Keystone

Well-Known Member

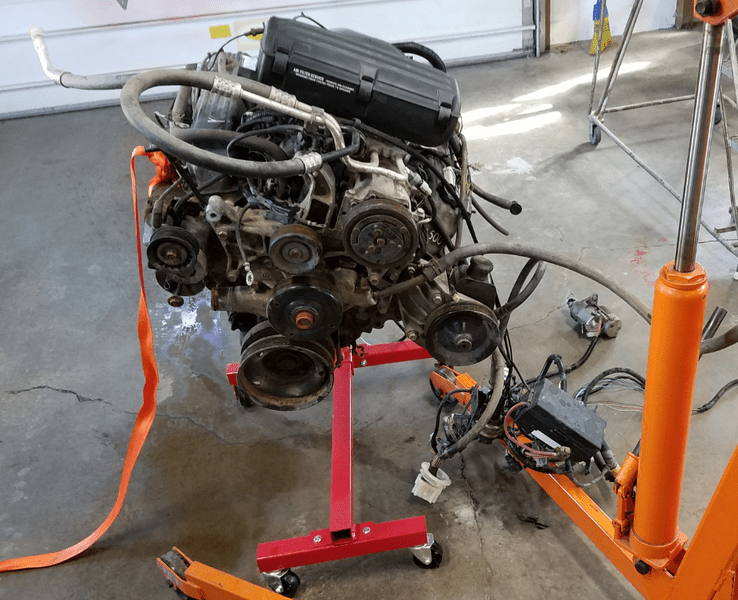

I'm doing my first engine rebuild on a 5.2 Magnum that's going to replace the Slant in my '73 Swinger. Quick backstory, it's out of '96 Ram and I paid $200 for it off of Faceberg Marketplace. It was described as (of course) "running when pulled", but for the price I figured I couldn't go wrong since other than missing the alternator, it was 100% complete.

I was hoping to just clean it up and and re-gasket a few things, but after doing a compression test, the numbers didn't look great.

I misplaced the paper I wrote the figures on, but as I recall they were all in the 100 - 115 psi range. That seemed low, so I decided to tear it down.

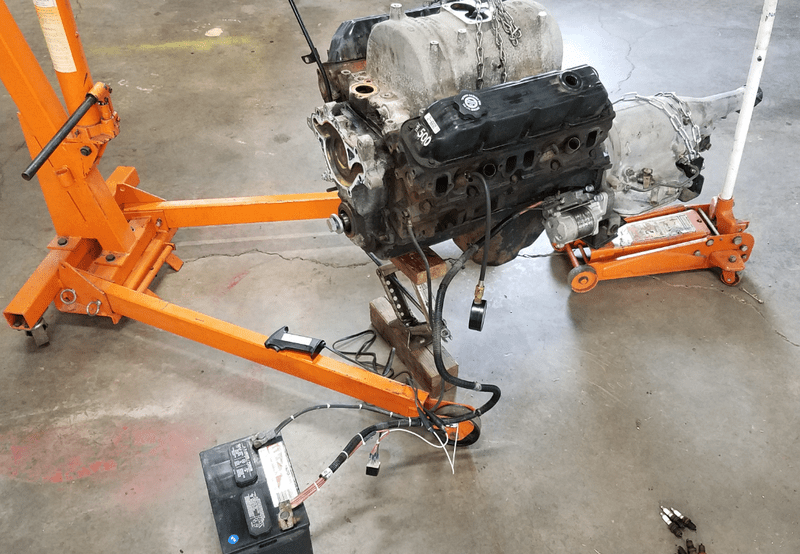

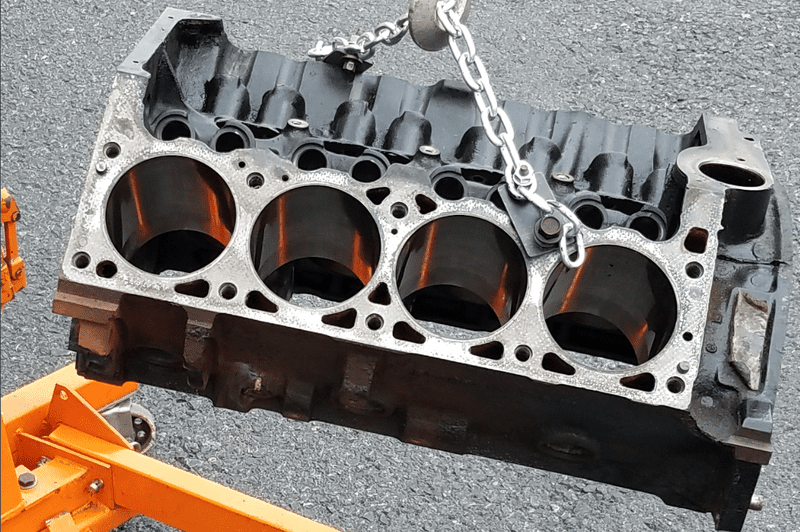

Nothing jumped out at me as being out of the ordinary, except a couple of the cam bearings, which I'll get to in a minute. The cylinders were all smooth, with no noticeable crosshatch, so at the very least they'll need a hone.

