You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Opinions on valve keepers..... (poll)

- Thread starter 318willrun

- Start date

-

Interesting thread. I was taught valves should rotate for the obvious benefits. Is that still true? Are there other factors that rotate the valves beyond the keeper issue? Am unaware of any valve issues due to them not rotating.

yellow rose

Overnight Sensation

Interesting thread. I was taught valves should rotate for the obvious benefits. Is that still true? Are there other factors that rotate the valves beyond the keeper issue? Am unaware of any valve issues due to them not rotating.

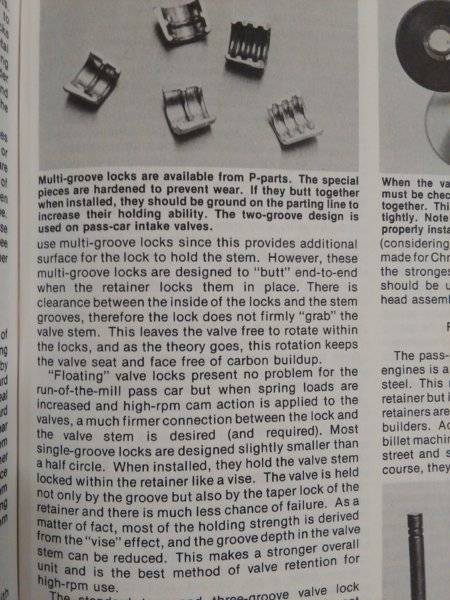

Im not a fan of letting the valves rotate. But that's what some of the keepers were designed to do. With multiple grooves and the keepers butting the valve will spin in the retainer like the knob on a shithouse door. That may be ok for a dead stock deal (I say don't let the rotate) but on ANY performance deal I don't want the valve moving. There is no reason to add another harmonic into the valve train that just doesn't need to be there.

Then grab a single groove lock that doesn't butt and put the retainer on and you won't be able to turn the valve.

Back in the day, the engineers wanted the valves turning to keep carbon from building up on the seats. Today, if you have carbon issues on a seat you need to fix your engine. Plus, engine speeds were much lower than they are today.

Also, multi groove locks with solid lifter cams is a disaster waiting to happen.

The design of the keeper have nothing to do with valve rotation, whether it be a one or multiple groove or whether or not the keepers are touching.... The whole assemble twists, valve, keepers and spring retainer. Please show some me info on the web, I like to read up on this........I think there's rumors that yellow rose is in training to be rusty Rat Rods assistant technical editor...

furrystump

Well-Known Member

- Joined

- Nov 13, 2004

- Messages

- 2,103

- Reaction score

- 1,699

The video is crazy!

yellow rose

Overnight Sensation

The design of the keeper have nothing to do with valve rotation, whether it be a one or multiple groove or whether or not the keepers are touching.... The whole assemble twists, valve, keepers and spring retainer. Please show some me info on the web, I like to read up on this........

Uh, you'd be wrong. The keepers not grabbing the valve induces rotation. Look around and find the info. It's there.

In fact, call Trend, or Crower, or just about any company that makes and/or sells locks.

.Uh, you'd be wrong. The keepers not grabbing the valve induces rotation. Look around and find the info. It's there.

In fact, call Trend, or Crower, or just about any company that makes and/or sells locks.

yr your in box is full. When you get a chance conversate me.

http://webbut.unitbv.ro/BU2011/Series I/BULETIN I/Jelenschi_L.pdfUh, you'd be wrong.

2.1. The importance of valve rotation

The main scope of the valve and tappet

rotation is to reduce the wear, the friction

and to increase the life period of the

components. To maintain the conical valve

face and seat clean of carbon or soot deposit

that might appear on surfaces during valve

opening. To uniform the thermal stress of

the valve head because of the asymmetry

exhaust manifold and uniform the wear of

the conical face, providing a good sealing

of the cylinder [4].

https://www.quora.com/What-is-valve-rotation

engines? If so, then often [if not always] the valves designed to slowly rotate along their longitudinal axis when the engine is working in order for the working surface of their bevels which touch the valve seats to have more even wear: if the valves touch their seats in the same position every time the valve closes there is risk that the working surface can lose it’s roundness quickly.

How much more proof do you want...where is yours?

