You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Lower Rear Quarter Patch Repair

- Thread starter adamm

- Start date

-

adamm

Well-Known Member

I have yet to explore the wheel well fully. I know the lip is rusty in a few spots, and I'm willing to bet there are some sections I'll need to patch, at the very least on the bottom front.

Any tips?

Any tips?

adamm

Well-Known Member

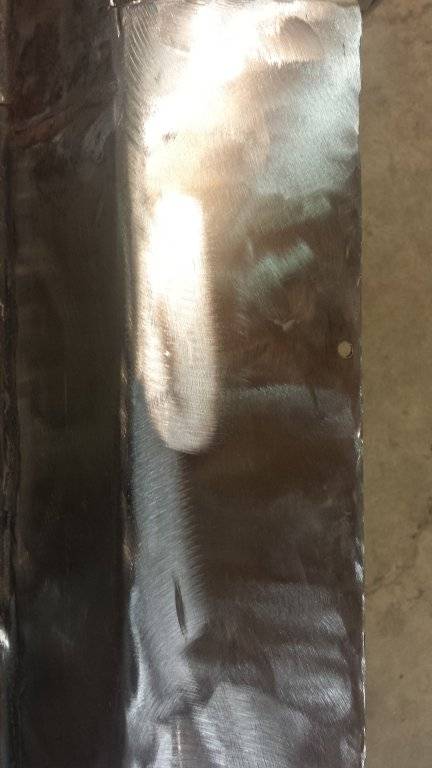

Was able to play with the project today a bit more. Inner rocker patch fir the passenger side done along with some cleaning to the drivers side outer.

GeorgeH

Well-Known Member

I know your not done with your prep so just throwing this out there, You should be using something in between those patches to afford some type of corrosion protection. Whether it be epoxy prime and just clean up enough to weld and some weld-prime etc inside and out of each layer. I like vice grips or sheet metal screws over the spring clamps. Tighter fit up easier to weld and less chance of bumping something out of place when you can't see through a helmet.

Just in general, if your repairing or making patches you want to use the same gauge material as you are replacing. You do not want to use pieces of an 18-20g aftermarket qtr. patch panel to repair a 14-16g. structural inner rocker as was suggested.

Just in general, if your repairing or making patches you want to use the same gauge material as you are replacing. You do not want to use pieces of an 18-20g aftermarket qtr. patch panel to repair a 14-16g. structural inner rocker as was suggested.

Last edited:

GeorgeH

Well-Known Member

16gI have yet to explore the wheel well fully. I know the lip is rusty in a few spots, and I'm willing to bet there are some sections I'll need to patch, at the very least on the bottom front.

Any tips?

adamm

Well-Known Member

I know your not done with your prep so just throwing this out there, You should be using something in between those patches to afford some type of corrosion protection. Whether it be epoxy prime and just clean up enough to weld and some weld-prime etc inside and out of each layer. I like vice grips or sheet metal screws over the spring clamps. Tighter fit up easier to weld and less chance of bumping something out of place when you can't see through a helmet.

Just in general, if your repairing or making patches you want to use the same gauge material as you are replacing. You do not want to use pieces of an 18-20g aftermarket qtr. patch panel to repair a 14-16g. structural inner rocker as was suggested.

Thank you! That's very reassuring as I'm figuring this out on the go (of course with research). I used some 11g flat stock for the inner rocker patch as I couldn't find any 14/16; you think that's ok?

Good point on the spring clamps, and I will use butt weld clamps once it's roughed in better. The spring clamps are nice for quick use.

I'll be sure to protect all the pieces with primer and paint once ready; I don't want to ever have to work on these areas again!

Redid the drivers side rocker patch this weekend.

adamm

Well-Known Member

Nice progress so far. How's the part of the wheel well that the seat belt stud is attached to?

