I was watching a youtube video from a guy who seems to know what he is doing. In it he cleans a new oil pump and packs it with vaseline to help the pump create suction and prevent cavitation when first installed. I had never seen this and wondered if this was good, bad, indifferent or even necessary? What do you think about this and his recommendations?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Oil pump priming. Vaseline needed?

- Thread starter Kent mosby

- Start date

-

69 M-CODE CUDA

Well-Known Member

Yes, that's good advice. I was taught that by an old Hudson mechanic, and is what I've done in the past when first starting up a rebuilt engine. I know many guys that do that as well. I plan to do that with my 440 when it's time to fire that up again.

Completely UN - necessary!

Take your drill and oil pump priming rod, insert and spin. Have a friend turn the crank to get oil everywhere! Your done.

Vasoline? That guy has got to be kidding us!

If your oil pump, old or new, needs Vasoline to help create suction, then the pump is bad. Once the vasoline gets dispersed into the engine (that can’t be good!) what will you do once the oil pump is cleared of it? Take off the pump and re apply vasoline for the spring start up? Non sense! Total nonsense!

Take your drill and oil pump priming rod, insert and spin. Have a friend turn the crank to get oil everywhere! Your done.

Vasoline? That guy has got to be kidding us!

If your oil pump, old or new, needs Vasoline to help create suction, then the pump is bad. Once the vasoline gets dispersed into the engine (that can’t be good!) what will you do once the oil pump is cleared of it? Take off the pump and re apply vasoline for the spring start up? Non sense! Total nonsense!

I used engine assembly lube. It's made for that kind of thing.

Garys72Duster

Well-Known Member

Don't know that it's necessary, although the cleaning is a good idea. I have always primed my pump with a drill, or even a speed wrench works too. Then I rotate the engine several turns to get oil flowing throughout the oil system, while priming. Also re prime just before first start up.

69_340_GTS

Well-Known Member

We always fill the oil filter with oil, and then seal the top with a bunch of vaseline before putting it on the engine. This is (obviously) not necessary unless the filter mounts sideways. The vaseline or assy lube mixes with the motor oil and won't hurt a thing.

You use vasoline to seal the oil filter?!?!We always fill the oil filter with oil, and then seal the top with a bunch of vaseline before putting it on the engine. This is (obviously) not necessary unless the filter mounts sideways. The vaseline or assy lube mixes with the motor oil and won't hurt a thing.

I dab my finger in the oil, used or fresh and run it around the oil filter seal. Never a problem.

From the oil pump horror stories I've heard it wouldn't be a bad idea to remove the cover of the small block pumps, clean, and pack with a little lube.

Last edited:

dibbons

Well-Known Member

You mean the small block oil pumps can't be taken apart like the big block ones?

69_340_GTS

Well-Known Member

No, you're not getting what I'm saying. If you fill an oil filter with oil, and then tip it on its side, what happens? Sealing the entire top with a bunch of Vaseline or assy lube, you don't lose a drop.You use vasoline to seal the oil filter?!?!

I dab my finger in the oil, used or fresh and run it around the oil filter seal. Never a problem.

I read the same thing somewhere. I would use something like TMM posted, itll thin/dilute

Ya I was wrong, the big block pumps have to be taken apart also.You mean the small block oil pumps can't be taken apart like the big block ones?

It isn't required on a big block Mopar. That is an old Chevy trick where the oil pump is hidden inside the pan and you really don't want to take it all apart to get it to prime. On a big block Mopar the pump will prime 99% of the time if some oil is poured into the oil filter. Sometimes you'll get an air bubble in the system but those are easy to get rid of. Just crack open the filter and spin the pump to purge the air and then you'll be primed. The guy who did the video most likely isn't a Mopar big block guy, maybe a long time Chevy mechanic who just uses the same trick for every engine whether it needs it or not.

mopardude318

Well-Known Member

I've heard of that. I don't think its unreasonable. But yea, you can just prime like rumblefish says.

Inertia

Well-Known Member

GM uses a different type of spur gear pump that may poss drain. With loose tlerences, it maybe possible to lose it's prime.

Mopar uses a gear-rotor type pumps, similar to automatic transmission that are nearly impossible to lose prime.

https://www.hemmings.com/magazine/hmn/2011/09/Oil-Pumps/3703441.html

Mopar uses a gear-rotor type pumps, similar to automatic transmission that are nearly impossible to lose prime.

https://www.hemmings.com/magazine/hmn/2011/09/Oil-Pumps/3703441.html

IMO, both Vasoline and Lubriplate are both too thick. I have seen Lubriplate stop an oil pump from picking up prime, first hand. Vasoline is even thicker. Prime the oil pump with what it was intended to pump. MOTOR OIL.

