Logan Horsman

Member

Hey guys, I have a 69 440 HP.

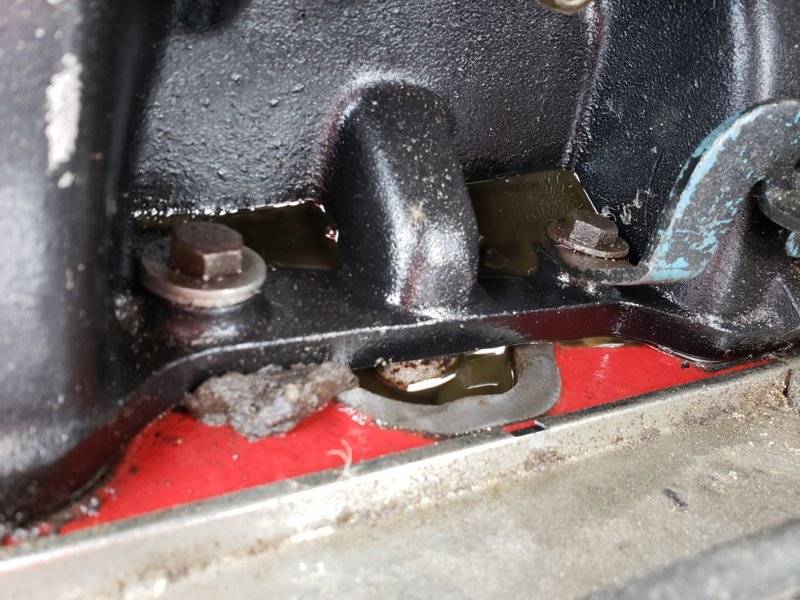

I put an Edelbrock Performer RPM intake on it and I am getting oil coming out the half circle port on the intake side. Why is this? Is this supposed to be blocked off with a special intake gasket?

It seems to be only on the driver side.

I am pretty new to any type of engine work.

Please help!

Thanks in advance

I put an Edelbrock Performer RPM intake on it and I am getting oil coming out the half circle port on the intake side. Why is this? Is this supposed to be blocked off with a special intake gasket?

It seems to be only on the driver side.

I am pretty new to any type of engine work.

Please help!

Thanks in advance