The drivers side is solid! I was happy to find that out. I will need to replace the bottom few inches of the wheel well in front of the rear tire, and the lip of it about 1/4 way up. I might try to shape my own replacement due to how small of a patch I need. Worst case scenario I'm out a few bucks but at least tried.

adamm

Well-Known Member

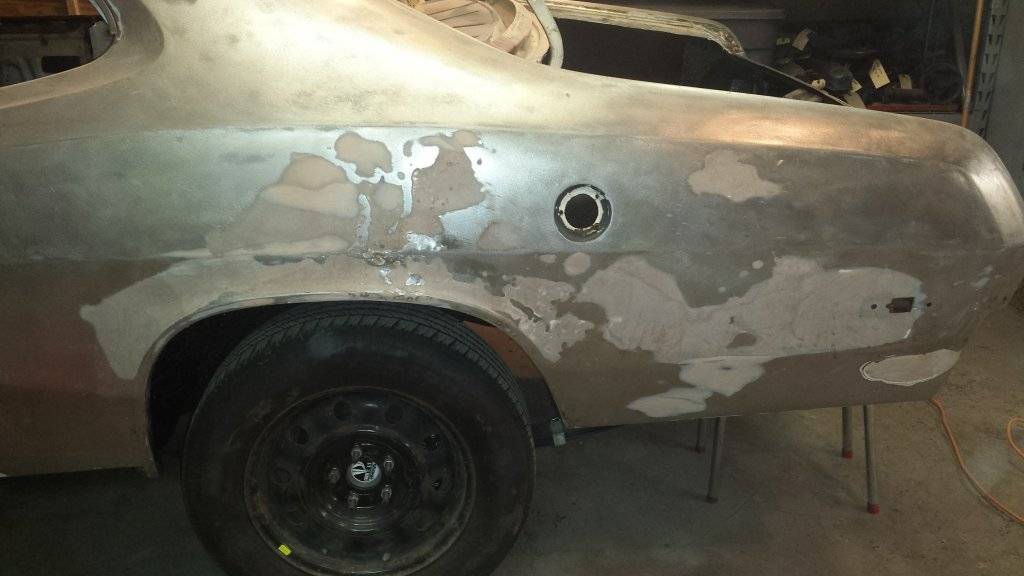

Cut out a section of the quarter and lip of the wheel well today. I think this is the last I had to cut on my drivers side and can start prepping for primer and welding.

Adamm- With all the work you are going thru with patches and the old filler left behind from previous work- and I understand cost is an issue... a full quarter would had actually been easier, less work over all and you could had gotten inside and sandblasted or wire wheeled to get the rust out. The last picture the inner wheel well looks like it has deep cancer(the dark brown spots)

As a welder and someone putting quarters on my 66' as we speak- I tell you parts are way harder than if a whole quarter was available.

Also use some sort of weld thru galvi primer or something to protect that new metal as just paint will burn up in welding.

I give you alot of credit for just diving in. Good job!

Joe

As a welder and someone putting quarters on my 66' as we speak- I tell you parts are way harder than if a whole quarter was available.

Also use some sort of weld thru galvi primer or something to protect that new metal as just paint will burn up in welding.

I give you alot of credit for just diving in. Good job!

Joe

GeorgeH

Well-Known Member

Ditto, even a half skin will get you to the top bodyline and you could get rid of the hammered up, packed up mess above and behind where you have cutout. What's the plan for the wheelhouse?

adamm

Well-Known Member

Thank you both! My initial approach has been to cut out the absolute minimum, as I wasn't sure on next steps all the time, or best approach. Each time I talk about this more, and hear the advice, I lean further and further towards a quarter skin. I believe I read that AMD is no longer producing quarters for dart sports, or even some earlier models such as the 71/72, but I've reached out to double check.

I've read mixed reviews on Sherman/Goodmark, so hoping I can nab an AMD piece. Wifey gave me the OK to buy one last night since it's my birthday month, so the hunt begins.

For the wheelhouse, I'd really like to try and make my own patch, even if it doesn't work out. Looking at the pic I posted, the rust does look worse than when I was cutting sections out. A case of beer will do that. I'll dig in again and remove some more after I hit the area with a wire wheel.