As you suggested I did Crower @ 619.661.6477 and talked to Shane, tec support, the keepers have nothing to do with the valves rotating or not! The valves rotate because of frequency and harmonics...plain and simple. Don't you feel better knowing the truth?

dartfreak75

Restore it, Dont part it!

The springs have a twisting action made into them it is how they are. The keepers and valve grooves have very little with not letting the valve twist. The rotation action helps keep the valve and seat clear of debris to ensure good sealing and even wear. Yes some of the older engines and aircraft have rotators on the exhaust, not many cars that I am aware of......

Wow that is very interesting didn't know they rotated like that. So I read alot of ppl ditch the rotators when they build there heads is that a bad idea? After seeing that maybe we should keep them?

TrailBeast

AKA Mopars4us on Youtube

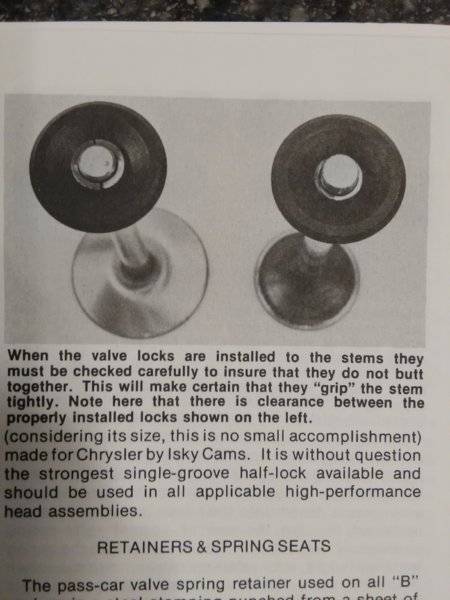

I like the gap because it tells me the keeper has a good solid grip on the stem, and won't beat the grooves out.

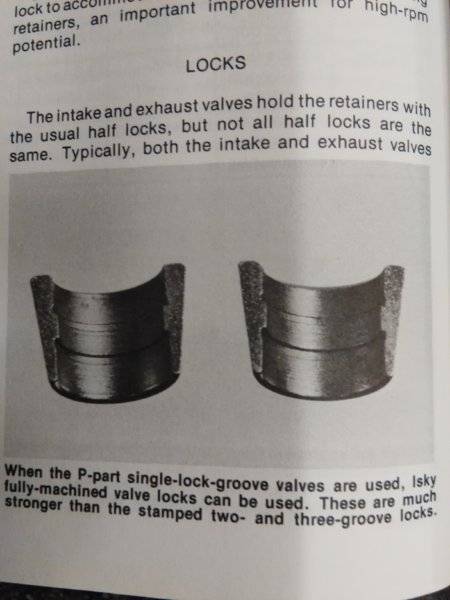

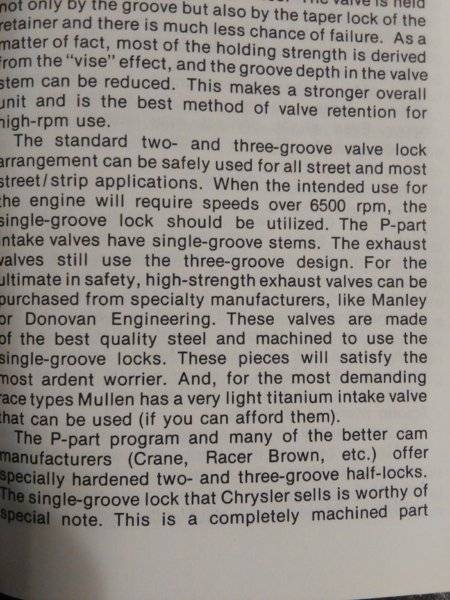

No need to call Saul or search the web ......From the trusty Mopar Performance book by Larry Schreib (an excellent resource to this day) Printed in 1978, but surely common knowledge years prior. One might ask why multi-grooves were designed to butt together then, but not me. Its explained in the good book!:

......From the trusty Mopar Performance book by Larry Schreib (an excellent resource to this day) Printed in 1978, but surely common knowledge years prior. One might ask why multi-grooves were designed to butt together then, but not me. Its explained in the good book!:

Last edited:

-