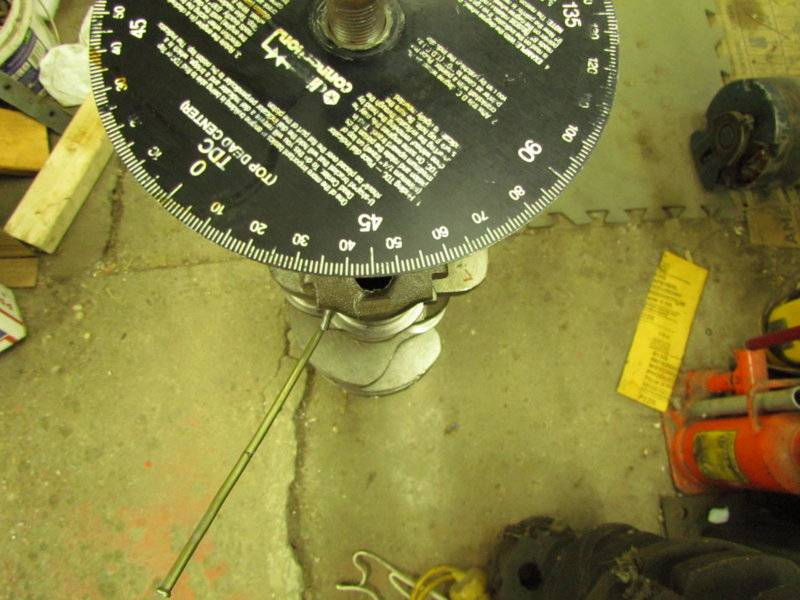

I have been playing around and this is what I came up with, Using a degree wheel loose so it would spin so that 90* marks would indicate the bottom of the block crank center line. Using nm9stheham

degree's of 75* for 3.31 stroke I was able to get an Idea where the oil hole would have to be @ 55* and 75* I put 2 rods through the oil holes on #1 & 2 journals the silver is the main and the yellow color is the rod.

degree's of 75* for 3.31 stroke I was able to get an Idea where the oil hole would have to be @ 55* and 75* I put 2 rods through the oil holes on #1 & 2 journals the silver is the main and the yellow color is the rod.