I also have a few cans of weld thru primer ready that will get put to use. The paint comment was for after the welding is done, sorry, should have clarified.

Again, I really appreciate the help, and feedback. Couldn't do it without this great Mopar community.

I've read mixed reviews on Sherman/Goodmark, so hoping I can nab an AMD piece. Wifey gave me the OK to buy one last night since it's my birthday month, so the hunt begins.

For the wheelhouse, I'd really like to try and make my own patch, even if it doesn't work out. Looking at the pic I posted, the rust does look worse than when I was cutting sections out. A case of beer will do that. I'll dig in again and remove some more after I hit the area with a wire wheel.

I also have a few cans of weld thru primer ready that will get put to use. The paint comment was for after the welding is done, sorry, should have clarified.

Again, I really appreciate the help, and feedback. Couldn't do it without this great Mopar community.

GeorgeH

Well-Known Member

Thank you both! My initial approach has been to cut out the absolute minimum, as I wasn't sure on next steps all the time, or best approach. Each time I talk about this more, and hear the advice, I lean further and further towards a quarter skin. I believe I read that AMD is no longer producing quarters for dart sports, or even some earlier models such as the 71/72, but I've reached out to double check.

Might be so, one of the guys in the coffee thread was talking about that.

adamm

Well-Known Member

Well, bummer, sounds like AMD is no longer making the quarter skins. Guess I'll have to try and find something 2nd hand for an AMD piece, and start to research other vendors.

Mopar-Man

Big Block Better Burnout

Always get the parts FIRST before you cut anything. Definitely should have done full quarters but I think you know that now.

adamm

Well-Known Member

Always get the parts FIRST before you cut anything. Definitely should have done full quarters but I think you know that now.

The areas I cut out needed to be removed regardless. That's why I stuck with only the minimum to start. But yes, a quarter skin is still in my future, just researching to see which manufacturer is "better" based on community feedback since AMD is no longer producing. I won't be removing any more metal until I have the part in hand and can draw out my areas to cut. I don't think I need a full quarter, the skin should be plenty. Worst case scenario, in my head anyway, is getting a salvage piece. Maybe I'm just being optimistic though!

I've made plenty of mistakes, and "wish I woulda done it this way" moments in hindsight. Being a first timer, I've come into it expecting such, and hoping I don't screw up too much.

Hell, sanding the entire car, top to bottom by hand was shitty; took me all of last spring/summer. A time sink that I'll never get back. If I could go back in time I would have just sent it in to get blasted. Perhaps my next car!

Mopar-Man

Big Block Better Burnout

The areas I cut out needed to be removed regardless. That's why I stuck with only the minimum to start. But yes, a quarter skin is still in my future, just researching to see which manufacturer is "better" based on community feedback since AMD is no longer producing. I won't be removing any more metal until I have the part in hand and can draw out my areas to cut. I don't think I need a full quarter, the skin should be plenty. Worst case scenario, in my head anyway, is getting a salvage piece. Maybe I'm just being optimistic though!

I've made plenty of mistakes, and "wish I woulda done it this way" moments in hindsight. Being a first timer, I've come into it expecting such, and hoping I don't screw up too much.

Hell, sanding the entire car, top to bottom by hand was shitty; took me all of last spring/summer. A time sink that I'll never get back. If I could go back in time I would have just sent it in to get blasted. Perhaps my next car!

Dude, you dove in and I give you respect for that! Don't beat yourself up, you'll be much quicker on the next car.

I can think of two tools right now that will make your life alot easier, clecko's, and a flange tool.

adamm

Well-Known Member

I can think of two tools right now that will make your life alot easier, clecko's, and a flange tool.

Thank you! Just today I was watching some how to's and ran across both of those. I wasnt sure about their use but will definitely start looking for some to buy.

