It's not together yet, but here are the bits and pieces of my 408:

Block is 1970 360, .030 over, square decked to 9.588, line honed, main caps studded, lifter bores bushed.

Scat 4340 crank, Scat H-beam rods, upgraded ARP bolts, Icon 744 pistons, Internal balance.

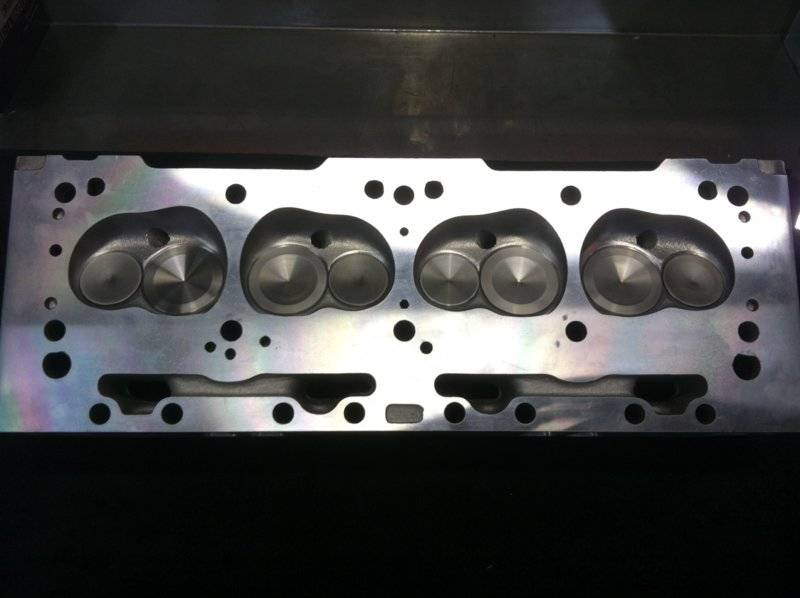

Heads are my Edelbrocks, bought them as "Stage 3" CNC ported back in 08 following is local flow bench after some touch up:

Before After

.300 222.8/137.6 222.0/151.3

.400 258.0/163.7 263.7/194.7

.500 271.1/188.4 280.5/205.8

.550 275.6/198.4 280.5/208.3

.600 278.6/200.8 282.3/208.3

.650 279.3/203.3 284.2/208.3

Chamber volume is 60 cc

Have 2 intakes to choose from, an M1 and a Holley Strip Dominator

Have 2 carbs, 750 DP and an 850 Quick fuel

Cam is a Comp Cams custom grind solid FT:

Duration at .020 297 I and 318 E

Duration at .050 271 I and 280 E

Install at 104 intake center line

Lobe separation 108

Lobe lift is .4200 I and .4050 E

I have 1.6 Hughes roller tip rockers

Block is 1970 360, .030 over, square decked to 9.588, line honed, main caps studded, lifter bores bushed.

Scat 4340 crank, Scat H-beam rods, upgraded ARP bolts, Icon 744 pistons, Internal balance.

Heads are my Edelbrocks, bought them as "Stage 3" CNC ported back in 08 following is local flow bench after some touch up:

Before After

.300 222.8/137.6 222.0/151.3

.400 258.0/163.7 263.7/194.7

.500 271.1/188.4 280.5/205.8

.550 275.6/198.4 280.5/208.3

.600 278.6/200.8 282.3/208.3

.650 279.3/203.3 284.2/208.3

Chamber volume is 60 cc

Have 2 intakes to choose from, an M1 and a Holley Strip Dominator

Have 2 carbs, 750 DP and an 850 Quick fuel

Cam is a Comp Cams custom grind solid FT:

Duration at .020 297 I and 318 E

Duration at .050 271 I and 280 E

Install at 104 intake center line

Lobe separation 108

Lobe lift is .4200 I and .4050 E

I have 1.6 Hughes roller tip rockers

...

...