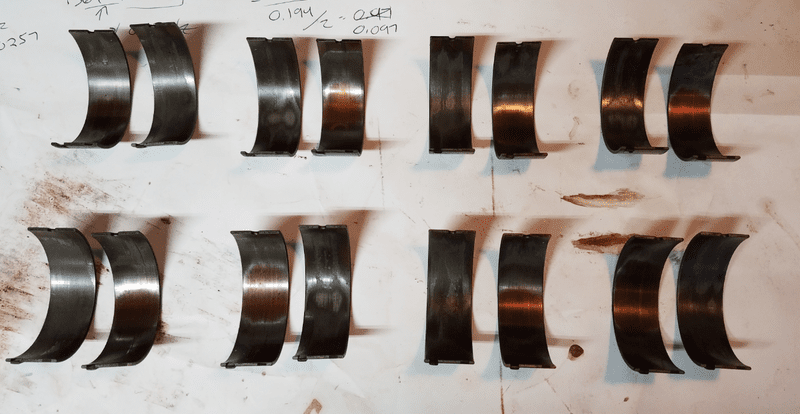

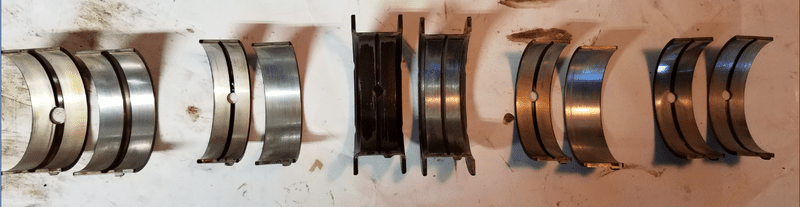

The rod bearings were showing some wear, but didn't look bad. At least I don't think they look terrible.

Same with the crank bearings.

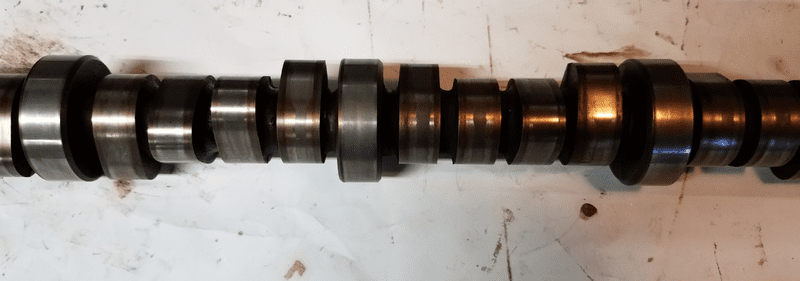

And none of the bearing surfaces on the cam looked bad.