Is it a you get what you pay for tool, or are they all fairly equal and effective?

adamm

Well-Known Member

Made some progress over the weekend. Bought a real solid passenger side rocker replacement from Tony (whitepunkonnitro), cut and cleaned 'er up. Came out real nice and fits like a glove. Pretty satisfying going through it.

I'm going to buy a flange tool and lap weld most of the seams. Will be easier for me.

I'm going to buy a flange tool and lap weld most of the seams. Will be easier for me.

adamm

Well-Known Member

Got quite a bit done the last couple days. Passenger inner and outer fitment is complete and ready to be welded in.

Used the HF pnuematic flange/punch tool and it worked great. Would have liked a bit more of a step, but it'll do. That seems to be a common review of the tool. You can juat make out the flange in one of the pics. It's a bit more than the pic shows. It will however require some body work to smooth out the lap joint prior to paint. Used a 20% off coupon, got it for 31$. Would buy again.

Also cut out what I feel to be the last bit of cancer on my driver side wheel well. I'm toying with the idea of removing the lip when I reassemble as I wanted to roll them anyway. Best time would be now I guess.

Used the HF pnuematic flange/punch tool and it worked great. Would have liked a bit more of a step, but it'll do. That seems to be a common review of the tool. You can juat make out the flange in one of the pics. It's a bit more than the pic shows. It will however require some body work to smooth out the lap joint prior to paint. Used a 20% off coupon, got it for 31$. Would buy again.

Also cut out what I feel to be the last bit of cancer on my driver side wheel well. I'm toying with the idea of removing the lip when I reassemble as I wanted to roll them anyway. Best time would be now I guess.

adamm

Well-Known Member

Got a delivery today, a new AMD quarter!

My dilemma, and I might get flack for this, is that I don't want to do the full quarter, just a skin. So that would mean cutting up the new piece to size. I've done a lot of research and I don't feel that I have the skills nor the tools to do the full quarter properly. As well, a lot of the metal is still good on the original quarter and doesn't need to be cut out.

My question, is where would it give me the best results to make the cut?

I was planning to flange and lap weld, any concerns? I have researched this as well and didn't find any real issues vs. butt welding. Some mentioned this was an easier way actually to control the metal sinking in. Any thoughts/experience is welcome.

I didn't know where to store it, so figured I'd just tie it to the car.

My dilemma, and I might get flack for this, is that I don't want to do the full quarter, just a skin. So that would mean cutting up the new piece to size. I've done a lot of research and I don't feel that I have the skills nor the tools to do the full quarter properly. As well, a lot of the metal is still good on the original quarter and doesn't need to be cut out.

My question, is where would it give me the best results to make the cut?

I was planning to flange and lap weld, any concerns? I have researched this as well and didn't find any real issues vs. butt welding. Some mentioned this was an easier way actually to control the metal sinking in. Any thoughts/experience is welcome.

I didn't know where to store it, so figured I'd just tie it to the car.

GeorgeH

Well-Known Member

I would put the whole qtr on since you have it. Less finish work going across the sail panel verse running a seam all the way down the side of the car. I would build a sleeve for the sail panel joint over trying to flange it.

chryslerfat

Well-Known Member

It is alot less work to do a full 1/4 trust me many hours will be spent blending on a partial and the perfectionist I am when I use a partial I never look at the car the same.

Put the full quarter on. And if you haven't removed the seam sealer from the trunk gutter , do it now. If the gutter is rusted out , you might want to order one of them too. I know , easy to spend someone else's money. Putting just the skin on is very time consuming. You will have a six feet long seam to work. Lots of starts and stops for cooling to minimize warping and it will still probably warp. Then hammer/dolly and filler work on a six foot log seam. Then you have to pretty it up on the inside.

adamm

Well-Known Member

I would put the whole qtr on since you have it. Less finish work going across the sail panel verse running a seam all the way down the side of the car. I would build a sleeve for the sail panel joint over trying to flange it.

Sorry, can you explain a bit more about what you mean by a sleeve for the sail panel joint? I dont know what that is.

-