Now, I would endorse disassembling the pump, which you should do anyway to check and correct clearances, and putting a THIN FILM of Vasoline as an initial lubricant. There would be nothing wrong with THAT. But to prime it totally with Vasoline.......eh......no.

Now, I would endorse disassembling the pump, which you should do anyway to check and correct clearances, and putting a THIN FILM of Vasoline as an initial lubricant. There would be nothing wrong with THAT. But to prime it totally with Vasoline.......eh......no.

Daves69

Well-Known Member

After you inspect the pump rotor clearances, just reassemble with clean oil. Poor some new oil in the intake port and spin the rotor to pull it in. Bolt it on. Fill the filter as much as you're comfortable with, spin it on and rock and roll.

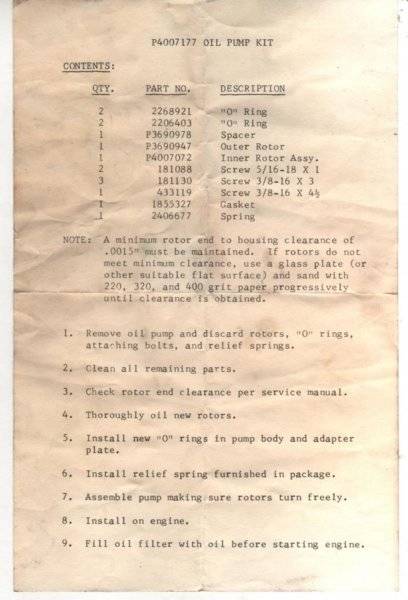

Ya' remember the "long rotor" oil pump kit DC sold? No special lube required...…..

Ya' remember the "long rotor" oil pump kit DC sold? No special lube required...…..

GM uses a different type of spur gear pump that may poss drain. With loose tlerences, it maybe possible to lose it's prime.

Mopar uses a gear-rotor type pumps, similar to automatic transmission that are nearly impossible to lose prime.

https://www.hemmings.com/magazine/hmn/2011/09/Oil-Pumps/3703441.html

Exactly. That is why I said the video was probably made by a Chevy guy who was used to working on spur gear pumps. Just because that is the way to do it on a Chevy doesn't mean it needs to be done that way on a Mopar.

Air in the system? These are positive displacement pumps and will pump air. You dont need to bleed the air out of the system to get it to pump like you would with a centrifugal pump.

No need to do anything to the pump. If its a new engine or been sitting a long time you should prime with a priming shaft / drill. The filter does not have to be completely full when you put it on. Fill it enough to soak the element and thats good enough.

Bottom line is the pump should be able to pick up suction even when dry. If it wont then the pump or pickup has issues.

No need to do anything to the pump. If its a new engine or been sitting a long time you should prime with a priming shaft / drill. The filter does not have to be completely full when you put it on. Fill it enough to soak the element and thats good enough.

Bottom line is the pump should be able to pick up suction even when dry. If it wont then the pump or pickup has issues.

Hellrats

Just another dumbass

Never had an issue with a Mopar pump like you guys are talking about. Now in my other life... I worked on British Leyland cars... that was hell. If those stupid cars sat for too long the pump would not pick up oil at all. So we would have to removed the spark plugs and have someone crank the engine over while someone else would blow air into the dip stick tube (with the fill cap removed) until the pump would start to work. There is no way your gonna drop the pan and fill the pump on those stupid cars.

I was watching a youtube video from a guy who seems to know what he is doing. In it he cleans a new oil pump and packs it with vaseline to help the pump create suction and prevent cavitation when first installed. I had never seen this and wondered if this was good, bad, indifferent or even necessary? What do you think about this and his recommendations?

Why youtube ? Do you not have the service manuals/ performance books to build a performance engine.

IMO you are setting yourself for failure with the build if you are relying on YouTube.

Big block Mopar oil pump WILL prime 99.999 % of the time with oil in the filter and 99 % without oil in filter( not recommended)

I am not relying on YouTube. I have service manuals plus Andy’s book and years of experience. I had never seen the Vaseline idea before. We can always learn from the wisdom of others. YouTube is just another medium for disseminating information but not the answer for everything. Check and more importantly double check the source before believing anything or anyone.

3 words, prelube, prelube, prelube.

No pump packing needed.3 words, prelube, prelube, prelube.

-