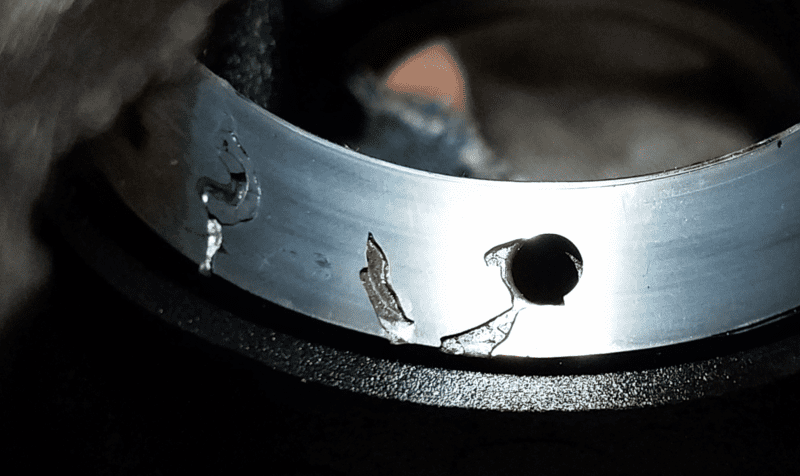

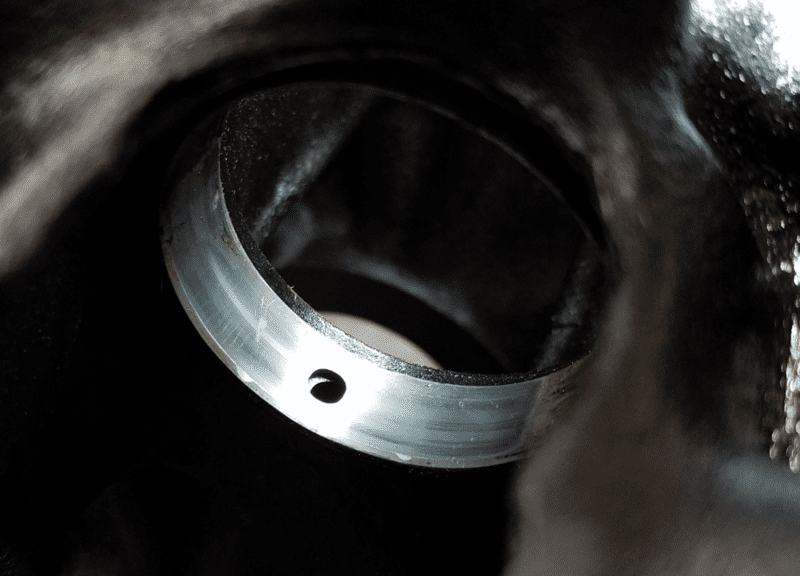

So, what happened to these two cam bearings?

The same bearing but from a different angle and zoomed in

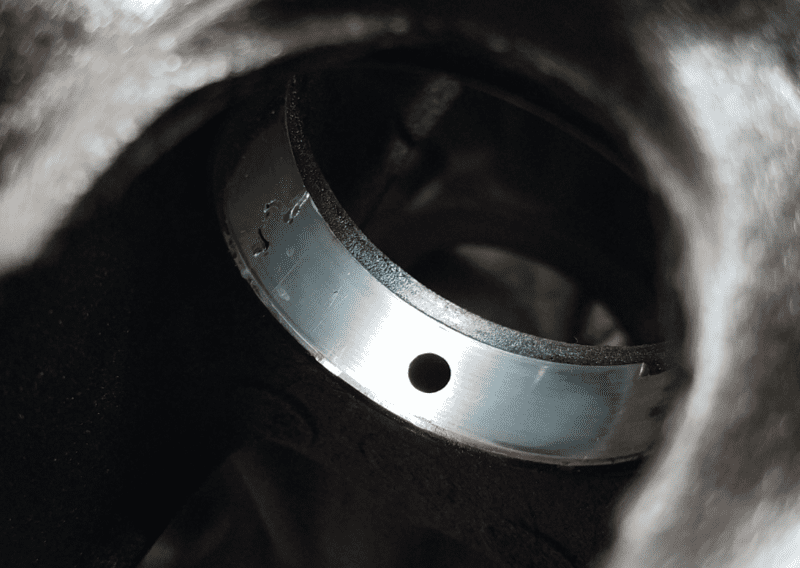

This one isn't as bad, but still messed up

All the others seem fine.

I have the tool and new cam bearings on order, but I want to know if there's anything else I should be looking for since I have no idea what caused this. I'm still hoping to just be able to do a hone and put in a re-ring kit. Again, this is my first rebuild, and I'm sure I'll have more questions as I move forward, but this is definitely one I'd like some input on.

I was hoping to just clean it up and and re-gasket a few things, but after doing a compression test, the numbers didn't look great.

I misplaced the paper I wrote the figures on, but as I recall they were all in the 100 - 115 psi range. That seemed low, so I decided to tear it down.

Nothing jumped out at me as being out of the ordinary, except a couple of the cam bearings, which I'll get to in a minute. The cylinders were all smooth, with no noticeable crosshatch, so at the very least they'll need a hone.

The rod bearings were showing some wear, but didn't look bad. At least I don't think they look terrible.

Same with the crank bearings.

And none of the bearing surfaces on the cam looked bad.

So, what happened to these two cam bearings?

The same bearing but from a different angle and zoomed in

This one isn't as bad, but still messed up

All the others seem fine.

I have the tool and new cam bearings on order, but I want to know if there's anything else I should be looking for since I have no idea what caused this. I'm still hoping to just be able to do a hone and put in a re-ring kit. Again, this is my first rebuild, and I'm sure I'll have more questions as I move forward, but this is definitely one I'd like some input on.