most tire shops used to be able to do. Radial tires generally don't need this and typically only racers shave their radial tires, but it's not to true them, it's to reduce weight and tread depth for better performance.

Truing bias ply tires

Truing Bias-Ply Tires - Street Rodder Magazine

Shaving tires for autoX

https://www.tirerack.com/tires/tiretech/techpage.jsp?techid=67

It's also $11.99 for a tube, so I'm not sure what the "have you seen loctite prices" thing is about. $12 is a lot less than a spray weld and machine work will cost.

https://www.amazon.com/dp/B000O03DK0/?tag=fabo03-20

Loctite 660 was literally designed to repair worn parts without remachining, specifically keyways and bearing races. So it's perfectly suited for repairing a worn hub for a bearing race. It was designed for gaps up to .02", so, that would mean the outer diameter of the race could be .04" smaller in diameter than the inside of the hub and Loctite 660 would still work. It's release temperature is 250° C, so, that's 482°F. If your bearing race hits 482°F you have a serious problem. High temp wheel bearing grease will boil around 450°F and has an ignition temp of ~500°F.

So as long as your hub/race clearance is within the specs of the Loctite 660, that's a perfectly viable repair. Spray welding and machining the hub would be a more permanent solution, but even the spray welding process doesn't create the same product as when the hub was new. It's still a repair involving different materials than the original metal. It also has a range of acceptable uses, just like the Loctite. And you can sleeve the hub too, but in that case you have two places where things can fail, at the race to the spacer and at the spacer to the hub. Done correctly it shouldn't ever be an issue, but regardless it's another place for potential issues. Bottom line is use a repair that's suited for the amount of wear you have. Even a brand new hub can spin a bearing race if it's not toleranced correctly.

Of course you could always go to 73+ disks which have the hubs integrated into the rotors, so, new hubs with every set of rotors and if you spin a race you just buy a new rotor. But that's a complete brake conversion.

Also, just some trivia for those that don't know, but truing tires was a common practice for bias ply tires. The manufacturing process of bias ply tires frequently meant they were out of round, and shaving them down to be true was something most tire shops used to be able to do. Radial tires generally don't need this and typically only racers shave their radial tires, but it's not to true them, it's to reduce weight and tread depth for better performance.

Truing bias ply tires

Truing Bias-Ply Tires - Street Rodder Magazine

Shaving tires for autoX

https://www.tirerack.com/tires/tiretech/techpage.jsp?techid=67

-